Double-sided heat dissipation power semiconductor module and manufacturing method thereof

A power semiconductor, double-sided heat dissipation technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of low production yield and inconsistent chip height, and reduce life and reliability. , uniform distribution, the effect of reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

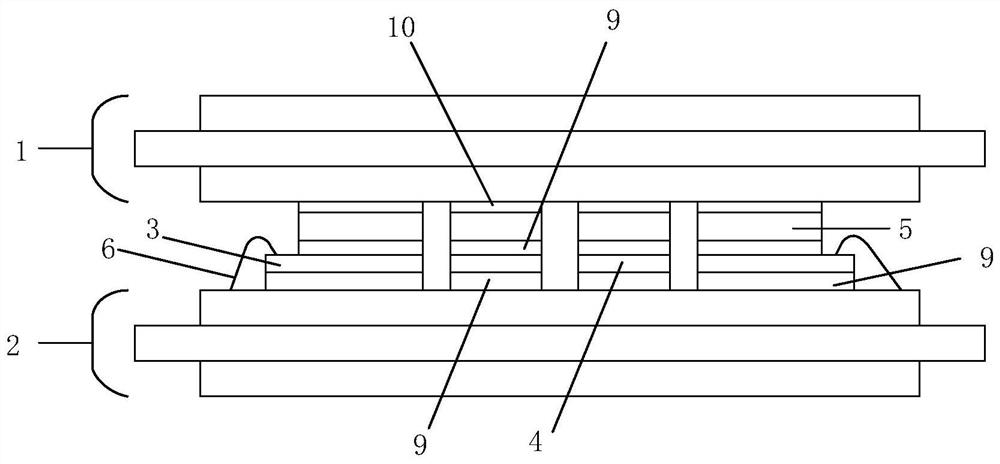

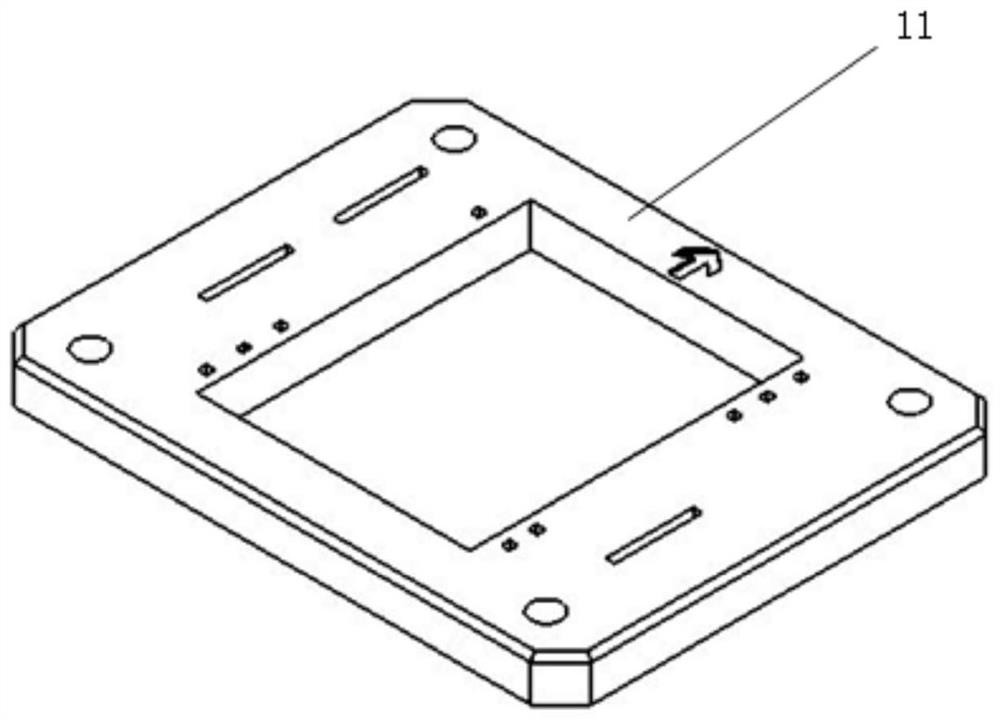

[0032] Embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings.

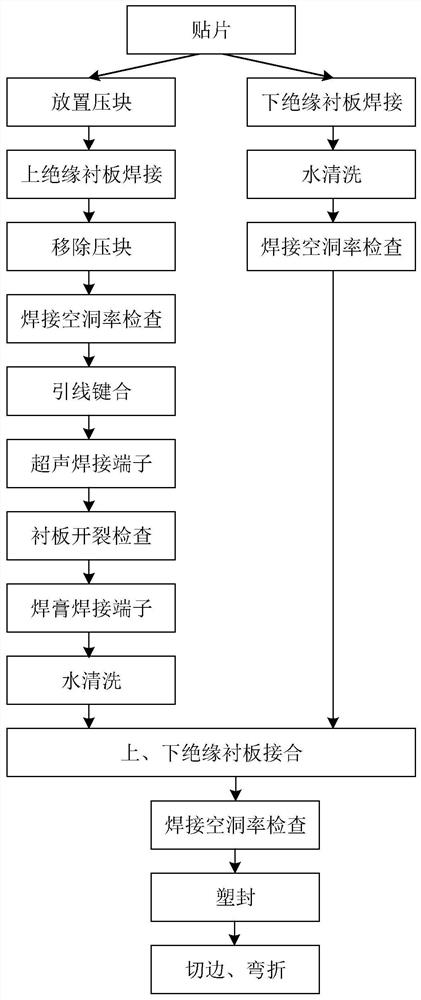

[0033] A double-sided heat dissipation power semiconductor module manufacturing method proposed by the present invention adopts the process of "bonding + secondary welding" for welding the power / signal terminals, which limits the bonding parameters selected by the power / signal terminals, and the selection is omitted. Small bonding parameters ensure that the insulating liner will not crack due to excessive bonding parameters, and the subsequent secondary welding process steps further strengthen the welding strength, avoiding the traditional welding process using high-energy bonding parameters to cause cracking of the insulating liner , and it is necessary to adjust the process parameters by trial and error before producing a certain module, which takes a lot of time and cost, and there will be defects of low production yield.

[0034] The structure of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com