Method for pretreating phosphogypsum by using steel slag

A phosphogypsum and pretreatment technology, which is applied in the field of industrial waste resource treatment, can solve the problems of incomplete industrial production, environmental pollution, and increased costs, and achieves good impurity removal and whitening effects, less environmental and human damage, and easy operation. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

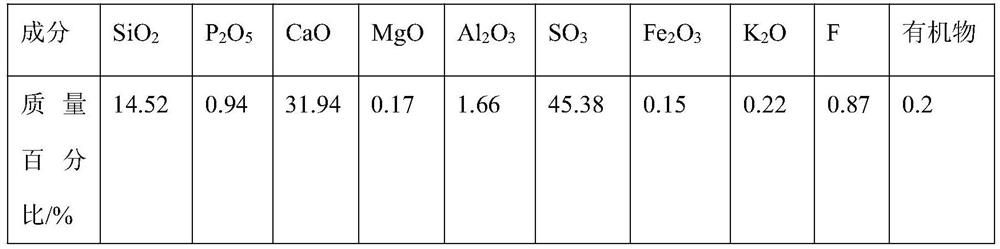

[0020] Embodiment 1: a kind of method utilizing steel slag pretreatment phosphogypsum, comprises the following steps:

[0021] Step 1: Mix steel slag and water, stir evenly, collect steel slag leaching solution after filtration for use; wherein water and steel slag are mixed in a mass ratio of 1:2.2;

[0022] Step 2: Take the phosphogypsum raw material, sieve it with a sieve with a filter hole of 0.20 mm, collect the sieved phosphogypsum, and age it for 24 hours for use;

[0023] Step 3: washing the phosphogypsum obtained in step 2 with a sulfuric acid solution with a mass fraction of 30%, and collecting the phosphogypsum filter residue after filtering;

[0024] Step 4: Fully mix the phosphogypsum filter residue obtained in Step 3 and the steel slag filtrate collected in Step 1 at a mass ratio of 1:0.429;

[0025] Step 5: fully stir the mixed material obtained in step 4, and measure the pH until the pH value of the material is in the range of 7-9;

[0026] Step 6: wash the m...

Embodiment 2

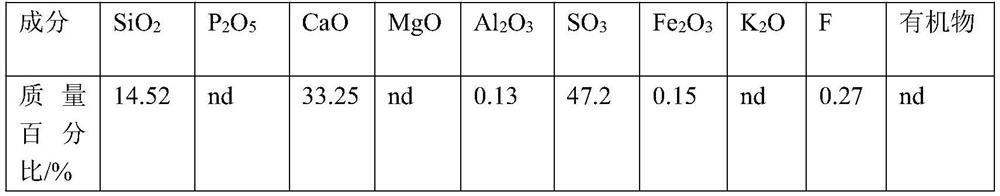

[0032] Embodiment 2: a kind of method utilizing steel slag pretreatment phosphogypsum, comprises the following steps:

[0033] Step 1: Mix steel slag and water, stir evenly, collect steel slag leaching solution after filtration for use; wherein water and steel slag are mixed in a mass ratio of 1:2.2;

[0034] Step 2: Take the phosphogypsum raw material, sieve it with a sieve with a filter hole of 0.20 mm, collect the sieved phosphogypsum, and age it for 24 hours for use;

[0035] Step 3: washing the phosphogypsum obtained in step 2 with a sulfuric acid solution with a mass fraction of 28%, and collecting the phosphogypsum filter residue after filtering;

[0036] Step 4: Fully mix the phosphogypsum filter residue obtained in Step 3 and the steel slag filtrate collected in Step 1 at a mass ratio of 1:0.429;

[0037] Step 5: fully stir the mixed material obtained in step 4, and measure the pH until the pH value of the material is in the range of 7-9;

[0038] Step 6: Wash the m...

Embodiment 3

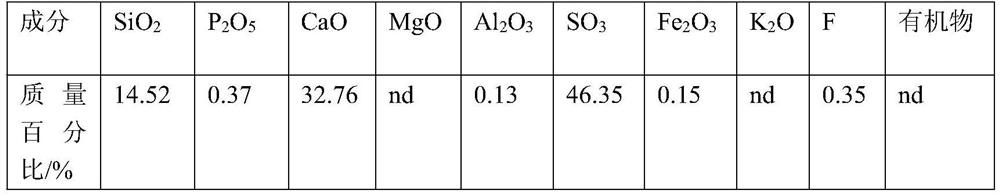

[0044] Embodiment 3: a kind of method utilizing steel slag pretreatment phosphogypsum, comprises the following steps:

[0045] Step 1: Mix the steel slag and water, stir evenly, collect the steel slag leach solution after filtration for use; wherein water and steel slag are mixed in a mass ratio of 1:2;

[0046] Step 2: Take the phosphogypsum raw material, sieve it through a sieve with a filter hole of 0.20 mm, collect the sieved phosphogypsum, and age it for 30 hours for use;

[0047] Step 3: washing the phosphogypsum obtained in step 2 with a sulfuric acid solution with a mass fraction of 28%, and collecting the phosphogypsum filter residue after filtering;

[0048] Step 4: Fully mix the phosphogypsum filter residue obtained in Step 3 and the steel slag filtrate collected in Step 1 according to the mass ratio of 1:0.428;

[0049] Step 5: fully stir the mixed material obtained in step 4, and measure the pH until the pH value of the material is in the range of 7-9;

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com