Ammonia washing tower and anti-corrosion shift gas ammonia washing device and process using same

A technology for washing ammonia tower and changing gas, which is applied in the fields of gas processing condensate, gas treatment, petroleum industry, etc., can solve the problems of corrosion of the internal parts and lining of ammonia washing tower, leakage of high-pressure process gas, and high material cost, so as to improve ammonia Gas solubility, saving consumption, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

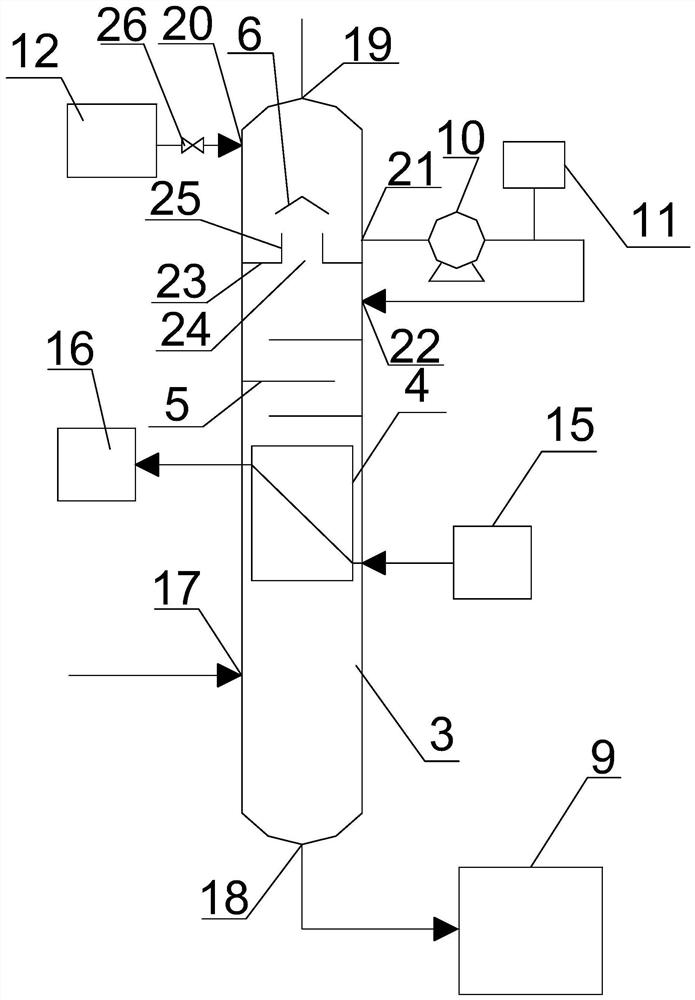

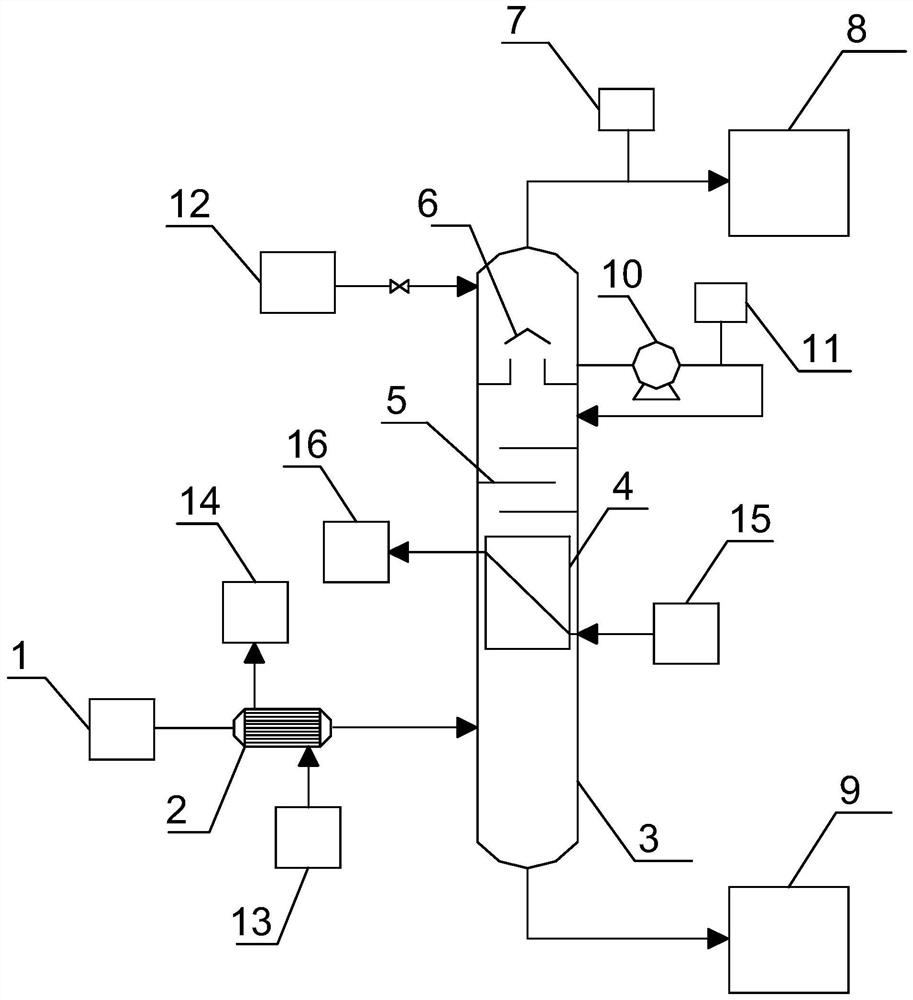

[0048] An ammonia washing tower, the ammonia washing tower 3 sequentially includes a flash section, a cooling section, an ammonia washing section and a pre-wash analysis section from bottom to top; one side of the flash section is provided with a shift gas inlet 17, and the flash section The bottom of the tank is provided with a flash condensate outlet 18; the cooling section includes a chilled water cooler 4 that lowers the temperature of the shift gas and is used to improve the solubility of gas ammonia; the ammonia washing section includes several layers of valve trays 5, And the gas distribution cap assembly located at the top of the float valve tray 5; the top of the prewash analysis section is provided with a shift gas outlet 19, and the upper part of one side of the prewash analysis section is provided with a desalted water inlet 20, and the gas distribution cap assembly The ammonia washing tower wall on the upper side is provided with a pre-washing analysis condensate o...

Embodiment 2

