High-ammonia-nitrogen wastewater treatment system and process

A wastewater treatment system, high ammonia nitrogen technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc. Problems such as big problems, to achieve good processing results and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

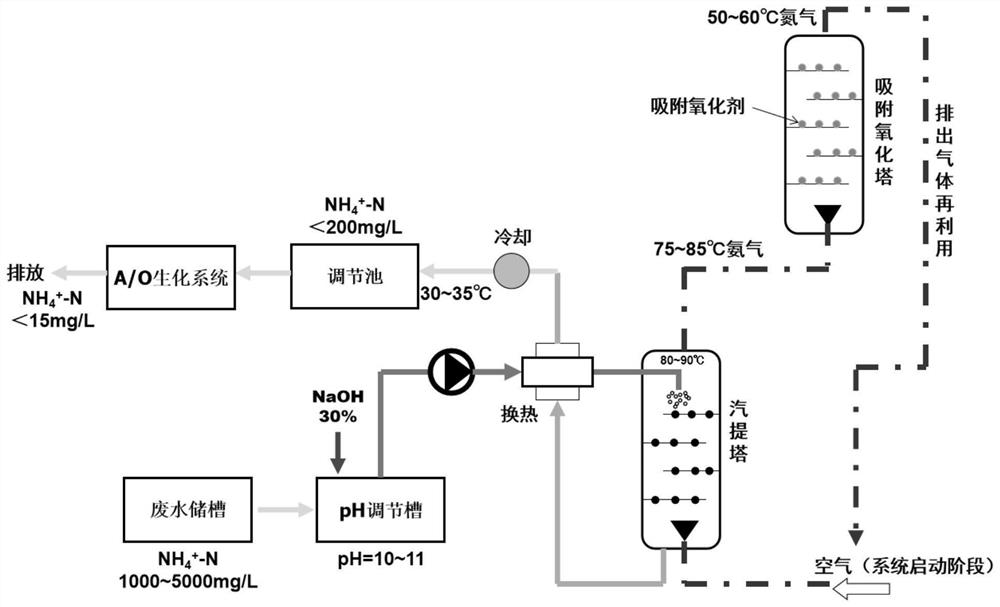

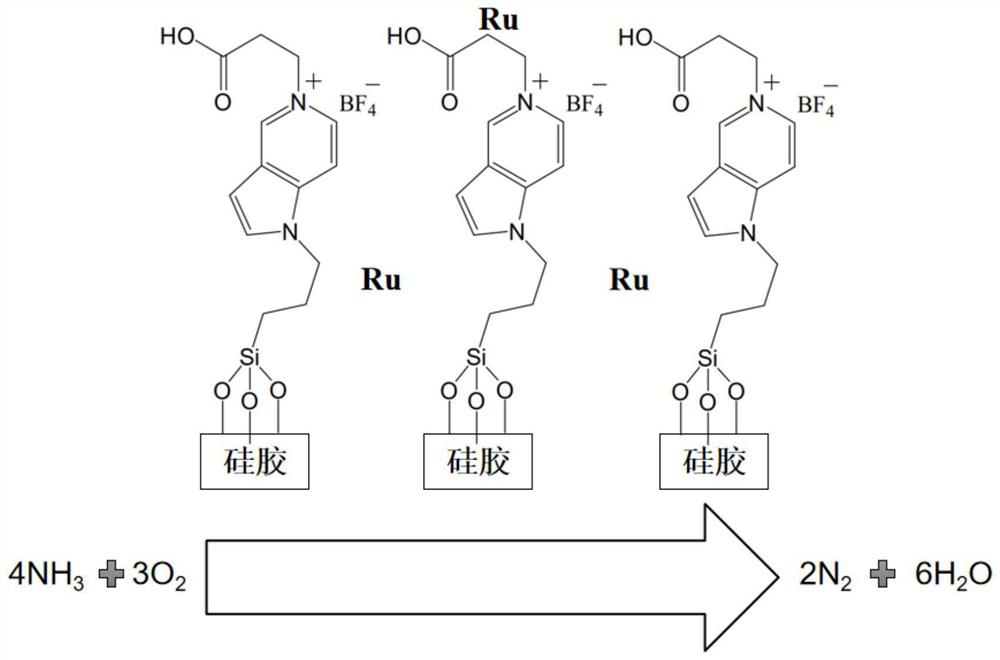

[0105] The present embodiment provides a process for treating high ammonia nitrogen wastewater, comprising the following steps:

[0106] S1, set the flow to 0.2m 3 / h, high ammonia nitrogen wastewater with ammonia nitrogen concentration of 1000mg / L and pH of 9.7 (nitrate nitrogen concentration is about 0mg / L, COD concentration is about 0mg / L, and total nitrogen concentration is 1000mg / L) to the pH adjustment tank, The pH value of wastewater is adjusted to 10-11 by adding NaOH solution with a mass fraction of 30% into the pH adjustment tank through a flow pump;

[0107] S2. The effluent of the pH adjustment tank is transported to the heat exchanger for heat exchange, and then sprayed from the top into the stripper, and is in countercurrent contact with the gas that enters the stripper from the bottom, so that the ammonia in the waste water is converted from liquid phase to gas phase Then it is discharged from the top of the stripper;

[0108] Among them, the gas flow rate ent...

