Synthesis method of water-based asparaginous polyurea and application of water-based asparaginous polyurea in sealant

A synthesis method and water-based technology, applied in the field of synthesis of water-based aspartame polyurea, can solve the problems of difficulty in taking into account adhesion, durability and environmental protection performance, no water erasable function, unfavorable cleaning treatment, etc., and achieve high performance. The effect of abrasion resistance, promotion of improvement, promotion of cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

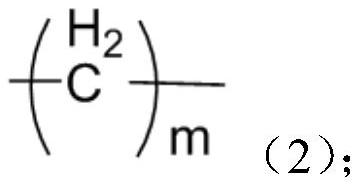

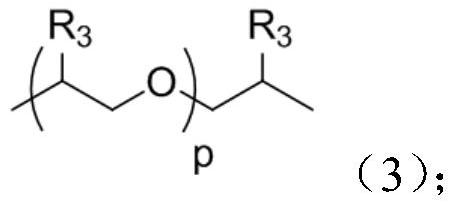

[0042] First aspect of the present invention provides a kind of synthetic method of waterborne aspartame, comprises the following steps:

[0043] Under nitrogen atmosphere, mix aspartic acid ester resin F and diisocyanate, add chain extender and solvent to mix, then add water-based aspartic acid ester resin N, after stirring, add water to emulsify, obtain water-based aspartic polyurea Emulsion; further, under nitrogen atmosphere, mix aspartic acid ester resin F and diisocyanate for 4-8 minutes, add chain extender and solvent and mix for 4-8 minutes, then add water-based aspartic acid ester resin N, stir for 8 minutes ~15 minutes later, add water to emulsify for 4~8 minutes to obtain water-based aspartame emulsion.

[0044]The applicant found that by first adding common aspartic acid ester resin F and diisocyanate, chain extender, etc. to react for a period of time, adding water-based aspartic acid ester resin with sulfonate, the polyurea resin main chain When emulsifying with...

Embodiment 1

[0104] This example provides a kind of synthetic method of water-based aspartame, comprising the following steps:

[0105] (1) Add diethyl maleate dropwise to diamine A, react at 40°C to obtain intermediate M, and the molar ratio of diethyl maleate to diamine A is 1:1;

[0106] (2) Add intermediate M to acetone, and add sodium vinylsulfonate dropwise to react at 40°C to obtain aqueous aspartate resin N;

[0107] (3) Under nitrogen atmosphere, mix aspartic acid ester resin F and diisocyanate for 5 minutes, add chain extender and solvent and mix for 5 minutes, then add water-based aspartic acid ester resin N, stir for 10 minutes, add water to emulsify for 5 minutes , to obtain aqueous aspartic polyurea emulsion; the molar ratio of the aspartic acid ester resin F, aqueous aspartic acid ester resin N, diisocyanate and chain extender is 1:0.1:1.2:1, and the water accounts for 5wt% of aqueous aspart polyurea emulsion.

[0108] The structural formula of the diamine A is as follows:...

Embodiment 2

[0119] This example provides a kind of synthetic method of water-based aspartame, comprising the following steps:

[0120] (1) Add diethyl maleate dropwise to diamine A, react at 40°C to obtain intermediate M, and the molar ratio of diethyl maleate to diamine A is 1:1;

[0121] (2) Add intermediate M to acetone, and dropwise add sodium vinyl sulfonate, and react at 45°C to obtain aqueous aspartate resin N;

[0122] (3) Under nitrogen atmosphere, mix aspartic acid ester resin F and diisocyanate for 5 minutes, add chain extender and solvent and mix for 5 minutes, then add water-based aspartic acid ester resin N, stir for 10 minutes, add water to emulsify for 5 minutes , to obtain aqueous aspartic polyurea emulsion; the molar ratio of the aspartic acid ester resin F, aqueous aspartic acid ester resin N, diisocyanate and chain extender is 1:0.1:1.2:1, and the water accounts for 15 wt% of aqueous aspart polyurea emulsion.

[0123] The structural formula of the diamine A is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com