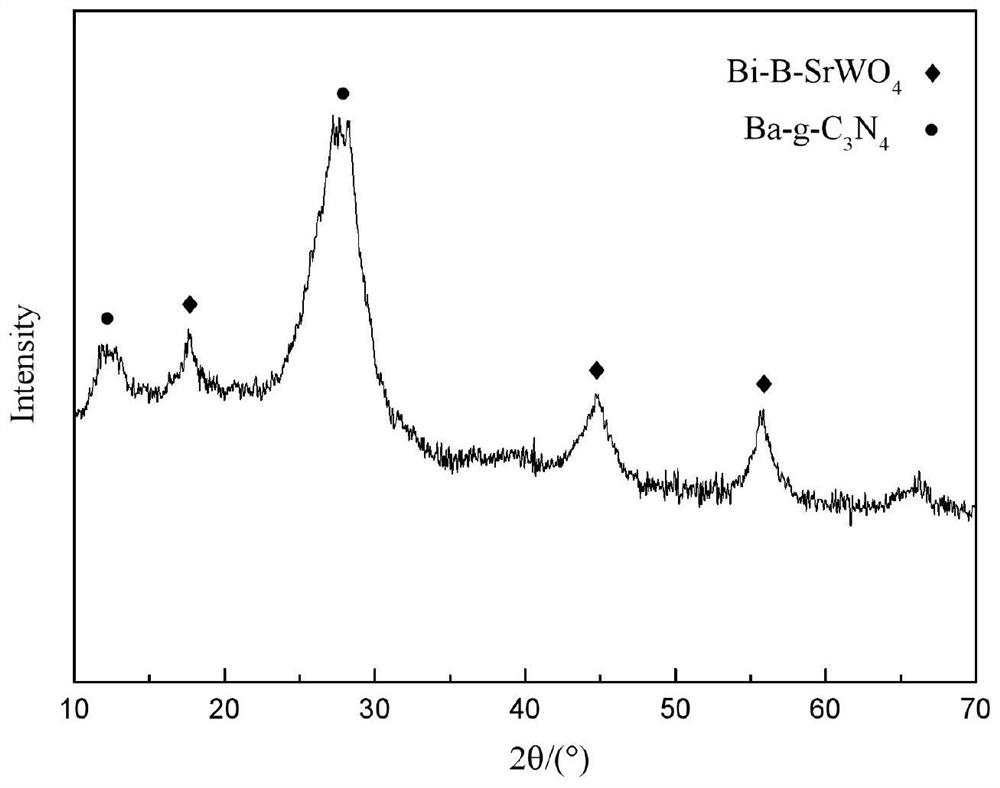

Bi-B doped SrWO4/Ba-g-C3N4 composite nitrogen fixation photocatalyst and preparation method of Bi-B doped SrWO4/Ba-g-C3N4 composite nitrogen fixation photocatalyst

A ba-g-c3n4, photocatalyst technology, applied in the field of photocatalysis applications, can solve the problems of poor nitrogen fixation performance and low utilization rate of visible light, and achieve the effect of optimizing the energy band structure and improving the capture and conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

