All-optical integrated broadband ultrasonic detection device and preparation method

An ultrasonic detection, integrated technology, applied in the direction of measuring device, using sound wave/ultrasonic wave/infrasonic wave to analyze solids, using sound wave/ultrasonic wave/infrasonic wave to analyze materials, etc. It can solve the problem of reduced responsivity, small dynamic range, and limited use of space and other problems, to achieve the effect of simple preparation method, small dynamic range and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the all-optical integrated broadband ultrasonic testing device is as follows:

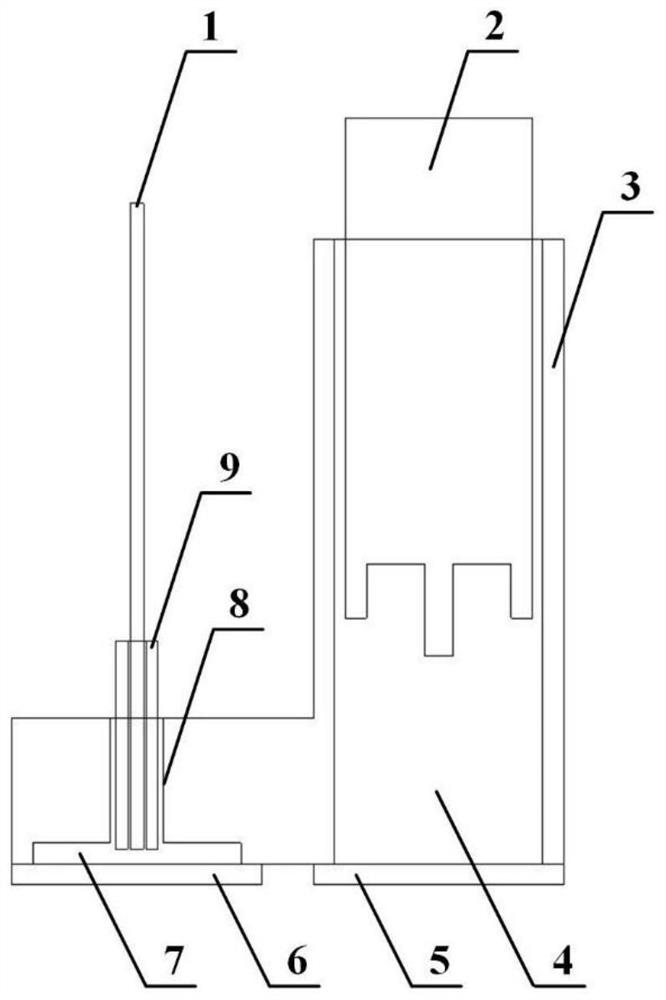

[0035] S1. Using high-precision 3D printing technology to make the L-shaped housing 3, the material of the L-shaped housing 3 is engineering plastics (ABS, PC, nylon) or photosensitive resin (epoxy resin, resin somos11122 and 19120). The L-shaped housing includes a vertical section and a horizontal section. The vertical section is provided with a first through hole 4 along the vertical direction, and the horizontal section is provided with a second through hole 8 along the vertical direction: the diameter of the first through hole 4 is The second through hole 8 has a diameter of 2.6 mm and a length of 3-8 mm and is used for assembling a broadband ultrasonic receiving end. In order to improve the response sensitivity of the broadband ultrasonic receiving end, a circular resonant cavity 7 with a diameter of 10 mm and a thickness of 0.4 to 1 mm is arranged at the botto...

Embodiment 1

[0042] S1. The L-shaped casing 3 is manufactured by high-precision 3D printing technology, and the material of the L-shaped casing 3 is ABS plastic. In the L-shaped housing 3, a first through hole 4 and a second through hole 8 are respectively arranged in the vertical direction: the first through hole 4 has a diameter of 10mm and a length of 25mm, and is used for assembling a broadband ultrasonic excitation end; The hole 8 has a diameter of 2.6 mm and a length of 3 mm, and is used for assembling a broadband ultrasonic receiving end. In order to improve the response sensitivity of the broadband ultrasonic receiving end, a circular resonant cavity 7 with a diameter of 10 mm and a thickness of 0.4 mm is provided. The circular resonant cavity 7 is coaxial with the second through hole 8. Body 3 lower ends are flush.

[0043] S2. Select the high-power optical fiber 2 as the laser transmission fiber of the nanosecond pulse laser. The core diameter of the high-power optical fiber 2 i...

Embodiment 2

[0046] S1. The L-shaped casing 3 is manufactured by using high-precision 3D printing technology, and the material of the L-shaped casing 3 is epoxy resin. In the L-shaped housing 3, a first through hole 4 and a second through hole 8 are respectively arranged in the vertical direction: the first through hole 4 has a diameter of 10mm and a length of 35mm, and is used for assembling a broadband ultrasonic excitation end; The hole 8 has a diameter of 2.6 mm and a length of 8 mm, and is used for assembling a broadband ultrasonic receiving end. In order to improve the response sensitivity of the broadband ultrasonic receiving end, a circular resonant cavity 7 with a diameter of 10 mm and a thickness of 1 mm is provided. The circular resonant cavity 7 is coaxial with the second through hole 8. 3 lower ends flush.

[0047] Steps S2 and S3 are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com