Transition metal molybdotungstate material

A transition metal and molybdenum tungstate technology, applied in metal/metal oxide/metal hydroxide catalysts, molybdenum compounds, tungsten compounds, etc., can solve problems such as doubts about the quality of material structure evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

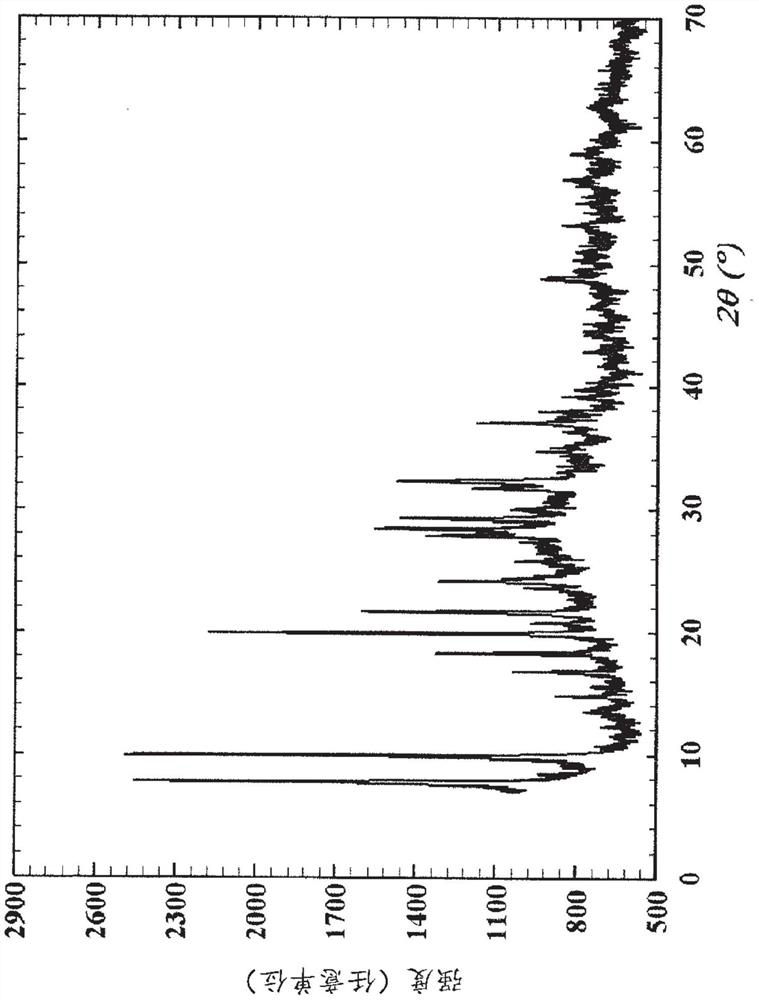

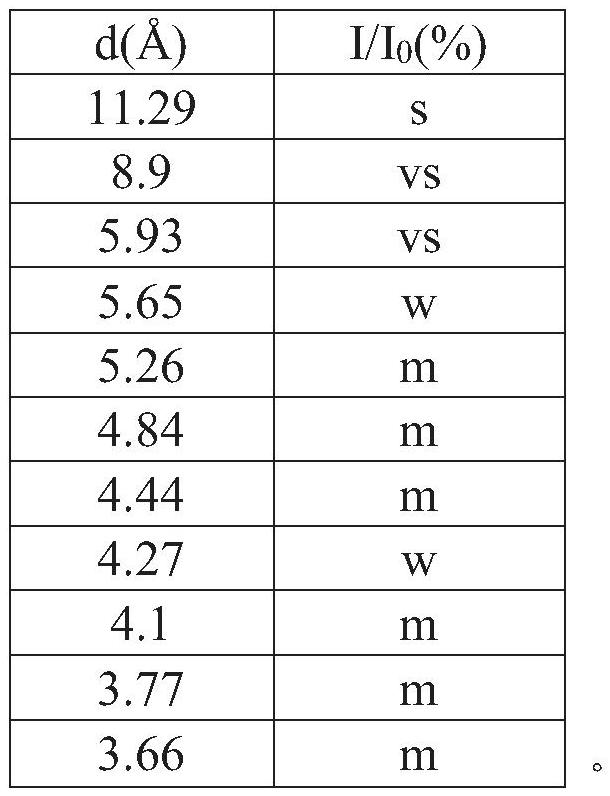

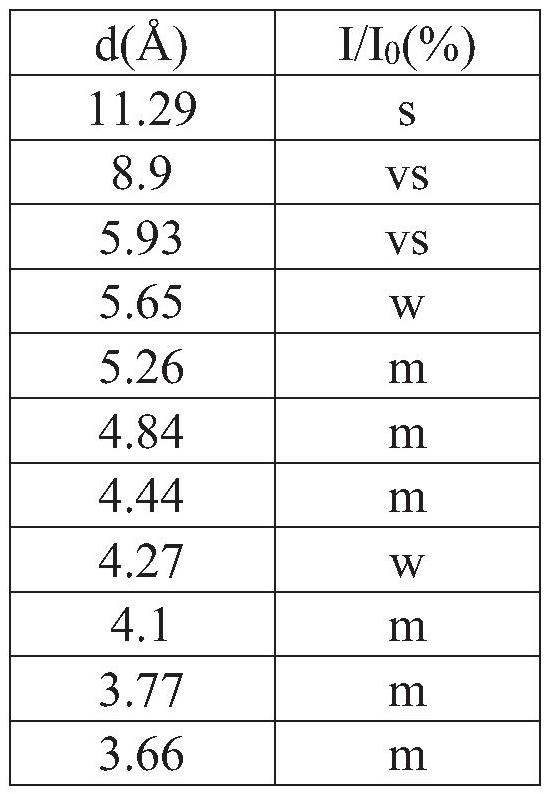

[0058] Nickel nitrate hexahydrate (29.1 g, 0.1 mole of Ni), molybdenum trioxide (2.88 g, 0.02 mole of Mo), ammonium metatungstate hydrate (25.3 g, 0.1 mole of W) and urea (7.5 g, 0.125 mol) in DI H 2 O (5 g) was mixed well and heat treated at 65°C in a sealed PTFE bottle for 24 hours. The resulting mixture was then transferred to a ceramic crucible and heat-treated at 100 °C for an additional 16 hours. The resulting product was analyzed by X-ray powder diffraction, and the X-ray powder diffraction pattern is shown in the accompanying drawing.

Embodiment 2