[0050] An ammonia washing tower, the ammonia washing tower 3 sequentially includes a flash section, a cooling section, an ammonia washing section and a pre-wash analysis section from bottom to top; one side of the flash section is provided with a shift gas inlet 17, and the flash section The bottom of the tank is provided with a flash condensate outlet 18; the cooling section includes a chilled water cooler 4 that lowers the temperature of the shift gas and is used to improve the solubility of gas ammonia; the ammonia washing section includes several layers of valve trays 5, And the gas distribution cap assembly located at the top of the float valve tray 5; the top of the prewash analysis section is provided with a shift gas outlet 19, and the upper part of one side of the prewash analysis section is provided with a desalted water inlet 20, and the gas distribution cap assembly The ammonia washing tower wall on the upper side is provided with a pre-washing analysis condensate o...

Embodiment 3

[0052] An ammonia washing tower, the ammonia washing tower 3 sequentially includes a flash section, a cooling section, an ammonia washing section and a pre-wash analysis section from bottom to top; one side of the flash section is provided with a shift gas inlet 17, and the flash section The bottom of the tank is provided with a flash condensate outlet 18; the cooling section includes a chilled water cooler 4 that lowers the temperature of the shift gas and is used to improve the solubility of gas ammonia; the ammonia washing section includes several layers of valve trays 5, And the gas distribution cap assembly located at the top of the float valve tray 5; the top of the prewash analysis section is provided with a shift gas outlet 19, and the upper part of one side of the prewash analysis section is provided with a desalted water inlet 20, and the gas distribution cap assembly The ammonia washing tower wall on the upper side is provided with a pre-washing analysis condensate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com