Plastic functional modified master batch and preparation method thereof

A technology of modifying masterbatch and function, applied in the direction of coating, etc., can solve the problems affecting the processing effect of finished products, masterbatch desquamation, grinding, poor structural strength, etc., to improve wear resistance and transportation safety, Masterbatch has good performance and the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

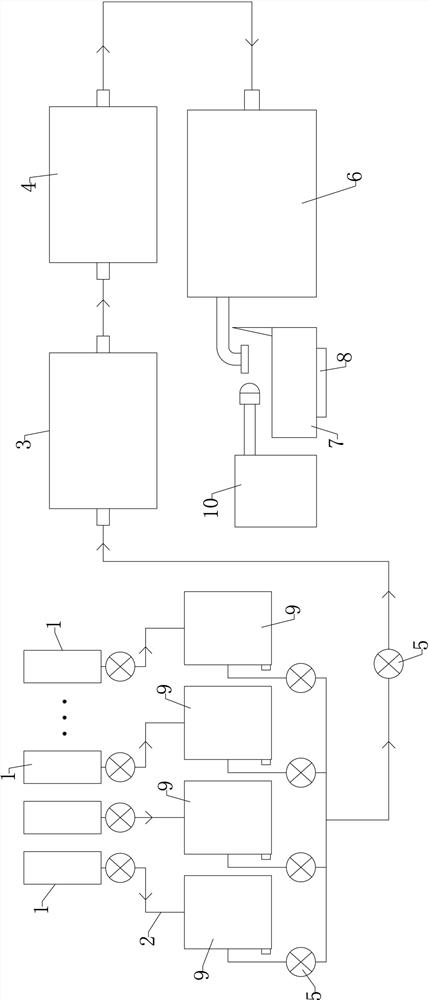

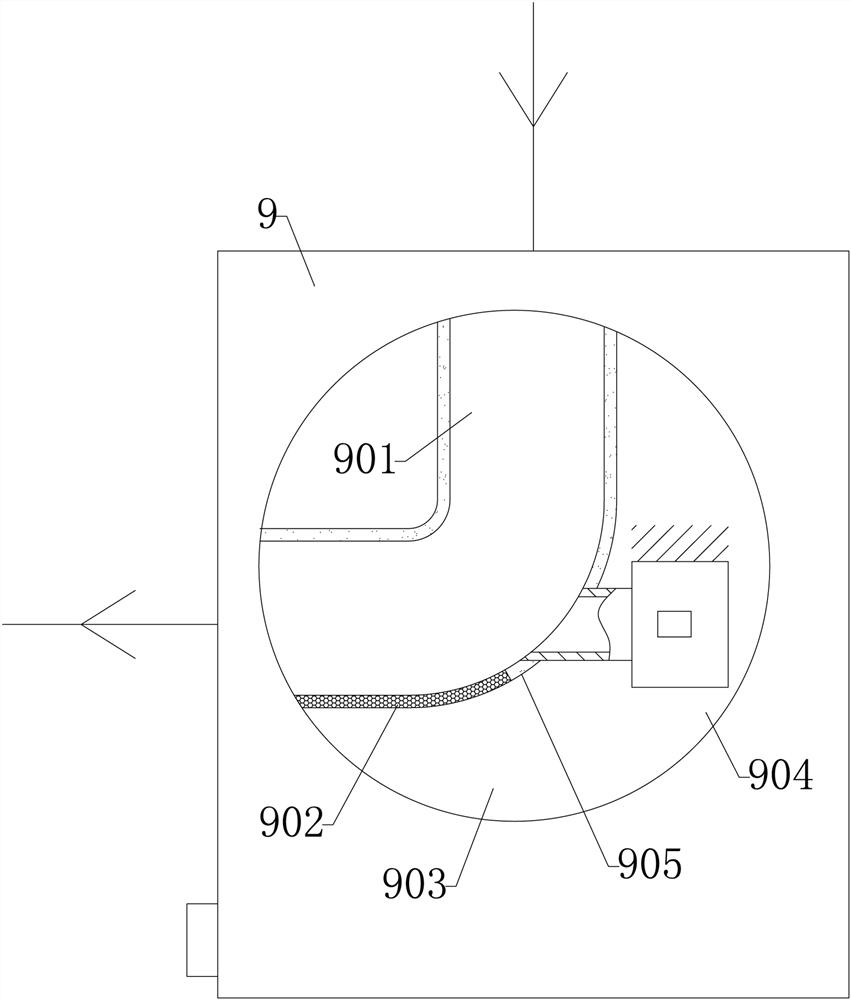

Method used

Image

Examples

Embodiment 1

[0031] Plastic functional modified masterbatch, including the following components in parts by weight: 100 parts of polypropylene resin, 100 parts of polybutylene succinate, 30 parts of organotin, 10 parts of compatibilizer, 2 parts of plastic additives, anti- 2 parts of oxidizing agent.

[0032] Modification is achieved by setting plastic additives to improve the toughness of the masterbatch.

[0033] Preferably, the following components are also included in parts by weight: 30 parts of nano-silicon dioxide, 30 parts of nano-titanium dioxide, and 10 parts of crosslinking agent.

[0034] The preparation method of plastic functional modified masterbatch is characterized in that: comprising the following steps:

[0035] Add 100 parts of polypropylene resin, 100 parts of polybutylene succinate, 10 parts of compatibilizer, 2 parts of plastic additives, and 2 parts of antioxidant, and put the above-mentioned materials into the plastic according to the category and the above-mentio...

Embodiment 2

[0059] Embodiment 2: the difference with embodiment is:

[0060] Plastic functional modification masterbatch, including the following components in parts by weight: 300 parts of polypropylene resin, 300 parts of polybutylene succinate, 50 parts of organotin, 20 parts of compatibilizer, 5 parts of plastic additives, anti- 5 parts of oxidizing agent.

[0061] Preferably, the following components are also included in parts by weight: 50 parts of nano silicon dioxide, 50 parts of nano titanium dioxide, and 20 parts of crosslinking agent.

[0062] The preparation method of plastic functional modified masterbatch is characterized in that it comprises the following steps: adding 300 parts of polypropylene resin, 300 parts of polybutylene succinate, 20 parts of compatibilizer, 5 parts of plastic additives, 5 parts of antioxidant Parts, the above-mentioned materials are separately put into the plastic functional modified masterbatch preparation system according to the category and the...

Embodiment 3

[0068] Embodiment 3: the difference with embodiment 2 is:

[0069] Plastic functional modification master batch, including the following components in parts by weight: 200 parts of polypropylene resin, 200 parts of polybutylene succinate, 40 parts of organotin, 15 parts of compatibilizer, 3 parts of plastic additives, anti 3 parts of oxidizing agent.

[0070] Preferably, the following components are also included in parts by weight: 40 parts of nano-silicon dioxide, 40 parts of nano-titanium dioxide, and 15 parts of crosslinking agent.

[0071] The preparation method of plastic functional modified masterbatch is characterized in that it comprises the following steps: adding 200 parts of polypropylene resin, 200 parts of polybutylene succinate, 15 parts of compatibilizer, 3 parts of plastic additives, 3 parts of antioxidant Parts, the above-mentioned materials are separately put into the plastic functional modified masterbatch preparation system according to the category and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com