Method for preparing carbon monoxide through carbon dioxide electrochemical reduction

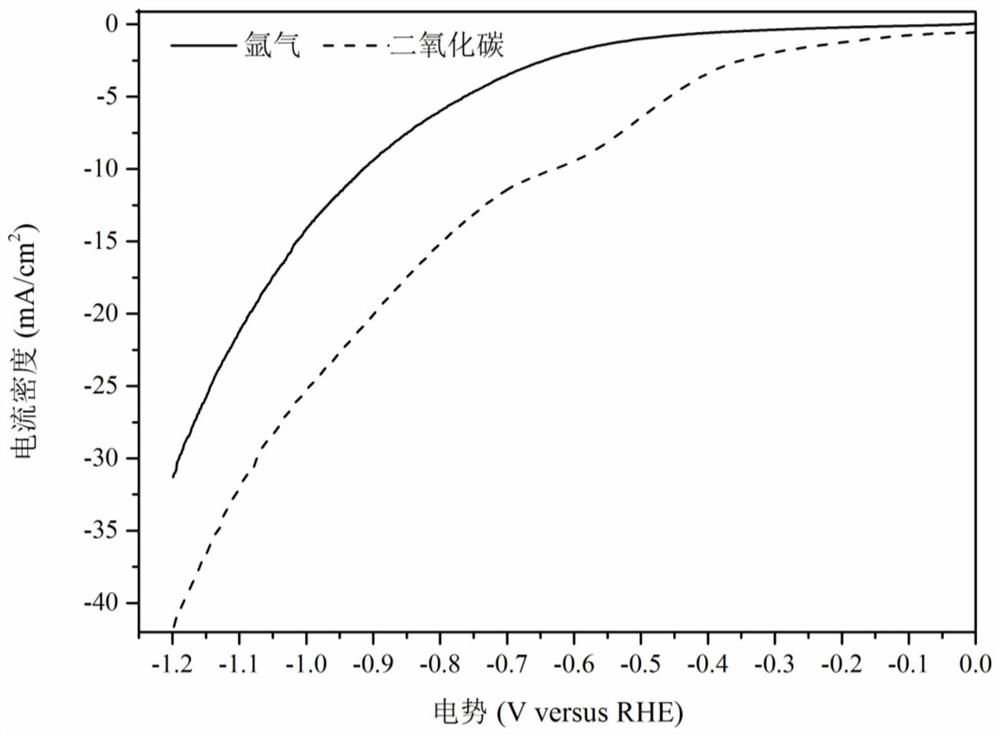

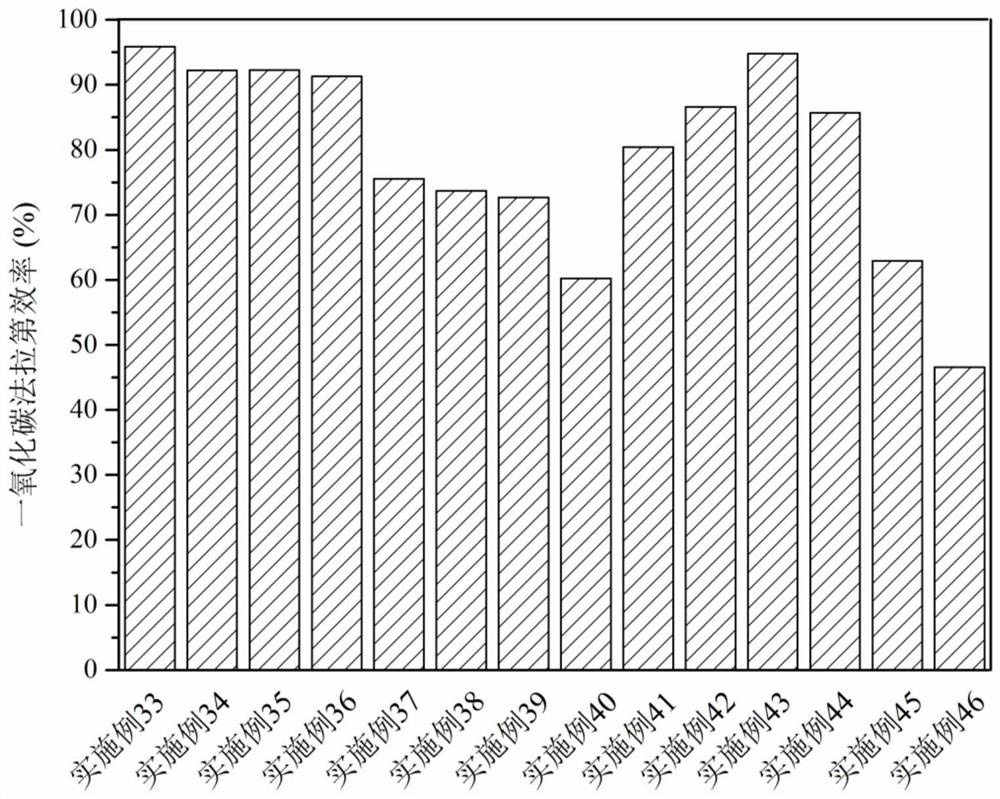

A carbon dioxide and carbon monoxide technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problem of scarcity of catalytic materials, and achieve the effect of inhibiting hydrogen evolution reaction, improving Faradaic efficiency, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: catalyst preparation

