Horizontal double-CNC grinding and detecting integrated machine for medium and large-sized glass panels and machining method thereof

A glass panel, large-size technology, applied in the direction of grinding racks, grinding machine tools, grinding tools, etc., can solve the problems of medium and large-sized glass panel damage, low degree of automation, and unfavorable production efficiency, so as to achieve high work efficiency, The effect of reducing labor intensity and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

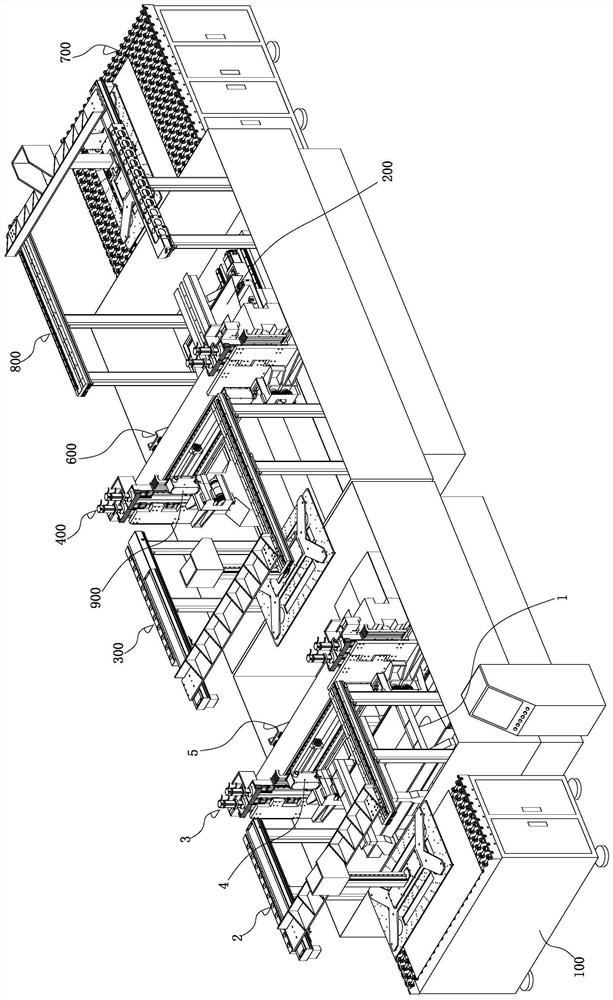

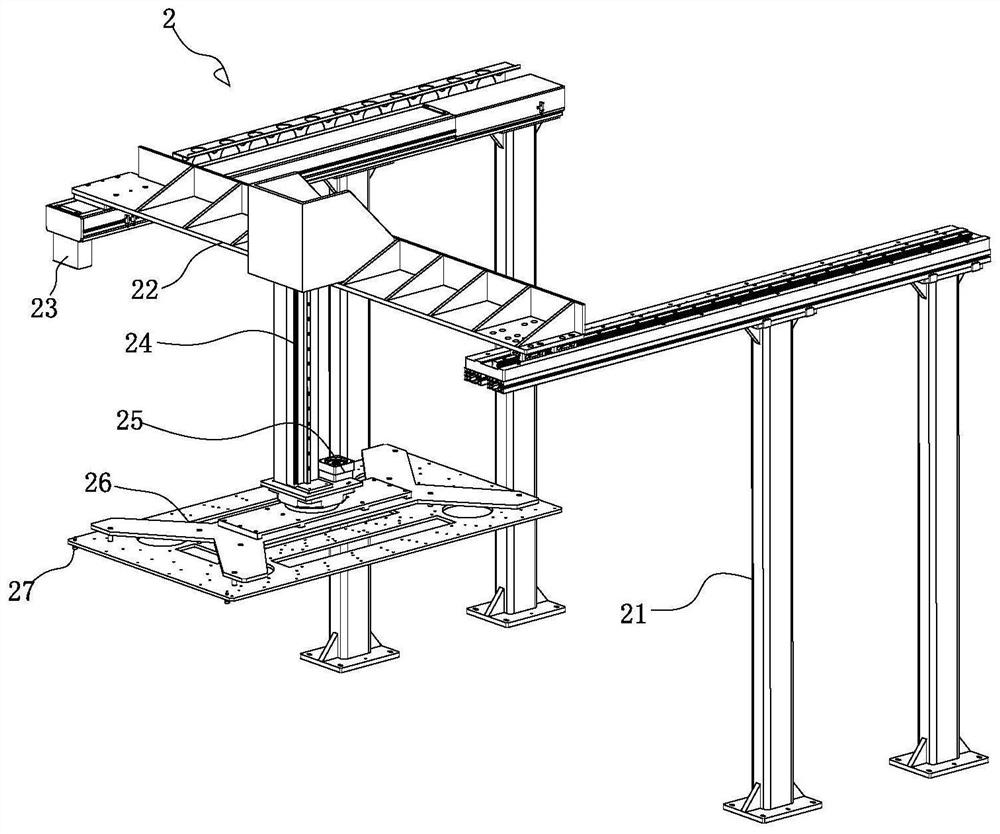

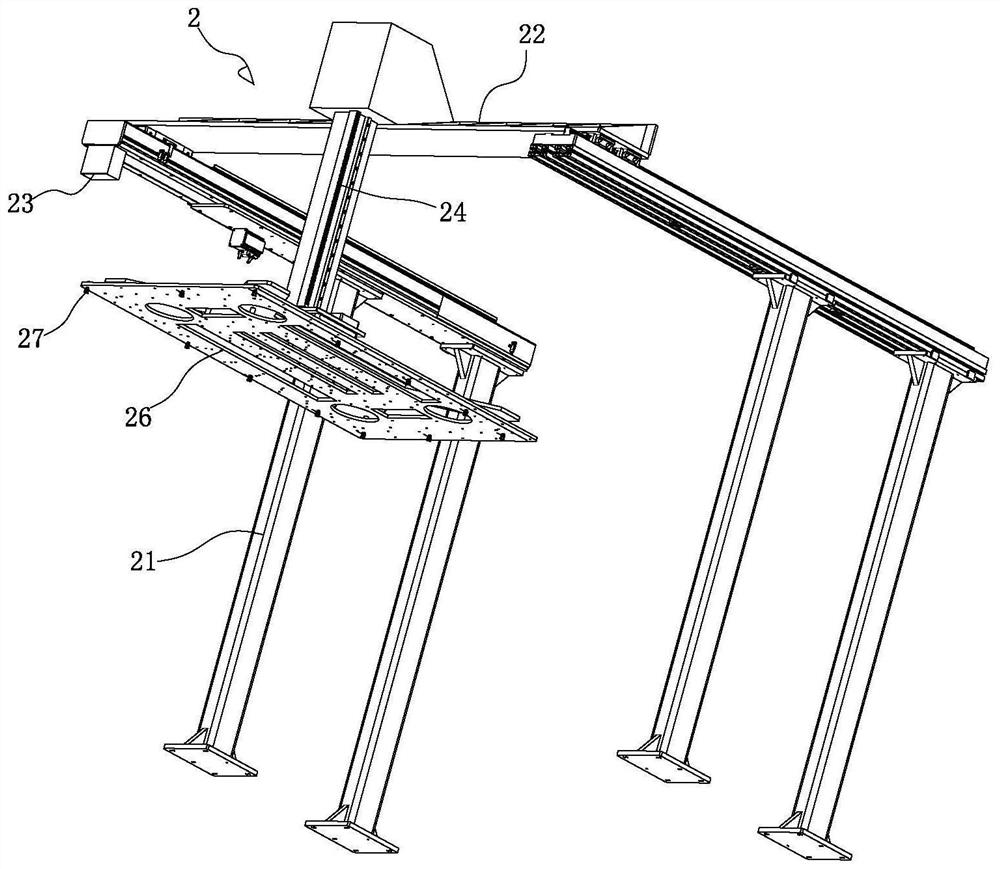

[0041] See Figure 1-23As shown, it is a horizontal double CNC grinding and inspection machine for medium and large-sized glass panels, which includes: a feeding docking station 100, and a first adsorption load transfer work platform 1 installed on the side of the feeding docking station 100 and the loading and transporting manipulator 2 for transferring the medium and large-sized glass panels carried on the loading docking platform 100 to the first adsorption load transfer work platform 1, and for the first adsorption load transfer work platform 1 1 A first horizontal CNC grinding device 3 that simultaneously grinds the upper and lower end surfaces of the two long sides of the medium and large-sized glass panel, at least one of which is installed at the front end of the first horizontal CNC grinding device 3 and is connected with the first adsorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com