Method and system for pretreating high-salt preserved szechuan pickle wastewater

A mustard wastewater and pretreatment technology, which is applied in the direction of food industry wastewater treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of high process operation cost, poor pollutant removal effect, long process flow, etc., and achieve reduction pollution concentration, solve the effect of poor nitrification stability and shorten the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

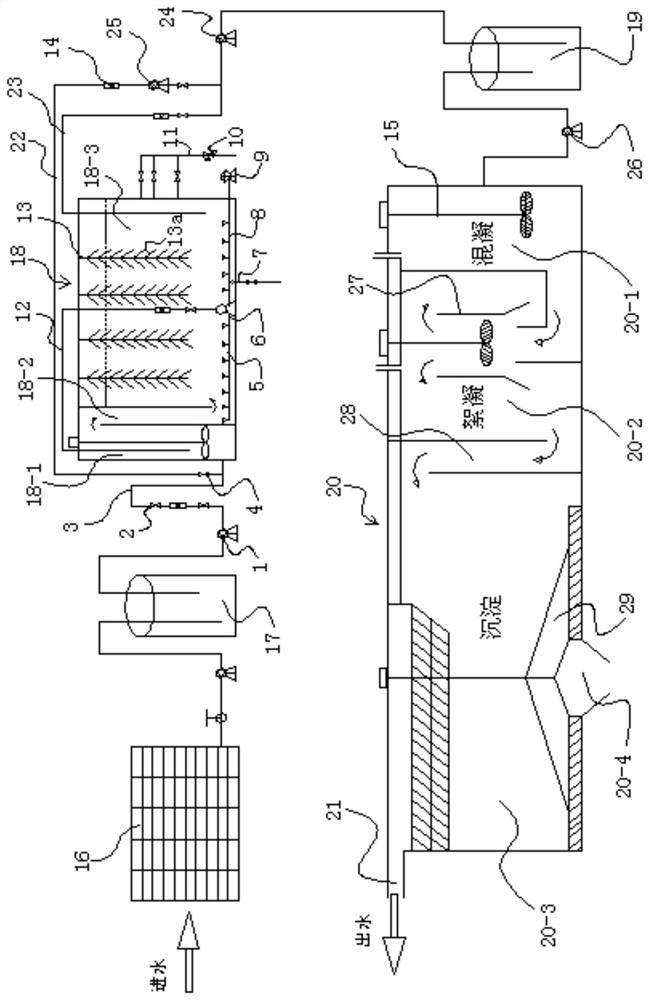

[0034] see figure 1 , figure 2 , the method for high-salt wastewater pretreatment of the present invention adopts the system of high-salt wastewater pretreatment to carry out, specifically as follows:

[0035] A system for pretreatment of high-salt mustard mustard wastewater, the system includes a regulating tank 17 arranged in sequence, a circulating reaction tank 18, an intermediate tank 19, and a sedimentation tank 20. 16, the pipeline is provided with valves and water pumps, and the grid 16 is used to filter out impurities and suspended solids in the waste water to be treated; the downstream of the regulating pool 17 is connected to the circulation reaction pool 18 through the main water inlet pipe 3, the The main water inlet pipe 3 is provided with a first water pump 1 and a first check valve 2, as well as a flow meter for measuring the inflow flow. The first water pump 1 is used to draw water from the regulating pool 17, and the first check valve 2 Used to prevent bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com