Extraction equipment and extraction method for extracting hemicellulose from straws

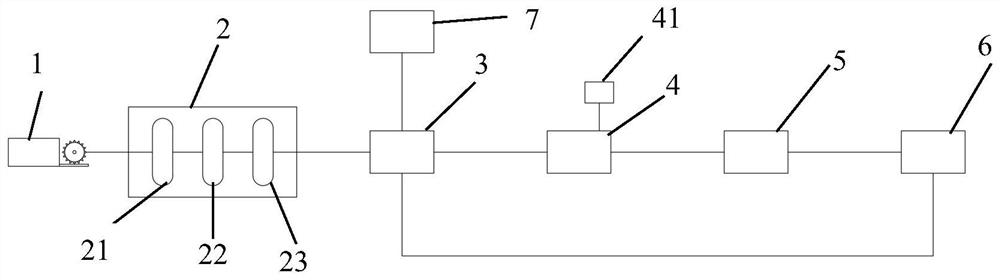

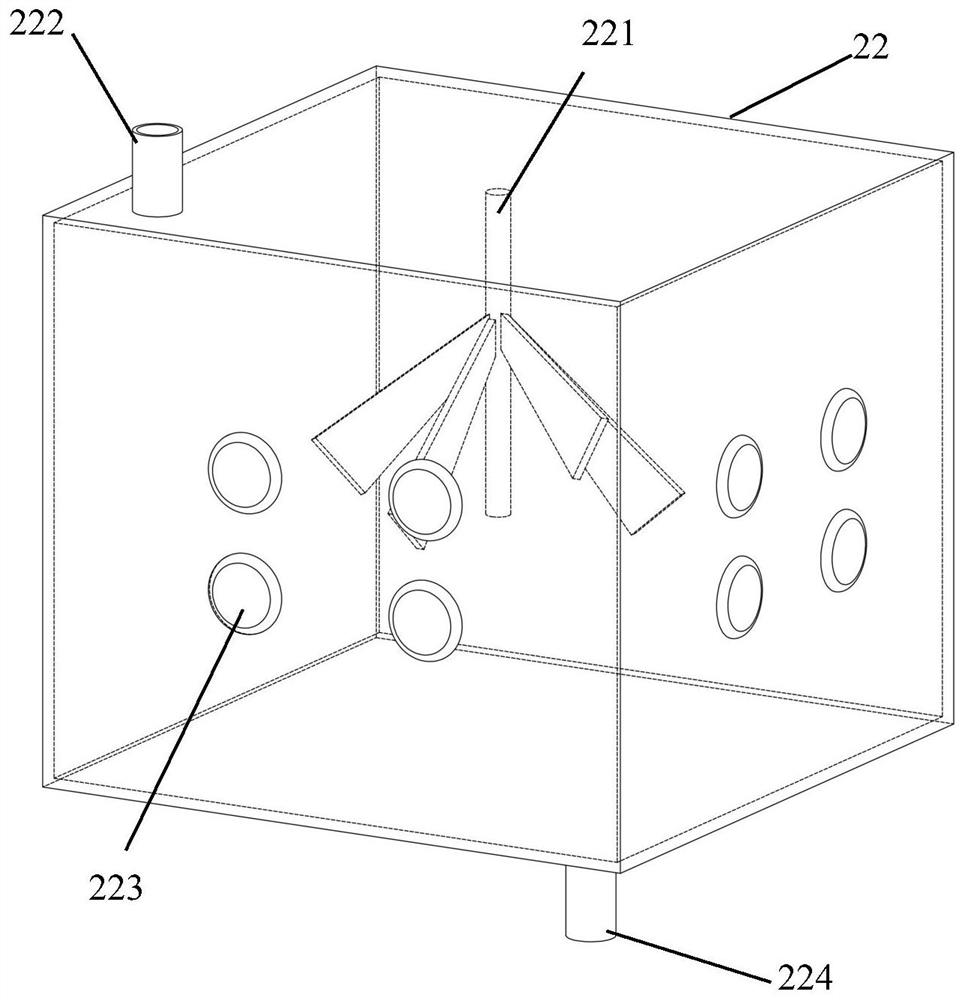

A technology for hemicellulose and extraction equipment, applied in chemical instruments and methods, mixers with rotary stirring devices, transportation and packaging, etc., can solve the problems of waste of resources, low purity of hemicellulose, low extraction efficiency, etc. Achieve the effect of improving extraction rate, rich source and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

