Device and method for preparing mineral wool fibers

A mineral wool fiber and mineral wool technology, applied in the field of mineral wool fiber preparation, can solve problems such as affecting the quality of the fiber, burns by operators, and difficulty in flowing, and achieve the effects of ensuring fiber quality, ensuring safety, and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of mineral wool raw materials: using analytical reagents to prepare basic mineral wool raw materials, in which the content of CaO in the basic mineral wool raw materials is 35.47%, SiO 2 The content is 44.62%, Al 2 o 3 The content is 12.03%, the MgO content is 7.88%, and the acidity coefficient is 1.31;

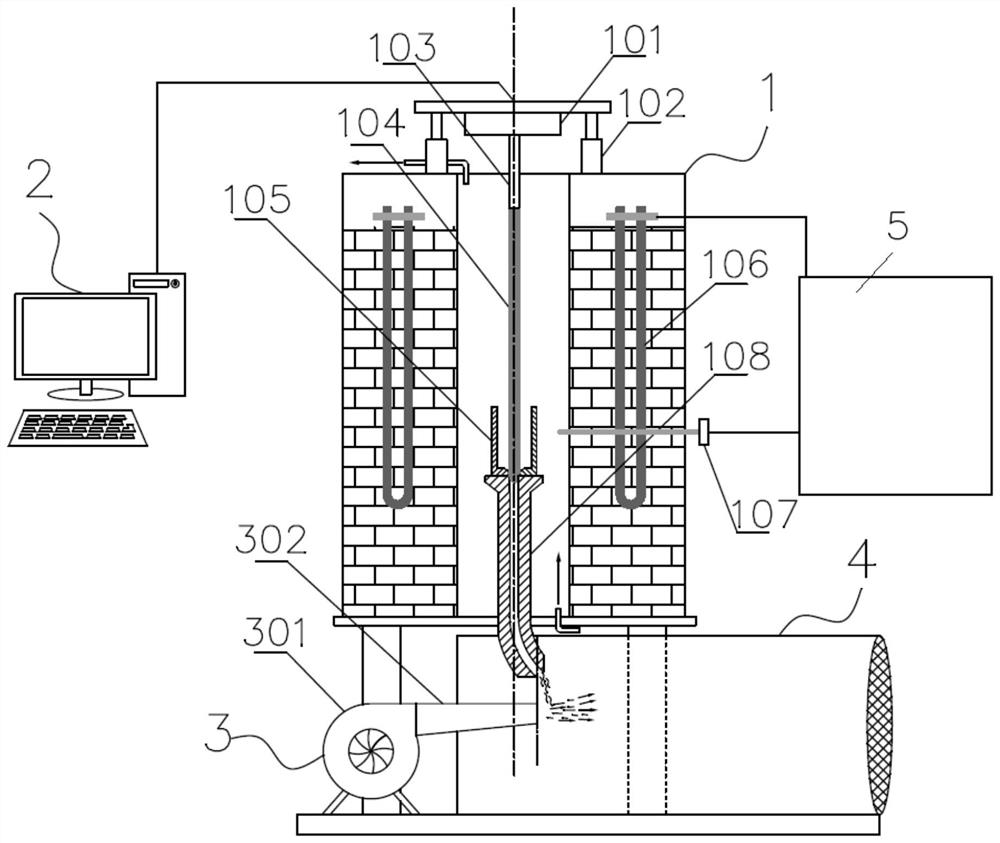

[0033] Blowing to form fibers: Control the computer to control the lifting device to descend, so that the stopper rod and the bottom outlet of the crucible are tightly closed; the prepared mineral wool raw materials are put into the crucible, and the high-temperature resistance furnace operates at a temperature of 15°C / min. Turn on the air compressor immediately after the heating rate reaches 1500°C. When the outlet pressure of the high-pressure nozzle reaches 0.35Mpa and the temperature in the high-temperature resistance furnace is kept at 1500°C for 20 minutes, the lifting device is controlled to rise, and the stopper rod and the material crucible are di...

Embodiment 2

[0036] Preparation of mineral wool raw materials: use analytical reagents to prepare basic mineral wool raw materials, in which the content of CaO in the basic mineral wool raw materials is 30.50%, SiO 2 The content is 49.51%, Al 2 o 3 The content is 12.03%, the MgO content is 7.96%, and the acidity coefficient is 1.60;

[0037] Blowing to form fibers: Use the control computer to control the lifting device to descend, so that the stopper rod and the bottom outlet of the crucible are tightly closed; the prepared mineral wool raw materials are put into the crucible, and the high temperature resistance furnace is heated at 15°C / min. Turn on the air compressor immediately after the heating rate reaches 1500°C. When the outlet pressure of the high-pressure nozzle reaches 0.4Mpa and the temperature in the high-temperature resistance furnace is kept at 1500°C for 30 minutes, control the lifting device to rise, and the stopper rod and the crucible of the material are released. The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com