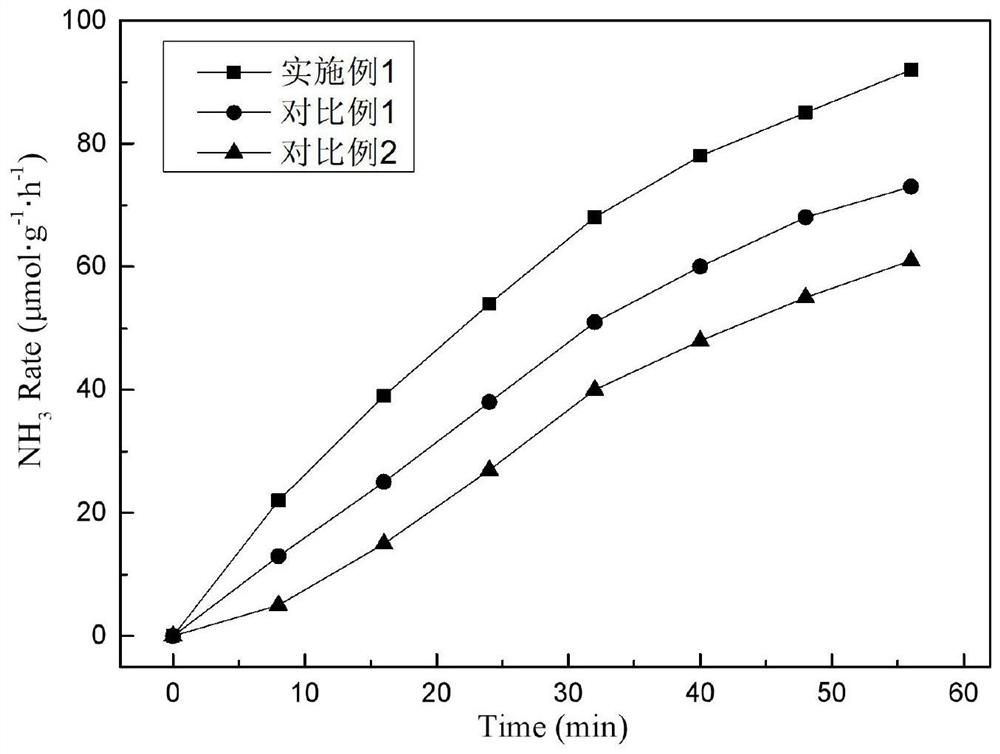

Embodiment 1

[0023] Step one: the Ba(OH) of 4g melamine, 0.89g thiourea and 1.34g 2 After uniform mixing, put it into an aluminum oxide crucible, raise the temperature to 550°C in a muffle furnace, calcinate for 4-6 hours, and grind the obtained block sample in a mortar for 30-40 minutes after cooling to room temperature to obtain powdered Ba -g -C 3 N 4 .

[0024] Step 2: 1.1g of SrCl 2 ·6H 2 O and 1.64g Na 2 WO 4 2H 2 O was dissolved in 22ml and 8.2ml ethylene glycol respectively, and then to SrCl 2 ·6H 2 Add 2.58g trimethyl borate to the ethylene glycol solution of O, and add Na to the mixed solution dropwise at a rate of 1ml / min in a water bath at 50-60°C after ultrasonication for 10-15min. 2 WO 4 2H 2 O ethylene glycol solution, continue to stir for 20-30min after the dropwise addition, then add 2.4g of Ba-g-C to the mixed solution 3 N 4 and 0.6g BiCl 3 And ultrasonic for 5-8min, casually put the mixed solution in a polytetrafluoroethylene-lined reaction kettle at a temp...

Embodiment 2

[0026] Step one: the Ba(OH) of 6g melamine, 0.86g thiourea and 0.97g 2 After uniform mixing, put it into an aluminum oxide crucible, raise the temperature to 550°C in a muffle furnace, calcinate for 4-6 hours, and grind the obtained block sample in a mortar for 30-40 minutes after cooling to room temperature to obtain powdered Ba -g -C 3 N 4 .

[0027] Step two: the SrCl of 1.29g 2 ·6H 2 O and 1.59g Na 2 WO 4 2H 2 O was dissolved in 25.8ml and 8ml ethylene glycol respectively, and then to SrCl 2 ·6H 2 Add 2.02g trimethyl borate to the ethylene glycol solution of O, and add Na to the mixed solution dropwise at a rate of 1ml / min in a water bath at 50-60°C after ultrasonication for 10-15min. 2 WO 4 2H 2 O ethylene glycol solution, continue to stir for 20-30min after the dropwise addition, then add 3.6g of Ba-g-C to the mixed solution 3 N 4 and 0.53g BiCl 3 And ultrasonic for 5-8min, casually put the mixed solution in a polytetrafluoroethylene-lined reaction kettle a...

Embodiment 3

[0029] Step one: the Ba(OH) of 5g melamine, 1.1g thiourea and 1.57g 2 After uniform mixing, put it into an aluminum oxide crucible, raise the temperature to 550°C in a muffle furnace, calcinate for 4-6 hours, and grind the obtained block sample in a mortar for 30-40 minutes after cooling to room temperature to obtain powdered Ba -g -C 3 N 4 .

[0030] Step two: the SrCl of 1.36g 2 ·6H 2 O and 1.97g Na 2 WO 4 2H 2 O was dissolved in 27.2ml and 9.8ml ethylene glycol respectively, and then to SrCl 2 ·6H 2 Add 2.95g trimethyl borate to the ethylene glycol solution of O, and add Na to the mixed solution dropwise at a rate of 1ml / min in a water bath at 50-60°C after ultrasonication for 10-15min. 2 WO 4 2H 2 O ethylene glycol solution, continue to stir for 20-30min after the dropwise addition, then add 3g of Ba-g-C to the mixed solution 3 N 4 and 0.72g BiCl 3 And ultrasonic for 5-8min, casually put the mixed solution in a polytetrafluoroethylene-lined reaction kettle at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com