Formula of baking-free brick curing agent and baking-free brick preparation method

A curing agent and non-burning brick technology, which is applied in the field of building materials, can solve the problems of internal structure damage, cement strength decline, strong water permeability, etc., and achieve the effect of alleviating demand pressure and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

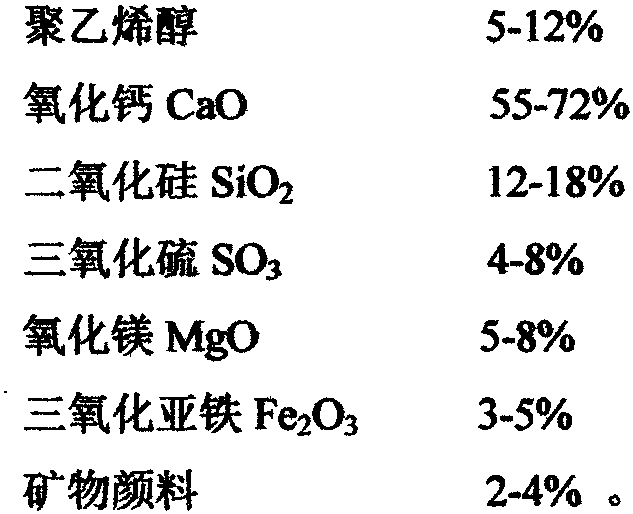

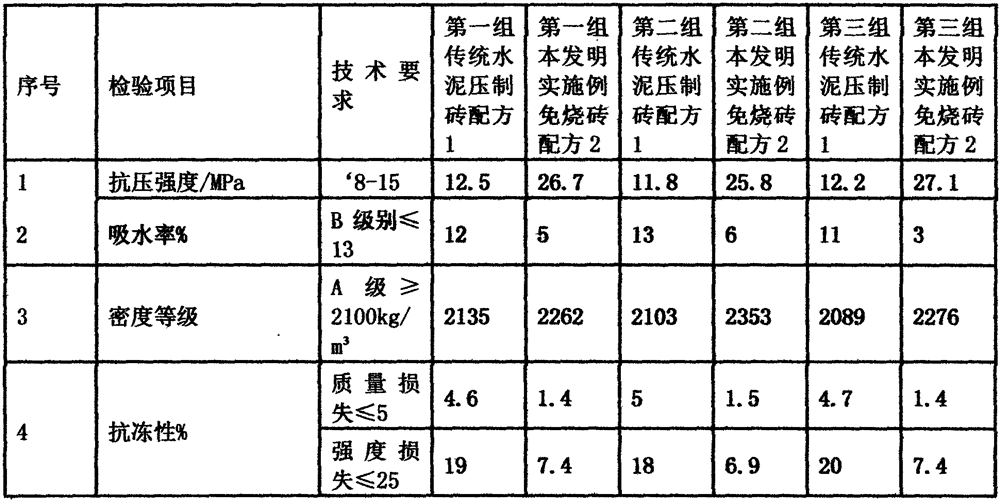

[0008] A curing agent for making non-burning bricks by using solid industrial waste, construction waste and other raw materials. The chemical components in the curing agent formula include: 5-12% polyvinyl alcohol, 55-72% calcium oxide CaO, silicon dioxide SiO 2 12-18%, sulfur trioxide SO 3 4-8%, magnesium oxide MgO 5-8%, ferrous oxide Fe 2 o 3 3-5%, mineral pigment 2-4%, curing agents with different particle gradations can be selected from the above-mentioned components to adjust the configuration within the above-mentioned ratio.

[0009] The mineral pigments are one or more of cinnabar, cinnabar, azurite, stone green, stone yellow, realgar, orpiment, earth yellow, clam powder and mica.

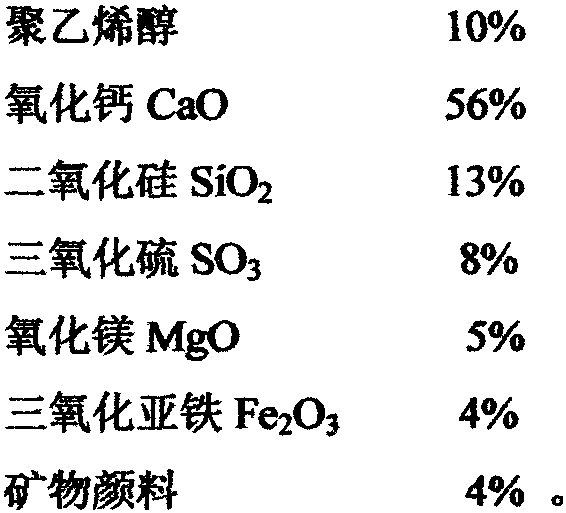

[0010] Preferably, the chemical components in the curing agent formula include: 10% polyvinyl alcohol, 56% calcium oxide CaO, silicon dioxide SiO 2 13%, sulfur trioxide SO 3 8%, magnesium oxide MgO 5%, ferrous oxide Fe 2 o 3 4%, stone green 4%,

[0011] A process for making unb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com