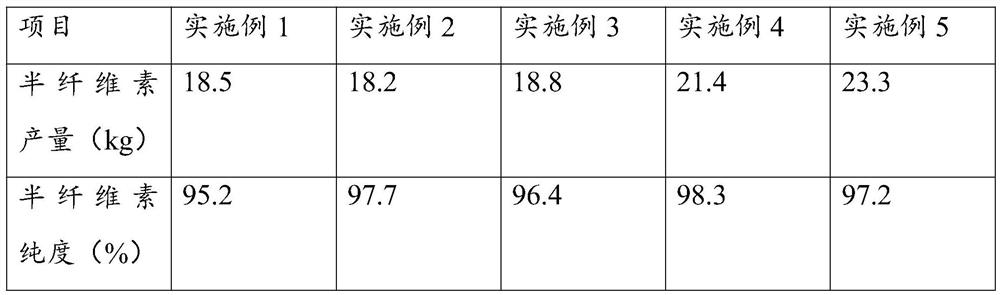

Embodiment 1

[0053] Extraction method for extracting hemicellulose from straw using extraction equipment:

[0054] (1) 50kg of rice straw and 50kg of sugarcane straw are put into a pulverizer for crushing, and the crushed straw is transported to a pretreatment device by a conveyor belt and degreased with n-hexane, then stirred and plate-and-frame filtered to obtain a straw filtrate;

[0055] (2) Transport the stalk filtrate to the mixing reactor at 48°C for 15 hours, and add the mixed solution to the mixing reactor at the same time to react to obtain the reaction solution; the mixed solution is prepared by 2mol / L sodium hydroxide solution and butanol : The mass ratio of 1.1 is mixed to obtain;

[0056] (3) ultrasonically treat the reaction solution at 650W and 950°C for 15 minutes to obtain the ultrasonic treatment solution;

[0057] (4) After condensing and filtering the ultrasonic treatment solution, centrifuge at 5500r / min for 10min, take the supernatant and add absolute ethanol for al...

Embodiment 2

[0059] Extraction method for extracting hemicellulose from straw using extraction equipment:

[0060] (1) 100kg of wheat straw is put into a pulverizer for pulverization, and the pulverized straw is transported to a pretreatment device by a conveyor belt, degreased with n-hexane, then stirred and plate-and-frame filtered to obtain a straw filtrate;

[0061] (2) Transport the straw filtrate to the mixing reactor for 18 hours at 40°C, and add the mixed solution to the mixing reactor at the same time to react to obtain the reaction solution; the mixed solution is composed of 2mol / L sodium hydroxide solution and butanol by 1 : The mass ratio of 0.8 is mixed to obtain;

[0062] (3) ultrasonically treat the reaction solution at 800W and 100°C for 10 minutes to obtain the ultrasonic treatment solution;

[0063] (4) After condensing and filtering the ultrasonic treatment solution, centrifuge at 7000r / min for 5min, take the supernatant and add absolute ethanol for alcohol precipitatio...

Embodiment 3

[0065] Extraction method for extracting hemicellulose from straw using extraction equipment:

[0066] (1) 100 kg of cotton stalks are put into a pulverizer for crushing, and the crushed stalks are transported to a pretreatment device by a conveyor belt and degreased with n-hexane, then stirred and plate-and-frame filtered to obtain a straw filtrate;

[0067] (2) Transport the stalk filtrate to the mixing reactor at 50°C for 10 hours, and add the mixed solution to the mixing reactor at the same time to react to obtain the reaction solution; the mixed solution is composed of 1mol / L sodium hydroxide solution and butanol : The mass ratio of 1.2 is mixed to obtain;

[0068] (3) ultrasonically treat the reaction solution at 600W and 80°C for 20 minutes to obtain the ultrasonic treatment solution;

[0069] (4) After the ultrasonic treatment solution is subjected to condensation filtration, it is centrifuged at 5000r / min for 10 minutes, and the supernatant is added to absolute ethano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com