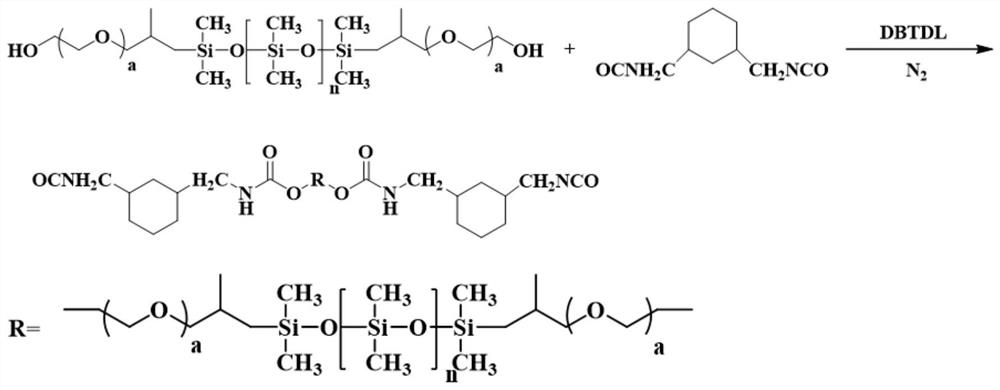

Preparation method of isocyanate polyether modified silicone oil finishing agent

A technology of polyether modification and isocyanate, which is applied in fiber treatment, textiles and papermaking, and fibers that affect crease behavior. It can solve the problems of different effects, anti-wrinkle effect needs to be further improved, and easy mutual restraint, etc., to achieve low cost, The effect of increasing wrinkle recovery angle and reducing strong damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Add 0.25mol cyclohexane-1,3 diisocyanate to a four-necked flask equipped with a thermometer, condenser, and magnetic stirrer, add 15mL dioxane to it, and stir and heat up under nitrogen protection conditions to 50°C, slowly add 0.125 molHPEG modified hydroxyalkyl polysiloxane dropwise, after the addition, raise the temperature to 70°C, add 3 drops of stannous octoate as a catalyst, and react for 3 hours to obtain isocyanate polyether modified polysiloxane pre- Polymer.

[0055] (2) Lower the isocyanate polyether-modified polysiloxane prepolymer prepared in step (1) to 20-30° C., add 0.1 mol of ethylene glycol, and continue to heat up to 90° C. to react for 4 hours to obtain the final product. Cool to room temperature, add water to disperse under vigorous stirring to obtain isocyanate-modified polysiloxane, which is light yellow transparent viscous liquid. The end-capping rate was calculated by referring to the method for calculating the end-capping rate above, and ...

Embodiment 2

[0059] Same as the preparation method in Example 1, the only difference is that the catalyst stannous octoate is replaced with dibutyltin dilaurate, all the other methods and consumption are constant, and the end-capping rate is calculated with reference to the method for calculating the end-capping rate above, The calculation results are shown in Table 1.

Embodiment 3

[0061] The same as the preparation method in Example 1, the only difference is that the catalyst stannous octoate is replaced by triethylenediamine, the rest of the methods and dosage remain unchanged, the end-capping rate is calculated with reference to the method for calculating the end-capping rate above, and the calculation results See Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com