Preparation method of moisture-curable polyurethane hot melt adhesive for textile compounding

A polyurethane hot-melt adhesive and moisture-curing technology, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem that the peel strength and softness cannot be improved at the same time, and achieve strong peel strength and improved Softness, the effect of reducing the Shore hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

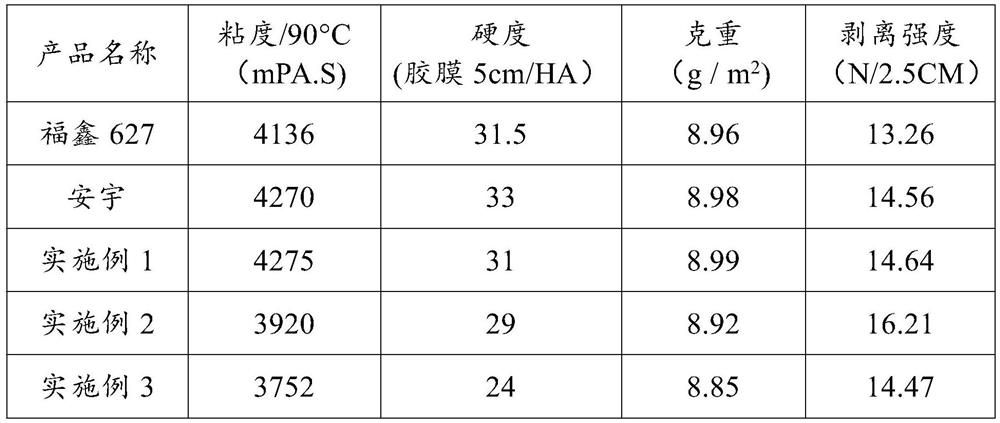

Examples

Embodiment 1

[0032]A preparation method of moisture-curing polyurethane hot melt adhesive for textile composites, including the following steps:

[0033](1) Combine 5.2 parts of polyethylene phthalate glycol (parts by weight, the same below), 11.1 parts of sebacic acid polyester polyol, 12.0 parts of adipic acid polyester polyol and polyether polyol 48.9 parts of polyol mixture, stirred and mixed with 0.05 parts of antioxidant, then heated to 127°C, dehydrated for 70 minutes under vacuum ≤100Pa;

[0034](2) Cool down to 75°C, add 21.75 parts of 4,4'-diphenylmethane diisocyanate (MDI), 0.5 part of catalyst bismorpholinyl diethyl ether, vacuum degree≤100Pa, reaction temperature 85~90℃ Stir and react for 180min under conditions;

[0035](3) Add 0.5 part of trimethylolpropane, a chain extender, and continue to react for 30 minutes under vacuum ≤100Pa and temperature 85~90℃;

[0036](4) The material is quickly discharged under the protection of nitrogen and packaged in an aluminum foil bag, and cured at room tem...

Embodiment 2

[0038]A preparation method of moisture-curing polyurethane hot melt adhesive for textile composites, including the following steps:

[0039](1) Combine 8 parts of phthalic anhydride polyester polyol, 6.5 parts of sebacic acid polyester polyol, 15.6 parts of adipic acid polyester polyol, and 46.9 parts of propylene oxide polyether polyol in parts by mass. Stir and mix 0.05 parts of oxygen agent, heat to 120°C, and dehydrate for 70min under the vacuum degree of less than 100Pa;

[0040](2) Cool down to 80°C, add 22.45 parts of 4,4'-diphenylmethane diisocyanate (MDI), 0.35 parts of catalyst bismorpholinyl diethyl ether, under vacuum ≤100Pa, reaction temperature 85~90℃ Stir and react for 150min under the conditions;

[0041](3) Cool down to 90°C, add 0.5 part of trimethylolpropane, a chain extender, and continue the reaction for 30 minutes at a vacuum degree of less than 100 Pa and a temperature of 100°C;

[0042](4) The material is quickly discharged under the protection of nitrogen and encapsulat...

Embodiment 3

[0044]A method for preparing a moisture-curing polyurethane hot melt adhesive for textile composite, including the following steps:

[0045](1) Combine 7 parts of phthalic anhydride polyester polyol, 12 parts of sebacic acid polyester polyol, 12.6 parts of adipic acid polyester polyol and 40.6 parts of propylene oxide polyether polyol in parts by mass. Stir and mix 0.05 parts of oxygen agent, heat to 120°C, and dehydrate for 70min under the vacuum degree of less than 100Pa;

[0046](2) Cool down to 75°C, add 27.25 parts of 4,4'-diphenylmethane diisocyanate (MDI), 0.4 part of catalyst, and stir and react for 135min under the conditions of vacuum ≤100Pa and reaction temperature of 85-90°C;

[0047](3) Cool down to 90°C, add 0.5 part of trimethylolpropane, a chain extender, and continue the reaction for 30 minutes at a vacuum degree of less than 100 Pa and a temperature of 100°C;

[0048](4) The material is quickly discharged under the protection of nitrogen and encapsulated in an aluminum foil ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com