Method for treating tank cleaning oil sludge

A technology for sludge and tank cleaning, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as separation, and achieve the effects of high safety, low cost and little secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for processing tank cleaning oil sludge, comprising the following steps:

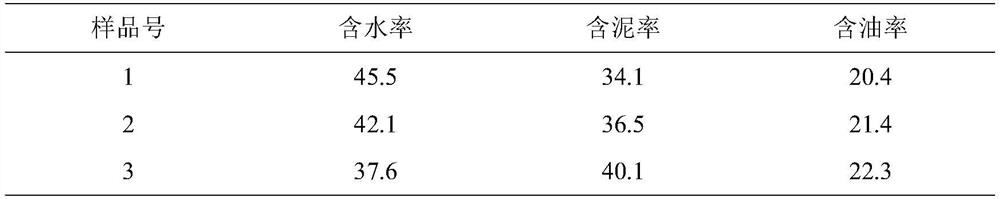

[0027] Step 1: Use a screen with a mesh size of 2 mm to filter the No. 1 tank cleaning sludge to remove impurities, and seal it for use;

[0028] Step 2: According to the ratio of solid-liquid mass ratio of 1:3, water is added to the clear tank sludge, and stirred evenly to form a solid-liquid mixture;

[0029] Step 3: Add a cleaning agent to the solid-liquid mixture, then wash at 80°C for 30 minutes, and separate layers; the weight ratio of the cleaning agent to the solid-liquid mixture is 0.8%; the cleaning agent is in the following weight ratio Composition: polyethylene glycol octylphenyl ether: octadecyl glucoside: sodium hydroxide: polyacrylamide = 20:10:69.9:0.1.

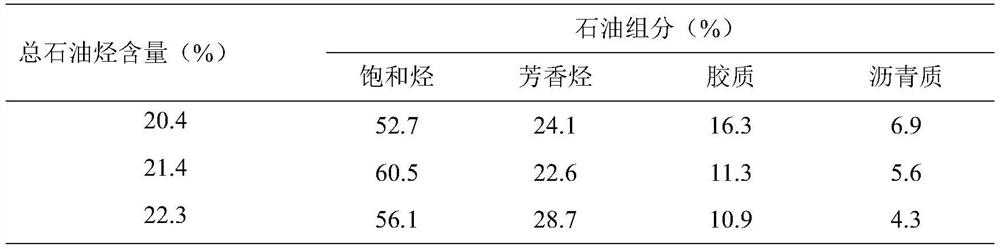

[0030] Step 4: Scrape off the slick oil, drain 80% of the total amount of the supernatant, centrifuge the layered sludge and the remaining supernatant, dry the centrifuged sludge at 40°C, and measure the amount of resid...

Embodiment 2

[0032] A method for processing tank cleaning oil sludge, comprising the following steps:

[0033] Step 1: Use a screen with a mesh size of 2mm to filter the oil sludge in the tank to remove impurities, and seal it for use;

[0034] Step 2: According to the ratio of solid-liquid mass ratio of 1:4, water is added to the clear tank sludge, and stirred evenly to form a solid-liquid mixture;

[0035] Step 3: Add a cleaning agent to the solid-liquid mixture, then wash at 60°C for 50 minutes, and statically separate layers; the weight ratio of the cleaning agent to the solid-liquid mixture is 0.9%; the cleaning agent is composed according to the following weight ratio : polyethylene glycol octylphenyl ether: octadecyl glucoside: sodium hydroxide: polyacrylamide = 20: 10: 69.9: 0.1.

[0036] Step 4: Scrape off the slick oil, drain 90% of the total supernatant, centrifuge the stratified oil sludge and the remaining supernatant, dry the centrifuged oil sludge at 40°C, and measure the r...

Embodiment 3

[0038] A method for processing tank cleaning oil sludge, comprising the following steps:

[0039] Step 1: Use a screen with a mesh size of 3 mm to filter the oil sludge in the tank to remove impurities, and seal it for use;

[0040] Step 2: According to the ratio of solid-liquid mass ratio of 1:5, water is added to the clear tank sludge, and stirred evenly to form a solid-liquid mixture;

[0041] Step 3: Add a cleaning agent to the solid-liquid mixture, then wash at 50°C for 60 minutes, and then separate into layers; the weight ratio of the cleaning agent to the solid-liquid mixture is 1.1%; the cleaning agent is composed according to the following weight ratio : polyethylene glycol octylphenyl ether: octadecyl glucoside: sodium hydroxide: polyacrylamide = 20: 10: 69.9: 0.1.

[0042] Step 4: Scrape off the slick oil, drain 90% of the total supernatant, centrifuge the stratified oil sludge and the remaining supernatant, dry the centrifuged oil sludge at 40°C, and measure the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com