Novel environment-friendly high-corrosion-resistance zinc-aluminum coating

A green environmental protection, zinc-aluminum technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of high solvent volatilization, low hardness, high price, etc., and achieve the effect of excellent salt spray resistance, excellent performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

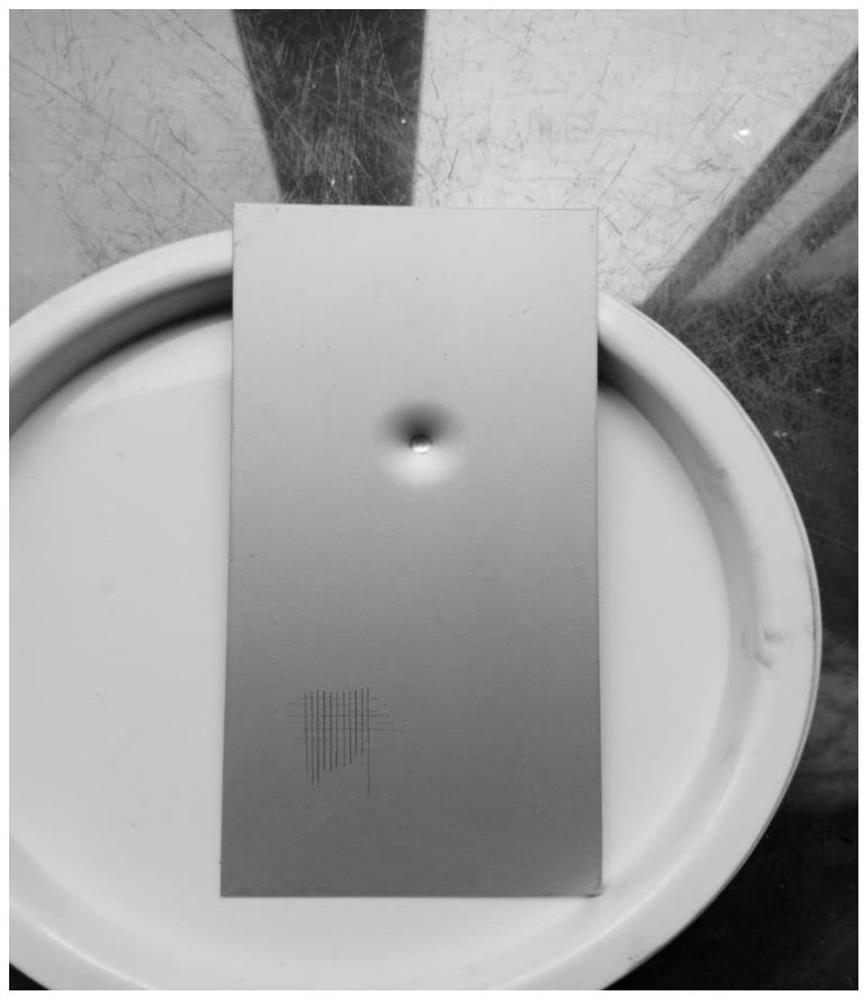

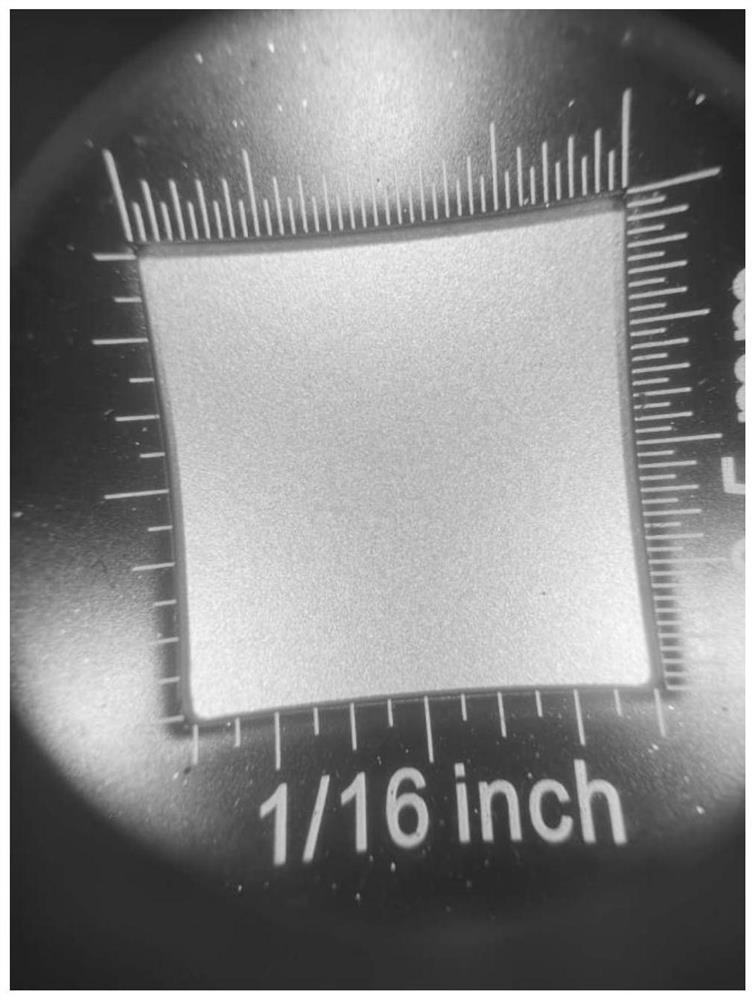

Image

Examples

preparation example Construction

[0036] A method for preparing a green, environment-friendly, high-corrosion zinc-aluminum coating, comprising the following steps:

[0037] 1) Add zinc-aluminum powder to high-boiling-point alcohols, stir, wet and soak for 12 hours to obtain zinc-aluminum paste;

[0038] 2) Measure the zinc-aluminum slurry obtained in step 1) under stirring and slowly pour it into the green environmental protection resin until it is evenly dispersed, then filter to obtain the zinc-aluminum coating.

Embodiment 1

[0039] Embodiment 1: the preparation method of green environmental protection resin

[0040] A kind of green environment-friendly resin, its preparation method is: after taking 1 weight part of KH550, 4 weight parts of methyltrimethoxysilane and 5 weight parts of nano-titanium dioxide sol, after mixing and stirring, it is hydrolyzed with an acid solution of 0.9 times the mass of the solution, and then heated up to distill out The generated methanol / ethanol, after the distillation is completed, is added with lye to adjust the pH value of the solution to neutral to obtain a green resin.

Embodiment 2

[0041] Embodiment 2: the preparation method of green environmental protection resin

[0042] A kind of green environment-friendly resin, its preparation method is: after getting 2 weight parts of KH550, 3 weight parts of KH560, 4 weight parts of ethyl orthosilicate and 5 weight parts of nano-silica sols and mix and stir, use the acid of 0.8 times of solution quality After the solution is hydrolyzed, the temperature is raised to distill the generated methanol / ethanol. After the distillation is completed, lye is added to adjust the pH value of the solution to neutral to obtain a green resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com