Production method of tilapia fillets

A production method, technology of tilapia fillets, applied in freezing/cooling preservation of meat/fish, food science, etc., can solve problems such as hardening of fish meat, decline in quality of fish fillets, and large fishy smell of tilapia fillets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

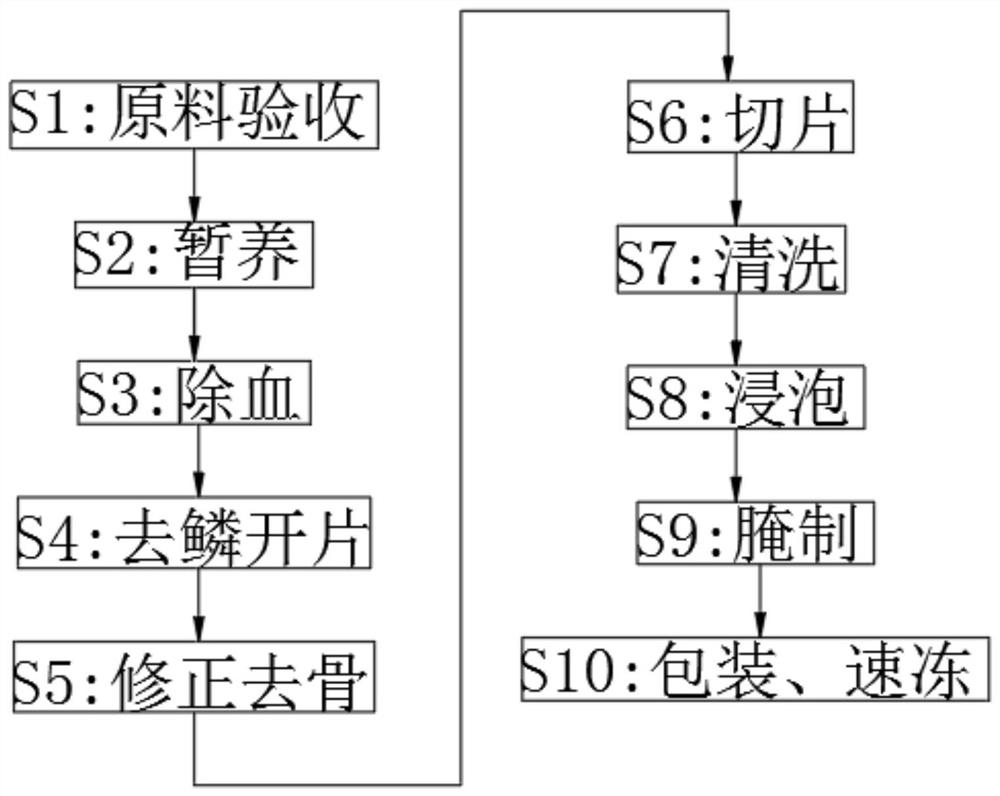

[0049] Such as Figure 1-3 Shown, present embodiment discloses a kind of production method of tilapia fillet, comprises the steps:

[0050] S1: Acceptance of raw materials, sampling and testing the appearance of tilapia to ensure the health of this batch of tilapia and ensure that there are no diseased or infected fish;

