Silicon-Silicon Nitride Integrated Polarizing Beam Splitter Based on Vertical Coupling Structure

A polarization beam splitter and vertical coupling technology, applied in the direction of instruments, light guides, optics, etc., can solve the problems of small manufacturing capacity of directional couplers, unfavorable large-scale photon integration, large horizontal size of devices, etc., to reduce the coupling length, Effect of compact structure and short longitudinal length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

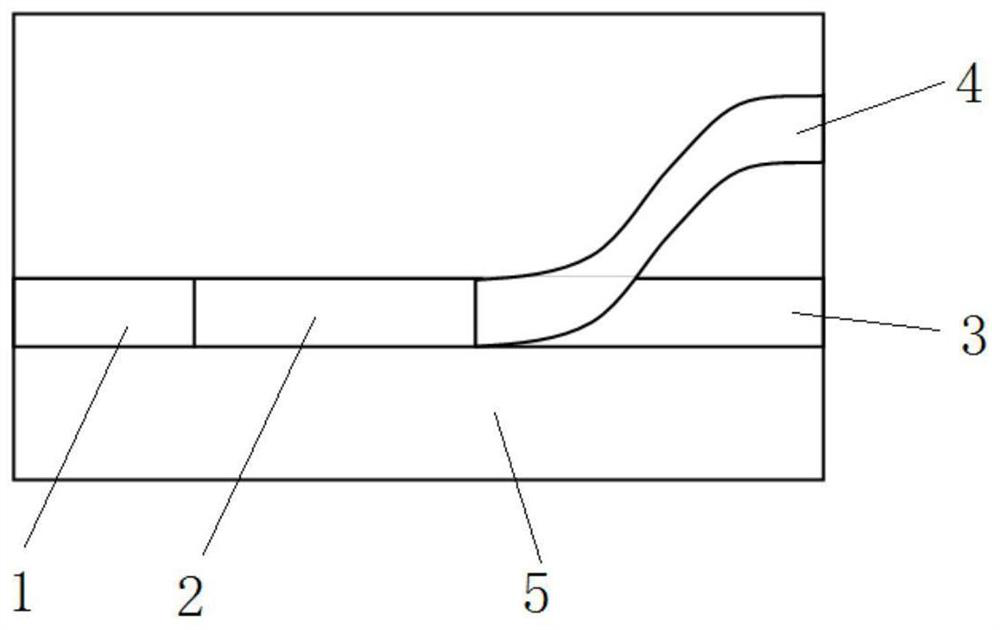

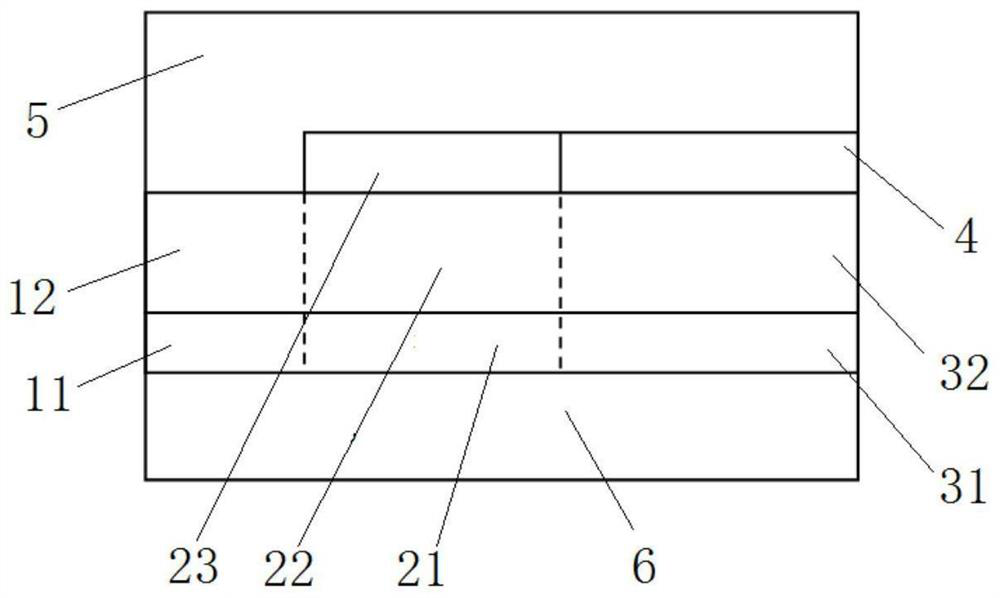

[0022] Such as figure 1 , the silicon-silicon nitride integrated polarization beam splitter based on the vertical coupling structure described in this embodiment includes an input waveguide 1, a polarization beam splitting waveguide 2, a first output waveguide 3 and a second output waveguide 4, and is coated on In the outermost cladding layer 5 of the polarization beam splitter, the input waveguide 1 is connected to one end of the polarization beam splitting waveguide 2, and the other end of the polarization beam splitting waveguide 2 is respectively connected to the first output waveguide 3 and the second output waveguide 4, and the polarization beam splitting waveguide 2 It is a three-layer structure composed of silicon-silicon nitride-silicon distributed sequentially from bottom to top. The polarizing beam splitter in this embodiment is fabricated on a silicon dioxide substrate 6 .

[0023] The input waveguide 1 and the first output waveguide 3 are two-layer structures com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com