Preparation method of secondary battery and secondary battery

A technology for secondary batteries and battery casings, which is used in the manufacture of electrolyte batteries, lithium batteries, battery pack components, etc. Time, increase the contact area, and solve the effect of difficult suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a secondary battery, comprising the steps of:

[0036] Mix the positive electrode material, conductive agent and positive electrode binder to make a slurry, and coat it on the positive electrode current collector, dry, and roll to obtain the positive electrode sheet; the positive electrode material can be nickel-cobalt-manganese ternary material, lithium cobaltate material, lithium iron phosphate material, lithium-rich manganese-based material, sulfur-carbon composite material, lithium manganate material, lithium nickel manganate material, nickel-cobalt aluminum manganate material; the conductive agent is carbon black (SP ); the binder can be polyvinylidene fluoride (PVDF); specifically, if the positive electrode material is a nickel-cobalt-manganese ternary material, the compaction density of the positive electrode sheet is greater than or equal to 3.6; if the positive electrode material is phosphoric acid Lithium iron material, the positive elec...

Embodiment 2

[0046] Different from Example 1, a method for preparing a secondary battery comprises the following steps:

[0047] Put the battery cell in the battery case and bake it; the baking method is to bake the battery cell by contacting the battery case, and the contact baking method can not only heat up quickly, but also ensure that each cell The cells are evenly heated and the baking effect is consistent, which is beneficial to the subsequent liquid injection process;

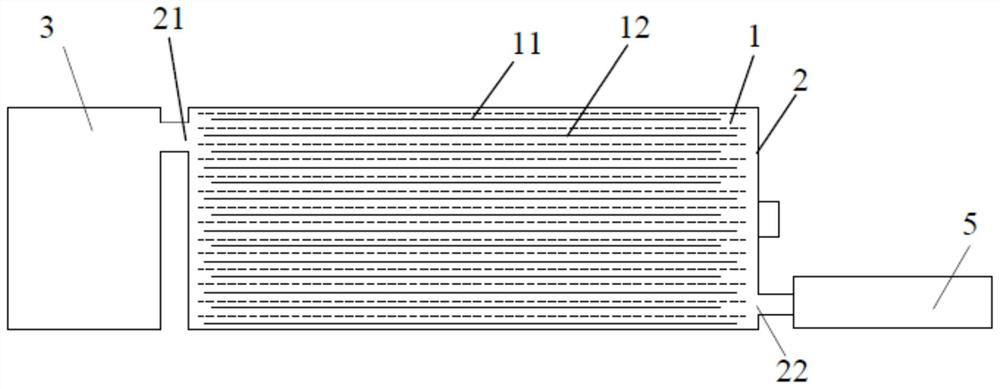

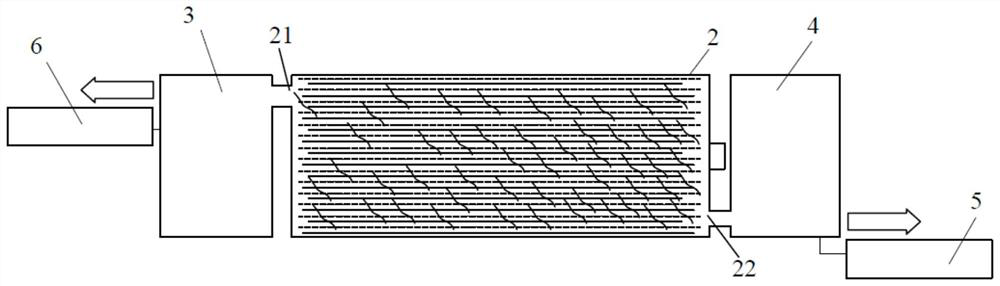

[0048] After the baking is completed, inject the electrolyte solution into the battery case; wherein, the two ends corresponding to the battery case are respectively provided with a first liquid injection port and a second liquid injection port, and the first liquid injection port is stored with the first electrolyte solution. The second liquid injection port is connected to the first vacuum port; the first vacuum port continuously pumps the electrolyte in the first electrolyte storage end from the first liquid inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com