Preparation method of shell-core structure molecular sieve catalyst for biomass pyrolysis reforming upgrading

A biomass pyrolysis and molecular sieve technology, which is applied in molecular sieve catalysts, catalyst activation/preparation, preparation of liquid hydrocarbon mixtures, etc., can solve problems such as product escape, insufficient surface acidity, poor catalytic effect, etc., and prolong service life , High skeleton stability, good for adsorption and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

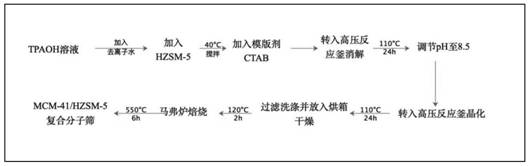

[0028] The preparation method of the shell-core structure molecular sieve catalyst of the present invention comprises the following steps:

[0029] Step 1. Add a certain amount of deionized water into the beaker, measure 40% TPAOH solution and add it to the deionized water, then weigh HZSM-5 molecular sieve powder and add it to the solution for rapid stirring. Place it on a magnetic stirrer at 35-60 Stir well at °C. After 1 hour, weigh and dissolve the template agent CTAB into a 10% concentration solution, add it to the suspension, and stir thoroughly at 15-30°C for 1 hour.

[0030] Step 2. After fully stirring the suspension in step 1, move it to a tetrafluoroethylene-lined autoclave, place the autoclave in an oven, and digest it for 12 to 36 hours at 90 to 120°C.

[0031] Step 3: Take out the reaction kettle, open it after cooling to normal temperature, adjust its pH value to 8-9 with 5% dilute sulfuric acid, then move it back to the high-pressure reaction kettle, and heat ...

Embodiment 1

[0034] Example 1 A method for preparing a shell-core structured molecular sieve catalyst for biomass pyrolysis reforming and upgrading

[0035] The preparation method of mesoporous composite molecular sieve among the present invention is as figure 1 shown, including the following steps:

[0036] Step 1. Add a certain amount of deionized water into the beaker, measure 40% TPAOH solution (mass ratio to water: 2.6:1) into deionized water, and then weigh HZSM-5 molecular sieve powder (mass ratio to TPAOH solution: 1 :5) Add it into the solution and stir quickly, place it on a magnetic stirrer and stir fully at 40°C. After 1 h, weigh the template agent CTAB (mass ratio to TPAOH solution: 1.6:1) and dissolve it to a 10% concentration solution, add it to the suspension, and stir thoroughly at 20°C for 1 h.

[0037]Step 2. After fully stirring the suspension in step 1, move it to a tetrafluoroethylene-lined autoclave, place the autoclave in an oven, and digest it for 24h at 110°C. ...

Embodiment 2

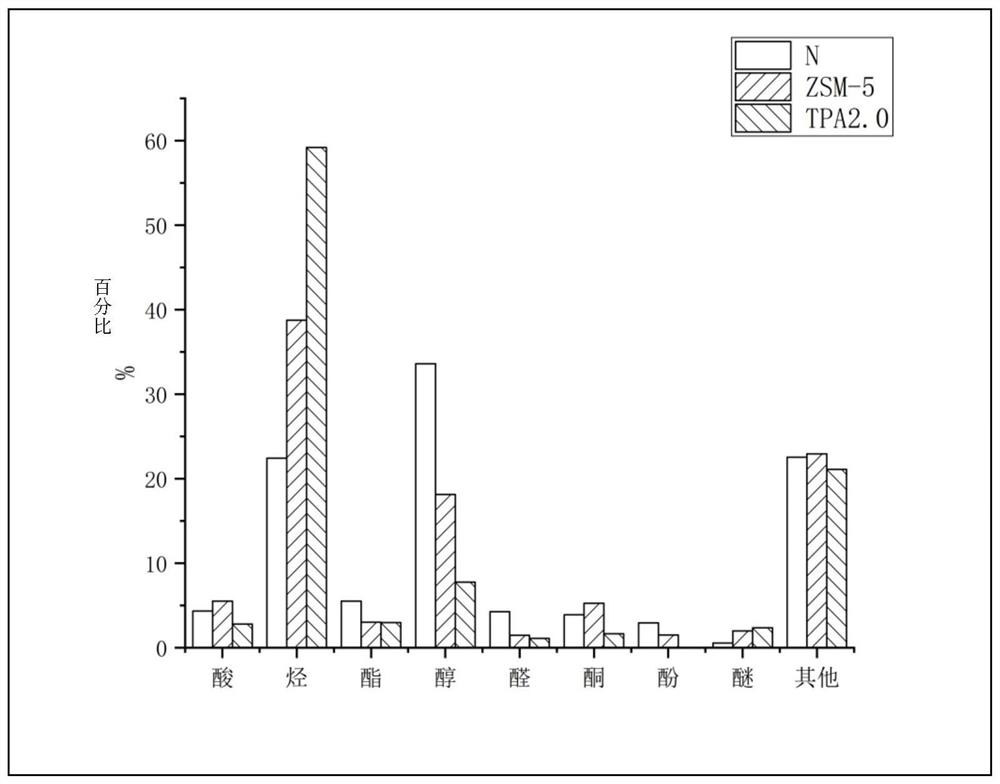

[0041] The composite molecular sieve prepared in Example 1 was used to carry out the catalytic pyrolysis test on algae, and the pyrolysis-gas chromatography / mass spectrometry (Py / GC-MS) reaction device was used to compare non-catalytic pyrolysis and HZSM-5 catalytic Product distribution of pyrolysis and MCM-41 / HZSM-5 composite molecular sieve catalyzed pyrolysis.

[0042] Spirulina was selected as biomass, passed through a 10-mesh sieve and dried for storage before the experiment. The inner diameter of the quartz tube used for the non-catalytic pyrolysis of spirulina is 1.9 mm, and the length is 25 mm. Use a balance to weigh 0.5 mg of spirulina with weighing paper and add it to the tube. Quartz wool is used on both sides to fix the spirulina, from left to right Followed by quartz wool, spirulina, quartz wool. When adding the catalyst, from left to right are quartz wool, catalyst, quartz wool, spirulina, quartz wool, catalyst, quartz wool. The catalytic pyrolysis temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com