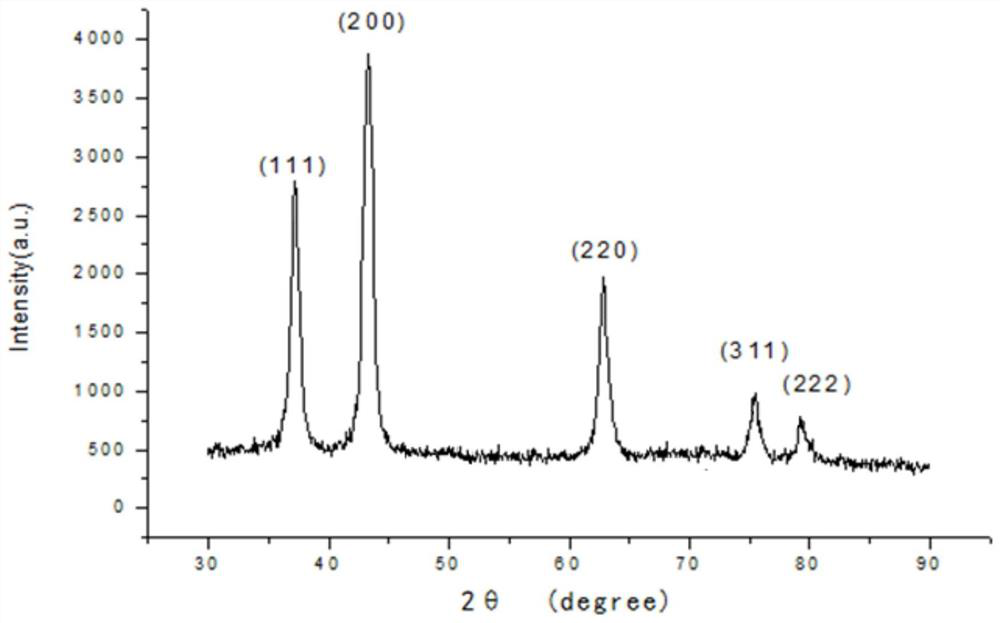

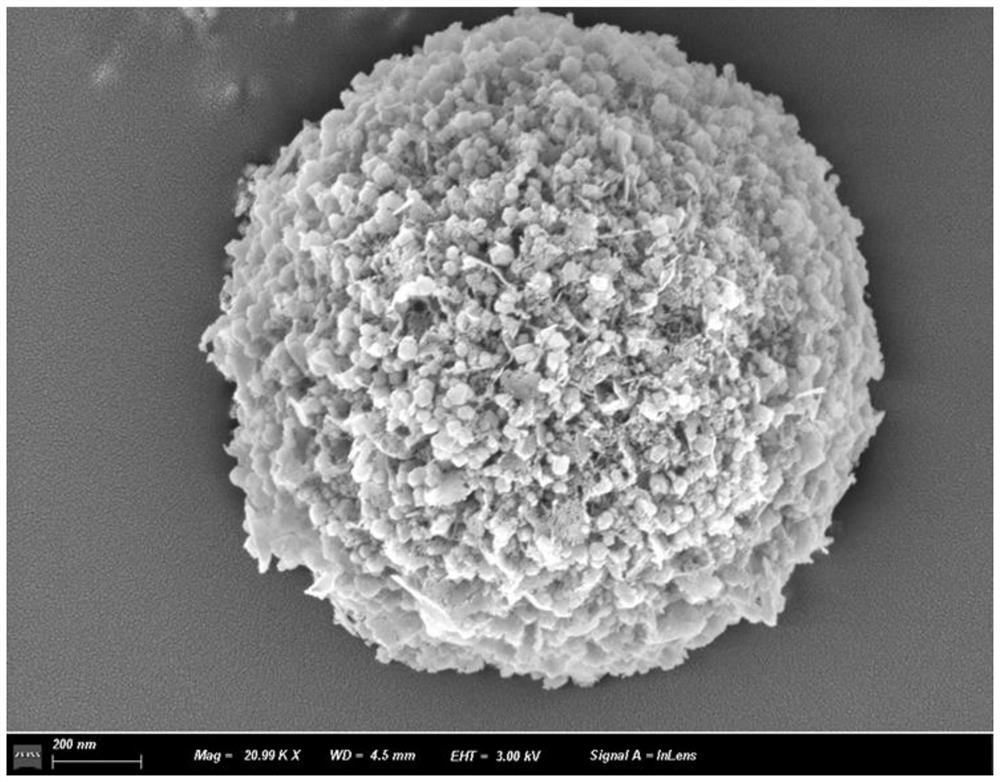

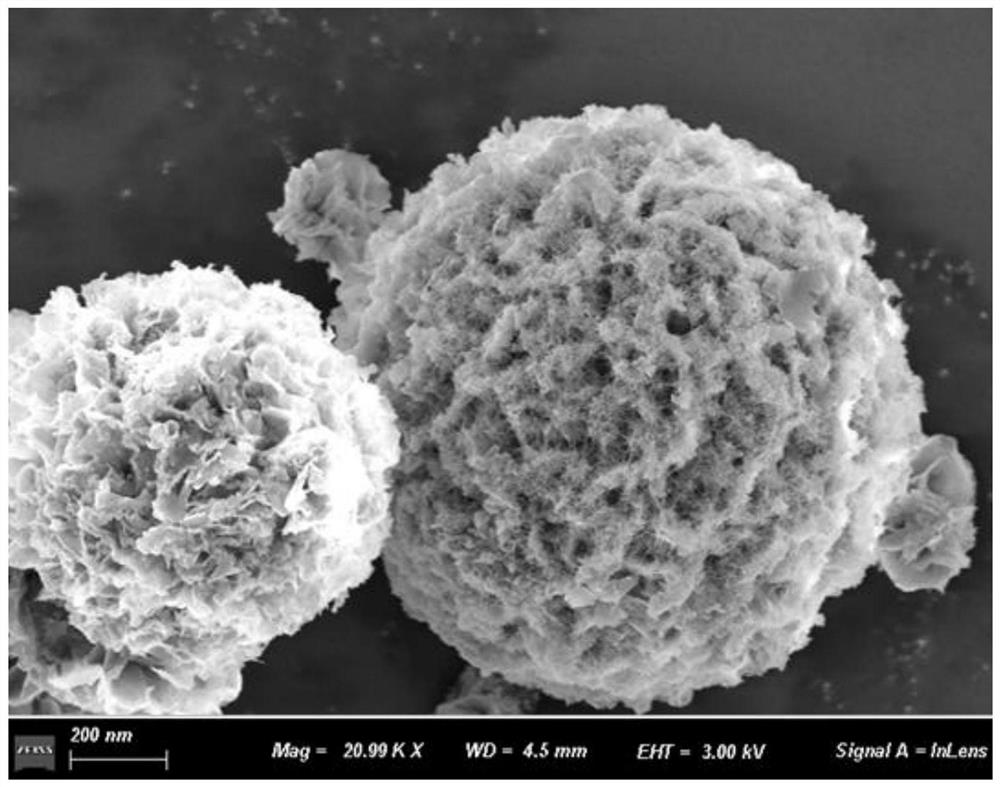

Preparation method of honeycomb-shaped nickel oxide

A nickel oxide, morphology technology, applied in nickel oxide/nickel hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the degradation of photoelectric performance of nickel oxide, the inability to stabilize honeycomb structure, and the collapse of morphology and other problems, to achieve the effect of inhibiting clogging, stable structure and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of nickel oxide with honeycomb morphology, carried out as follows:

[0038] (1), nickel acetate tetrahydrate: urea: SDS = 2:10:1 molar ratio mixture is dissolved in deionized water to form a mixed solution, the mass volume ratio of the mixture and deionized water is 0.2772g / mL;

[0039] (2), add deionized water to the mixed solution while stirring at a speed of 350rpm, the supplemented deionized water is 15 times that of the deionized water in the original mixed solution, then continue to add 1,2-propylene glycol while stirring, and then Continue to stir for 30 minutes to form a precursor solution. The volume ratio of deionized water and 1,2-propanediol in the obtained precursor solution is 1:2;

[0040] (3) Put the precursor solution in the reaction kettle, seal and heat at 190°C for 8 hours, then cool down to room temperature at a rate of 2°C / min;

[0041] (4) Centrifuge after cooling, wash with ethanol and deionized water in sequence, and dry at...

Embodiment 2

[0044] A preparation method of nickel oxide with honeycomb morphology, carried out as follows:

[0045](1), nickel acetate tetrahydrate: urea: SDS = 2:8:1 molar ratio mixture is dissolved in deionized water to form a mixed solution, the mass volume ratio of the mixture and deionized water is 0.2532g / mL;

