Preparation method and application of polyionic liquid functionalized cobalt-nitrogen loaded foamed nickel composite material

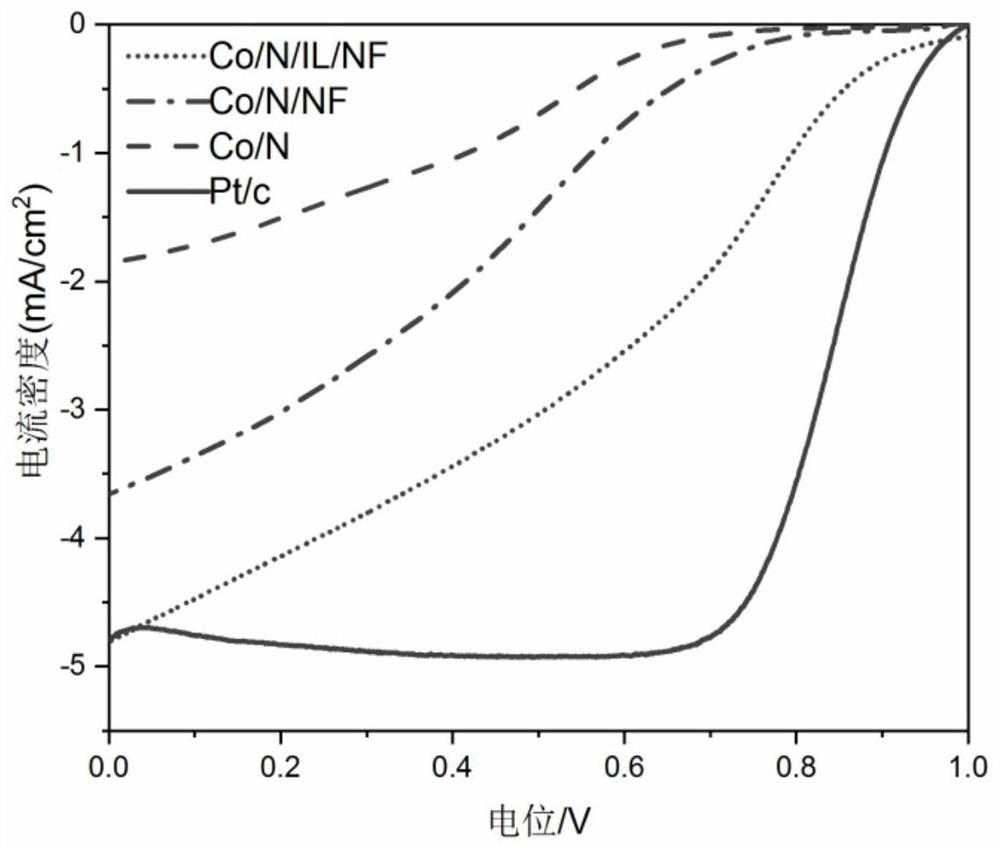

A technology of polyionic liquids and composite materials, which is applied in the preparation of foamed nickel composite materials and the application field of oxygen reduction reaction, which can solve the problems of affecting catalytic activity and reducing electrode conductivity, so as to reduce charge transfer resistance and increase electron transfer rate, the effect of increasing catalytically active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Synthesis of polyionic liquid (Explanation: The molar ratio of 1,5-dichloro-2,4-dinitrobenzene to 2-methylimidazole is 1:1.2)

[0032] Put 0.01 mole of 1,5-dichloro-2,4-dinitrobenzene and 0.012 mole of 2-methylimidazole into a three-necked flask, then add 10ml of absolute ethanol to dissolve it; 2 Heated in an oil bath at 85°C for 48 hours under the protection of the atmosphere, and kept condensing and refluxing; the solid product was separated after the reaction was completed, and the solid product was separated by adding anhydrous ethanol and deionized water for 3 times, respectively, and the solid product was separated again; The polyionic liquid poly[Dbz-mim]cl can be obtained by putting it into a vacuum oven and drying at 55°C for 24 hours.