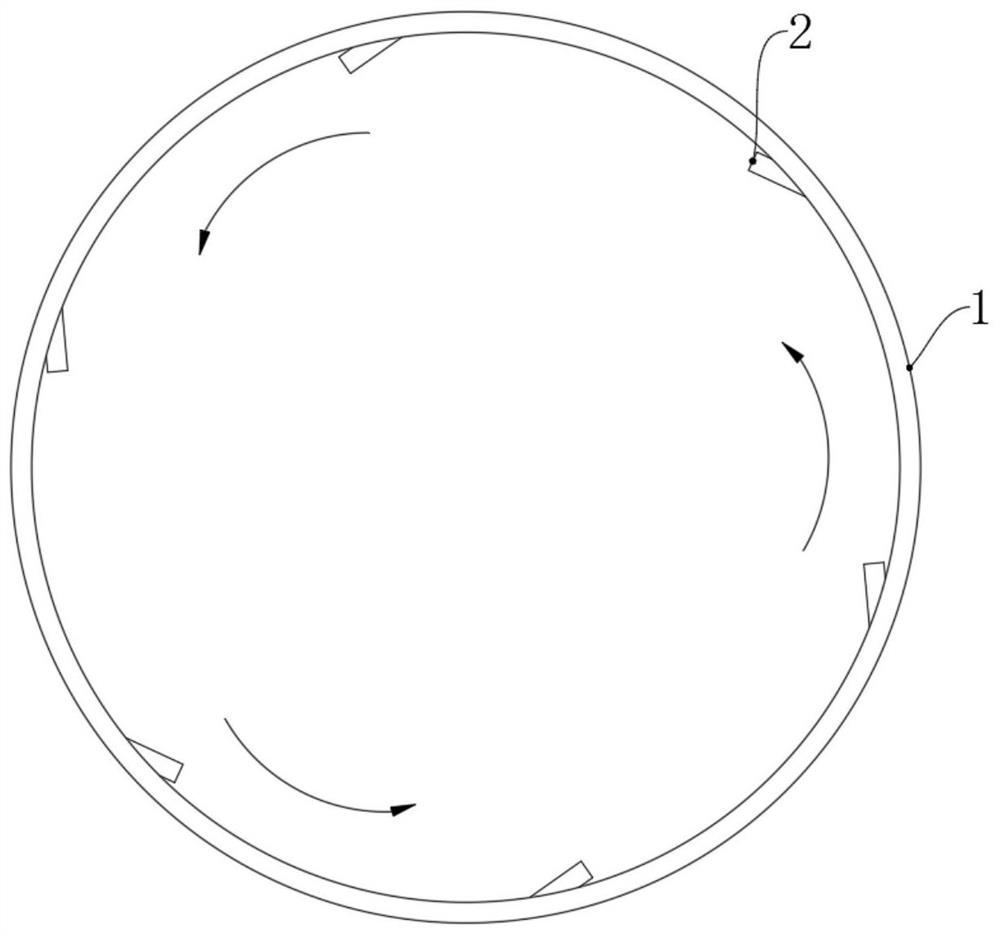

[0051] S2: The tilapia after the acceptance is sent to the holding pond 1 for temporary raising, and a sufficient amount of oxygen is introduced into the holding pond 1, and sodium chloride is added in the holding pond 1, and the concentration of sodium chloride is 0.1-0.3%. A water circulation device is provided in the temporary storage pool 1, and the water circulation device includes an outlet pipe 2 that is inclined to be arranged on the side of the temporary storage pool 1. The outlet pipe 2 is connected with a water pump, and the water pump is located in the temporary storage pool 1. After the water in the raising pond 1 is ejected from the outlet pipe...

Embodiment 2

[0072] The present embodiment is basically similar to Embodiment 1, the difference is that in the present embodiment, the holding pond 1 is a square holding pond, and a water circulation device is arranged on the holding pond in the square, so that in the holding pond of the square temporarily The liquid flows, wherein, there is electrochemical water for fishing in the square holding pond. The use of flowing electrolytic water for fish can disinfect and sterilize the surface of the fish body, and at the same time, make the fish body more active.

[0073] Wherein, the water circulation device includes a water pump and some outlet pipes 2, the water pump is located in the holding pond, the outlet pipe is arranged on the side of the holding pond, the outlet pipe 2 is connected with the water pump, and under the action of the water pump, the water in the holding pond flows from the outlet After spraying out from the water pipe, the water in the holding pond is in a flowing state; ...

Embodiment 3

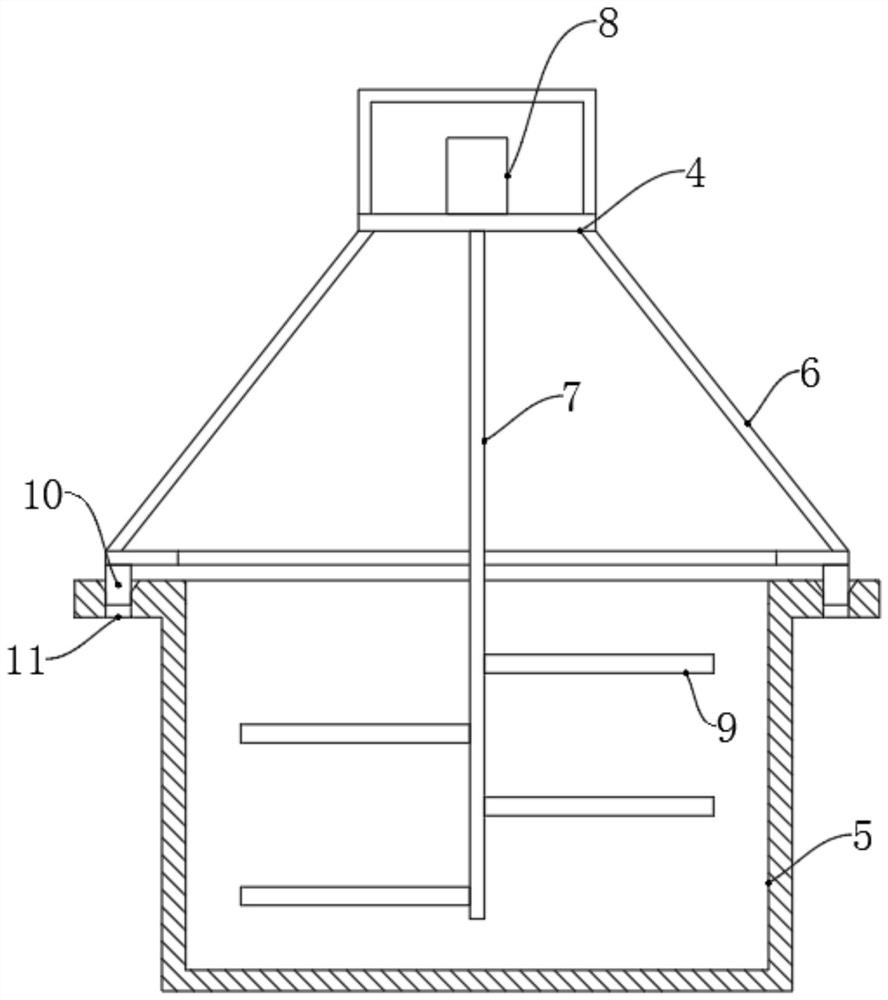

[0078] Such as Figure 4 and Figure 5 As shown, the present embodiment is further optimized on the basis of Embodiment 1. In the present embodiment, the tumbler 3 of the following structure is adopted in S9 to pickle; the tumbler 3 includes a base 12, a tumbler 13 and the driving device 14, the tumbler 13 is provided with a feed port 15, the feed port 15 is provided with a material gate 16 that can be opened and closed, the feed port 15 is used for feeding and discharging, and the left and right ends of the tumbler 13 are provided with Rotating shaft 17, the tumbler 13 is installed on the base 12 through the rotation of the rotating shaft 17, the drive device 14 is installed on the base 12 and connected with the rotating shaft 17 at one end of the tumbler 13, the drive unit 14 can drive the tumbler 13 Rotation; in the tumble drum 13 near the two ends, there are respectively provided a first stopper assembly 18 and a second stopper assembly 19, the first stopper assembly 18 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com