Ultrathin large-area solder ball printing process adopting polyimide

A polyimide, large-area technology, applied in the field of semiconductor technology, can solve the problems of bending or fragmentation, difficult process, decomposition and damage, etc., and achieve the effect of reducing process difficulty and process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] An ultra-thin large-area solder ball printing process using polyimide, comprising the following steps:

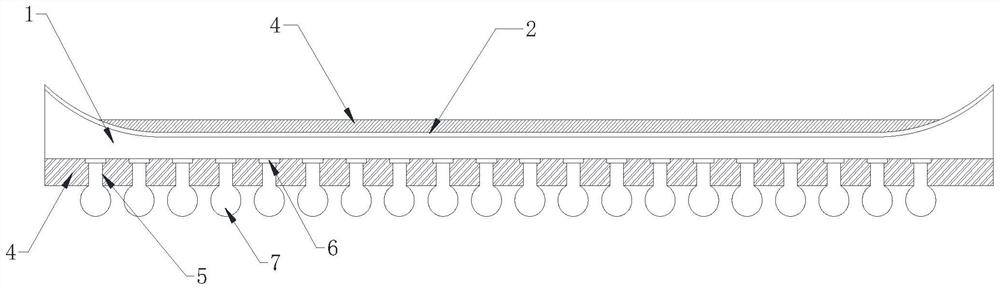

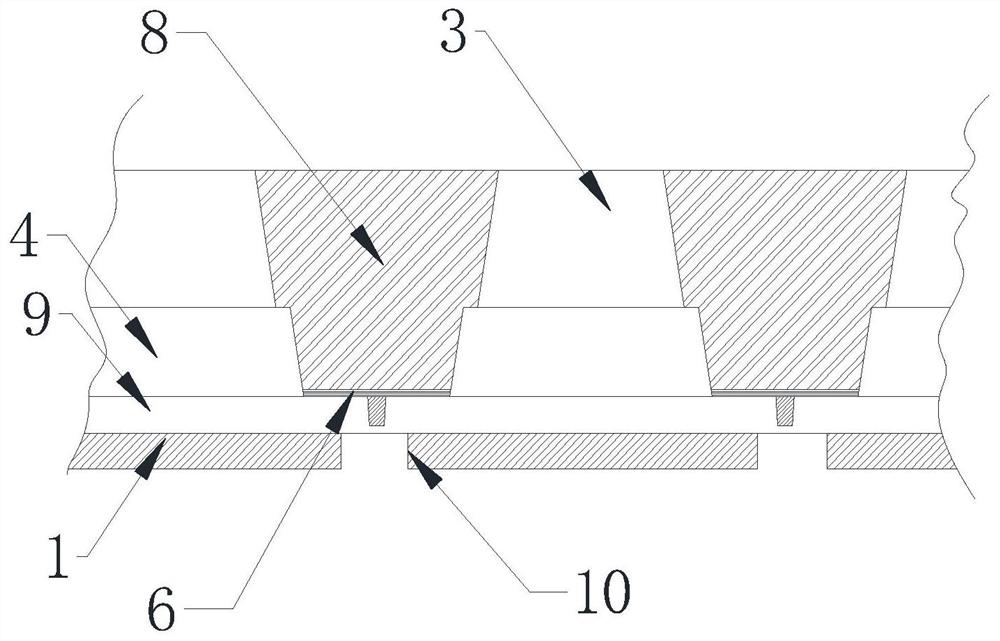

[0047] S1: Complete the contact hole of MOSFET or IGBT wafer 1 that has completed the front ILD process, and form a plug with W-CVD filling and CMP planarization. When the contact size is large, directly and continuously use Ti / Ni / Cu UBM metal contact holes , and generate a sputtered layer 2 on the surface of the wafer 1;

[0048] S2: Wafer 1 completes the lithography process to form UBM PAD 6 and photoresist layer 3, such as figure 1 , figure 2 As shown, wet etching removes the metal stack in the area outside the photoresist, and completes the formation of the UBM PAD 6 area before solder ball printing;

[0049] S3: Coating polyimide 4 on the front side, performing a lithography process to form the edge of the UBM PAD 6, but exposing the second window 10 that is printed with a large area of solder balls in the middle of the UBM;

[0050] S4: complete the bonding...

Embodiment 2

[0059] An ultra-thin large-area solder ball printing process using polyimide, comprising the following steps:

[0060] S1: Complete the contact hole of MOSFET or IGBT wafer 1 that has completed the front ILD process, and form a plug with W-CVD filling and CMP planarization. When the contact size is large, directly and continuously use Ti / Ni / Cu UBM metal contact holes , and generate a sputtered layer 2 on the surface of the wafer 1;

[0061] S2: Wafer 1 completes the lithography process to form UBM PAD 6 and photoresist layer 3, such as figure 1 , figure 2 As shown, wet etching removes the metal stack in the area outside the photoresist, and completes the formation of the UBM PAD 6 area before solder ball printing;

[0062] S3: Coating polyimide 4 on the front side, performing a lithography process to form the edge of the UBM PAD 6, but exposing the second window 10 that is printed with a large area of solder balls in the middle of the UBM;

[0063] S4: complete the bondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com