Liquid crystal polyester, liquid crystal polyester composition and application thereof

A technology of liquid crystal polyester and composition, applied in the field of liquid crystal polyester composition and application, liquid crystal polyester, to achieve the effects of easy crystal growth, efficient directional catalysis, and reduction of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8 and comparative example 1-8

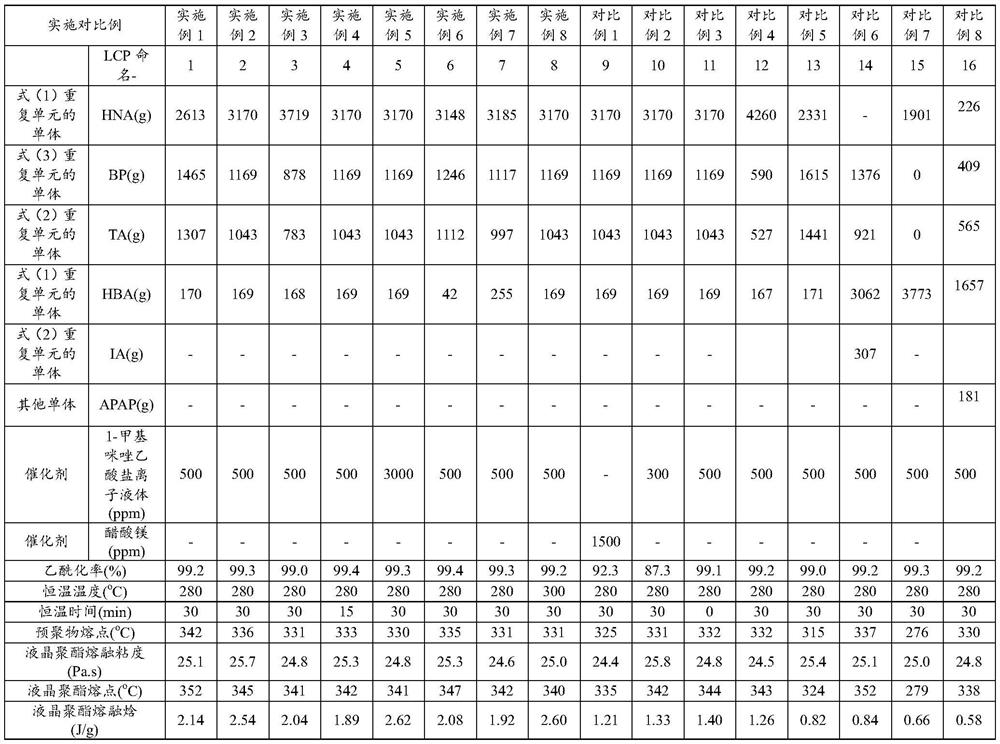

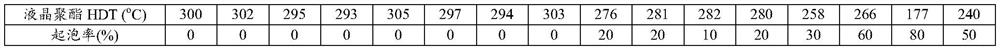

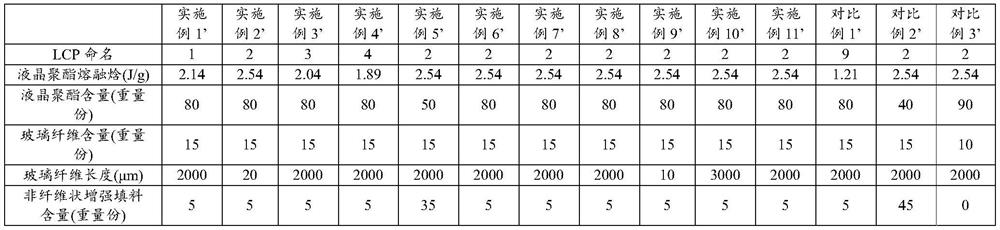

[0084] Examples 1-8 and Comparative Examples 1-8: Liquid crystal polyester

[0085] The raw material composition of the liquid crystal polyester of embodiment 1-8 and comparative example 1-8 is as shown in table 1, and the preparation method of liquid crystal polyester comprises the following steps:

[0086] S1. Acetylation section: add monomer, acetic anhydride and catalyst into the first reaction vessel equipped with agitator, monomer feeding port, reflux condenser, thermometer and nitrogen inlet port, and completely replace with nitrogen after feeding is completed The atmosphere in the reaction vessel, under the protection of nitrogen, the temperature of the reaction system was raised to 140 ° C, and the temperature was maintained at reflux for 2 hours to carry out the acetylation reaction;

[0087] S2. Melting polycondensation section: After the acetylation reaction is completed, the material is transferred to the second reaction vessel equipped with a stirrer equipped wit...

Embodiment 2

[0095] The results of Example 2, Example 4, Example 8 and Comparative Example 3 show that in the melt polycondensation process of liquid crystal polyester, adopting a constant temperature of 280 to 300°C for 15 to 30 minutes is beneficial to improving the melting enthalpy of liquid crystal polyester, thereby increasing the thermal Deformation temperature, and reduce foaming rate.

[0096] The results of embodiment 2, embodiment 5 and comparative example 1-2 can be known, compare comparative example 1 and adopt magnesium acetate as catalyzer, the present invention selects 1-methylimidazole acetate ionic liquid as catalyzer, and acetylation rate is high, It is more beneficial to obtain liquid crystal polyester with high melting enthalpy, high heat distortion temperature and low foaming rate. When the addition amount of the 1-methylimidazolium acetate ionic liquid is more than 500 ppm of the theoretical output weight of the liquid crystal polyester, the effect is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com