[0060] Nickel nitrate hexahydrate (29 g, 0.1 moles of Ni), ammonium heptamolybdate (7.06 g, 0.04 moles of Mo) and ammonium metatungstate hydrate (17.71 g, 0.07 moles of W) and ammonium heptamolybdate tetrahydrate (1.76 g, 0.01 mole of Mo) and ammonium carbonate (8.3 g, 0.17 mole of NH 3 ) were mixed together thoroughly and added to a PTFE-lined stainless steel digestion vessel. The mixture was kept at 65°C for 7 days. Thereafter, the green slurry was transferred to a ceramic dish and further heated at 100° C. for a period of 48 hours with intermittent mixing. The resulting product was analyzed by X-ray powder diffraction, and the X-ray powder diffraction pattern is shown in the accompanying drawing.

Embodiment 3

[0062] Nickel nitrate hexahydrate (29.75 g, 0.1 mole of Ni), ammonium heptamolybdate (3.52 g, 0.02 mole of Mo), and ammonium metatungstate hydrate (17.71 g, 0.07 mole of W) and urea (10 g, 0.167 Mole) and DI H 2 O (5 g, 0.278 mol) was mixed together in a sealed PTFE bottle. The mixture was heat treated at 65°C with batch mixing for 30 hours, then transferred to a ceramic dish and heat treated at 200°C. The resulting product was analyzed by X-ray powder diffraction, and the X-ray powder diffraction pattern is shown in the accompanying drawing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com