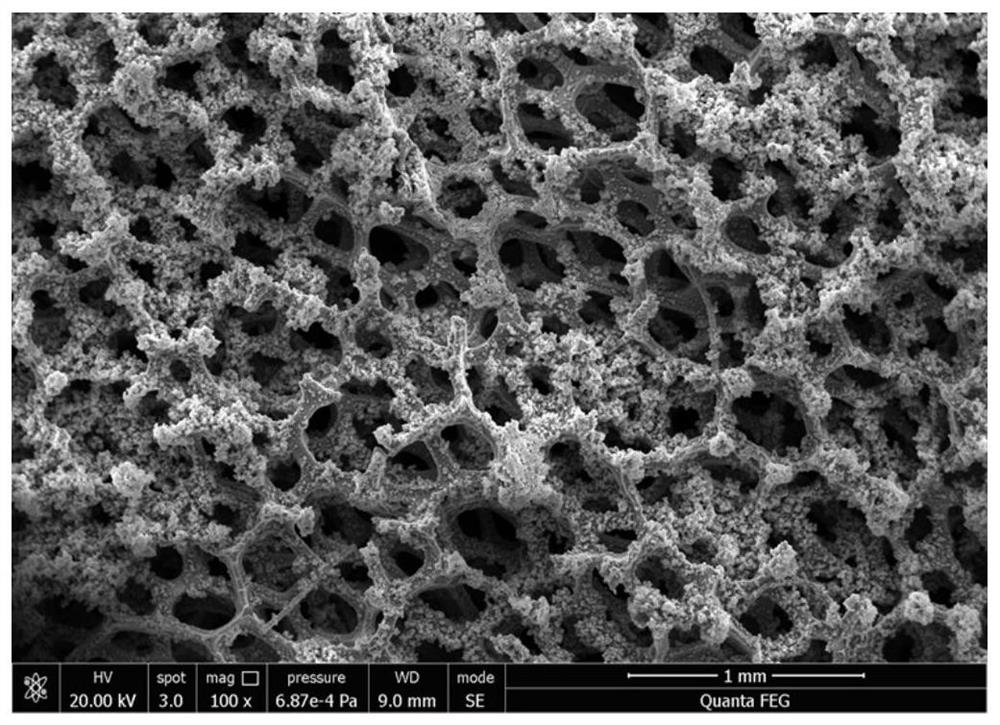

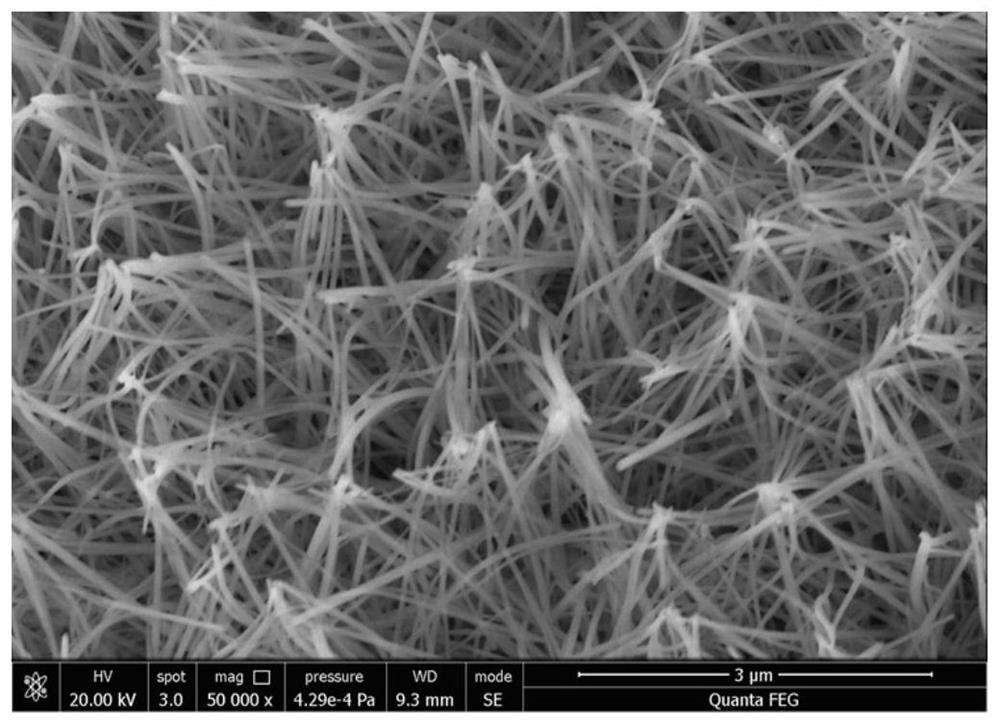

[0033] 2. Preparation of Foamed Nickel Composites

[0034] Cut the nickel foam into a square shape of 1cmx1cm size and wait for treatment; dilute the acetic acid in the laboratory to 3mol / L, so that the nickel foam is ultr...

Embodiment 2

[0036] 1. Synthesis of Polyionic Liquids

[0037] Put 0.02 mole of 1,5-dichloro-2,4-dinitrobenzene and 0.024 mole of 2-methylimidazole into a three-necked flask, then add 20ml of absolute ethanol to dissolve it; 2 Heated in an oil bath at 85°C for 48 hours under the protection of the atmosphere, and kept condensing and refluxing; the solid product was separated after the reaction was completed, and the solid product was separated by adding anhydrous ethanol and deionized water for 3 times, respectively, and the solid product was separated again; Put it into a vacuum oven and dry at 55° C. for 24 hours to prepare the polyionic liquid.

[0038] 2. Preparation of Foamed Nickel Composites

[0039] Cut the nickel foam into a square shape of 1cmx1cm size and wait for treatment; dilute the acetic acid in the laboratory to 3mol / L, so that the nickel foam is ultrasonically treated with acetic acid, absolute ethanol, and deionized water (all volumes are 20ml) for 10 minutes to remove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com