[0043] Preparation concentration is that the sodium borohydride solution of 0.075%, the trisodium citrate solution that concentration is 1%, the chloroauric acid solution that concentration is 10% and the silver nitrate solution that concentration is 10%, place 100mg multi-walled carbon nanotubes in Put in a beaker containing 50mL deionized water and ultrasonically disperse for 30min, measure 150mL deionized water and add it to a 500mL round bottom flask, add 1mL chloroauric acid solution and 1mL silver nitrate solution, add 2mL trisodium citrate solution and 2mL Sodium borohydride solution, finally add multi-walled carbon nanotubes after ultrasonic dispersion, stir evenly in ice-water bath for 2h, the stirring rate is 500rpm, after centrifugation, washing, vacuum drying, the gold-silver bimetallic catalyst supported by multi-walled carbon nanotubes is obtained , which is the electrochemical reduction catalyst of carbon dioxide, call...

Embodiment 2

[0044] Embodiment 2: catalyst preparation

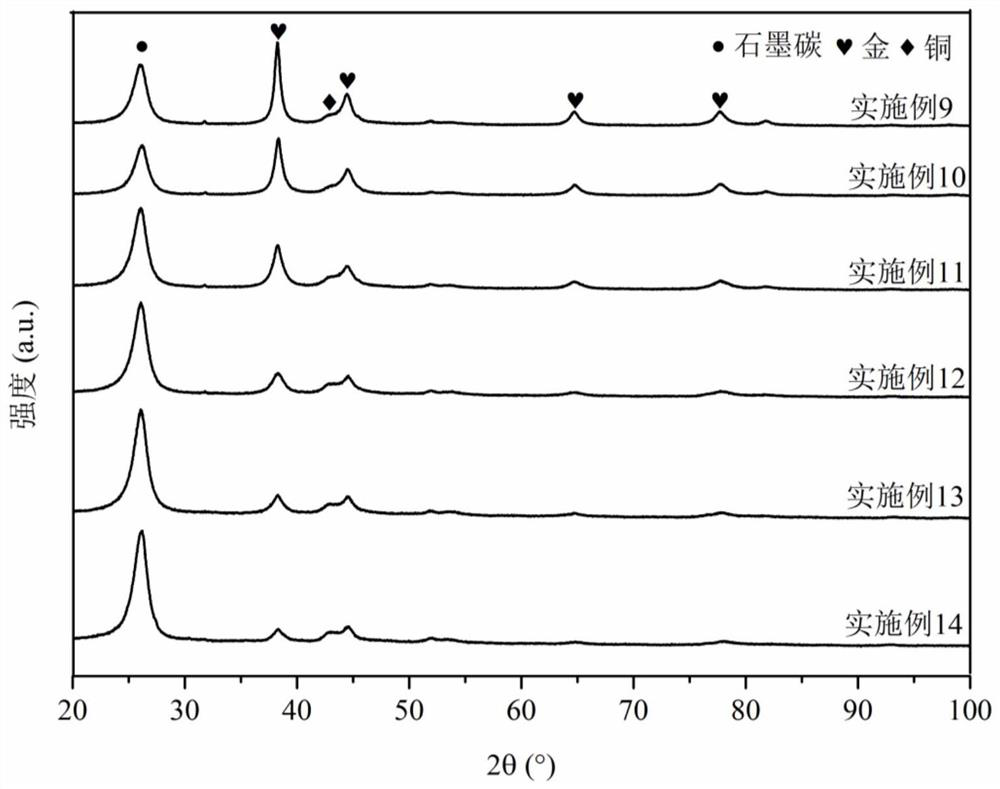

[0045] The specific preparation process is as shown in Example 1, only changing the type of the precursor solution of the second metal, adding 1 mL of copper acetylacetonate solution with a concentration of 10%, can obtain the gold-copper bimetallic catalyst supported by multi-walled carbon nanotubes , called AuCu / CNTs catalyst.

Embodiment 3

[0046] Embodiment 3: catalyst preparation

[0047] The specific preparation process is as shown in Example 1, only changing the type of the precursor solution of the second metal, adding 1 mL of nickel chloride solution with a concentration of 10%, can obtain the gold-nickel bimetallic catalyst supported by multi-walled carbon nanotubes , called AuNi / CNTs catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com