[0046] (2), add deionized water to the mixed solution while stirring at a speed of 300rpm, the replenished deionized water is 5 times that of the deionized water in the mixed solution, then continue to add 1,2-propylene glycol while stirring, and then Continue to stir for 20 minutes to form a precursor solution, the volume ratio of deionized water and 1,2-propanediol in the obtained precursor solution is 1:4;

[0047] (3) Put the precursor solution in the reaction kettle, seal and heat at 170°C for 14h, then cool down to room temperature at a rate of 2°C / min;

[0048] (4) Centrifuge after cooling, wash with ethanol and deionized water in sequence, and dry at 70°C for 8 hours...

Embodiment 3

[0051] A preparation method of nickel oxide with honeycomb morphology, carried out as follows:

[0052] (1), nickel acetate tetrahydrate: urea: SDS = 2:9:1 molar ratio mixture is dissolved in deionized water to form a mixed solution, the mass volume ratio of the mixture and deionized water is 0.2652g / mL;

[0053] (2), add deionized water to the mixed solution while stirring at a speed of 320rpm, the supplemented deionized water is 10 times that of the deionized water in the mixed solution, then continue to add 1,2-propylene glycol while stirring, and then Continue to stir for 25 minutes to form a precursor solution. The volume ratio of deionized water and 1,2-propanediol in the obtained precursor solution is 1:3.5;

[0054] (3) Put the precursor solution in the reaction kettle, seal and heat at 180°C for 10h;

[0055] (4) Centrifuge after cooling, wash with ethanol and deionized water in sequence, and dry at 75°C for 8 hours;

[0056] (5) The dried precursor was calcined at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com