A high-proportion pellet blast furnace ironmaking method

A blast furnace ironmaking and pelletizing technology, applied in the blast furnace, blast furnace details, blast furnace parts, etc., can solve the problems of poor thermal stability of blast furnace, high metallurgical comprehensive performance, wind suffocation, etc., to accelerate the process of reduction and softening of molten droplets , Improve economic benefits, increase the effect of indirect reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

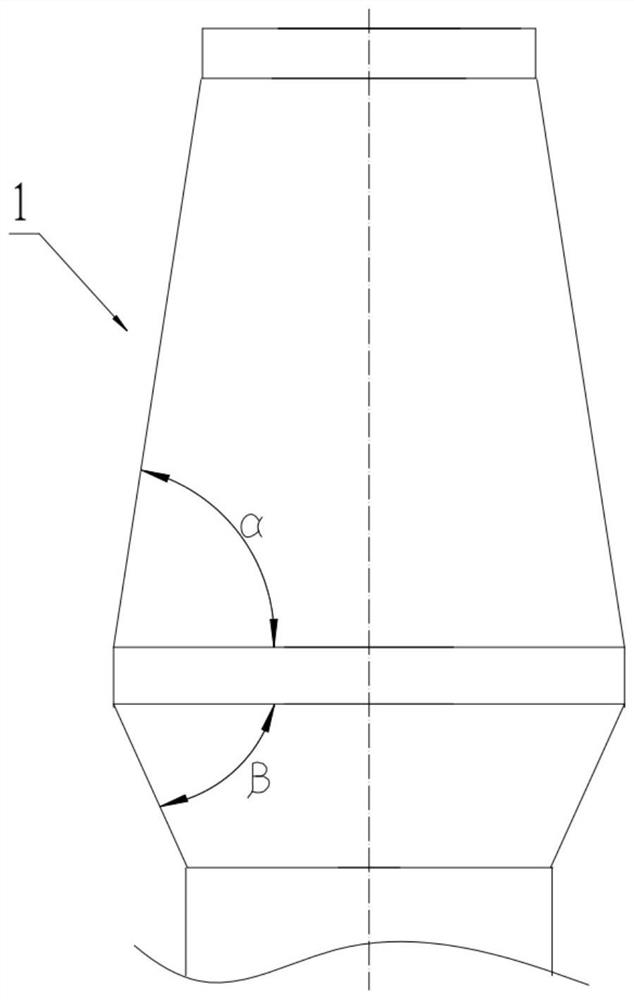

[0025] Embodiment 1: In the blast furnace smelting process, the ore material composed of iron-containing charge, coke and limestone is sent into the blast furnace from the top of the furnace. The iron-containing charge includes pellets and sintered ore, wherein the proportion of pellets is 70%; the ore The mass parts of iron-containing furnace materials in the feed are 75 parts by mass, the parts by mass of coke are 25 parts by mass, and the parts by mass of limestone are 0.5 parts by mass.

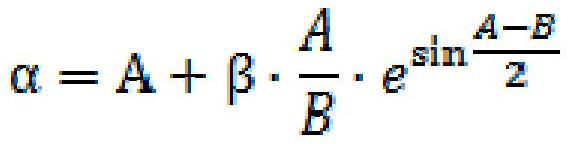

[0026] The bosh angle β of the blast furnace is 75.5°, A is 1.4°, B is 0.9A=1.26°, and α is calculated from formula 1 to be 85.39°.

[0027] The oxygen enrichment rate is 12%, and the amount of coal injection in the blast furnace ironmaking process is 180kg / tHM; mixed pulverized coal is used for injection, and the proportion of bituminous coal in the mixed pulverized coal is 50%; Gas 60m3 / tHM, coke ratio control 300kg / tHM.

Embodiment 2

[0028] Embodiment 2: In the blast furnace smelting process, the ore material composed of iron-containing charge, coke and limestone is sent into the blast furnace from the top of the furnace. The iron-containing charge includes pellets and sintered ore, wherein the proportion of pellets is 78%; the ore The mass fraction of iron-containing charge in the material is 78, and the mass fraction of coke is 22.

[0029] The bosh angle β of the blast furnace is 76°, A is 1.2°, B is 0.92A=1.104°, and α is calculated from formula 1 to be 83.88°.

[0030]The oxygen enrichment rate is 13%, and the amount of coal injection in the blast furnace ironmaking process is 190kg / tHM; mixed pulverized coal is used for injection, and the proportion of bituminous coal in the mixed pulverized coal is 70%; Gas 60m3 / tHM, coke ratio control 315kg / tHM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com