Embodiment 2

[0133] This embodiment adopts the same adsorbed oxidant as in Embodiment 1, and the differences are mainly listed below.

[0134] A process for treating high ammonia nitrogen wastewater provided by this embodiment includes the following steps:

[0135] S1, set the flow to 0.2m 3 / h, high ammonia nitrogen wastewater with ammonia nitrogen concentration of 4000mg / L and pH of 9.96 (nitrate nitrogen concentration is about 0mg / L, COD concentration is about 0mg / L, and total nitrogen concentration is 4000mg / L) to pH adjustment tank, The pH value of wastewater is adjusted to 10-11 by adding NaOH solution with a mass fraction of 30% into the pH adjustment tank through a flow pump;

[0136] S2. The effluent of the pH adjustment tank is transported to the heat exchanger for heat exchange, and then sprayed from the top into the stripper, and is in countercurrent contact with the gas that enters the stripper from the bottom, so that the ammonia in the waste water is converted from liquid p...

Embodiment 3

[0146] This embodiment adopts the same adsorbed oxidant as in Embodiment 1, and the differences are mainly listed below. The present embodiment provides a process for treating high ammonia nitrogen wastewater, comprising the following steps:

[0147] S1, set the flow to 0.2m 3 / h, high ammonia nitrogen wastewater with ammonia nitrogen concentration of 1000mg / L and pH of 9.7 (nitrate nitrogen concentration is about 0mg / L, COD concentration is about 0mg / L, and total nitrogen concentration is 1000mg / L) to the pH adjustment tank, The pH value of wastewater is adjusted to 10-11 by adding NaOH solution with a mass fraction of 30% into the pH adjustment tank through a flow pump;

[0148] S2. The effluent of the pH adjustment tank is transported to the heat exchanger for heat exchange, and then sprayed from the top into the stripper, and is in countercurrent contact with the gas that enters the stripper from the bottom, so that the ammonia in the waste water is converted from liquid ...

PUM

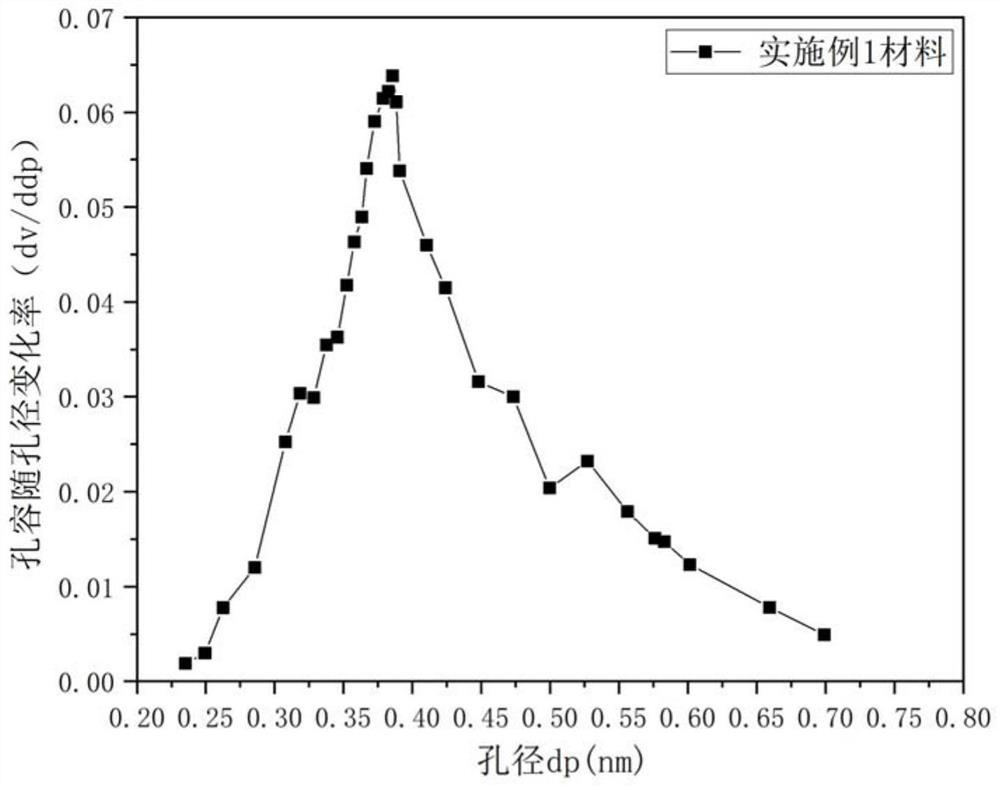

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com