A kind of low-viscosity high-strength toughened silicone resin composition and preparation method thereof

A silicone resin composition and high-strength technology, which is applied in the field of silicone polymers, can solve the problems of difficult toughening effects due to co-hydrolysis of functional monomers, and achieve the goals of improving resin strength, excellent comprehensive performance, and improving reinforcement effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

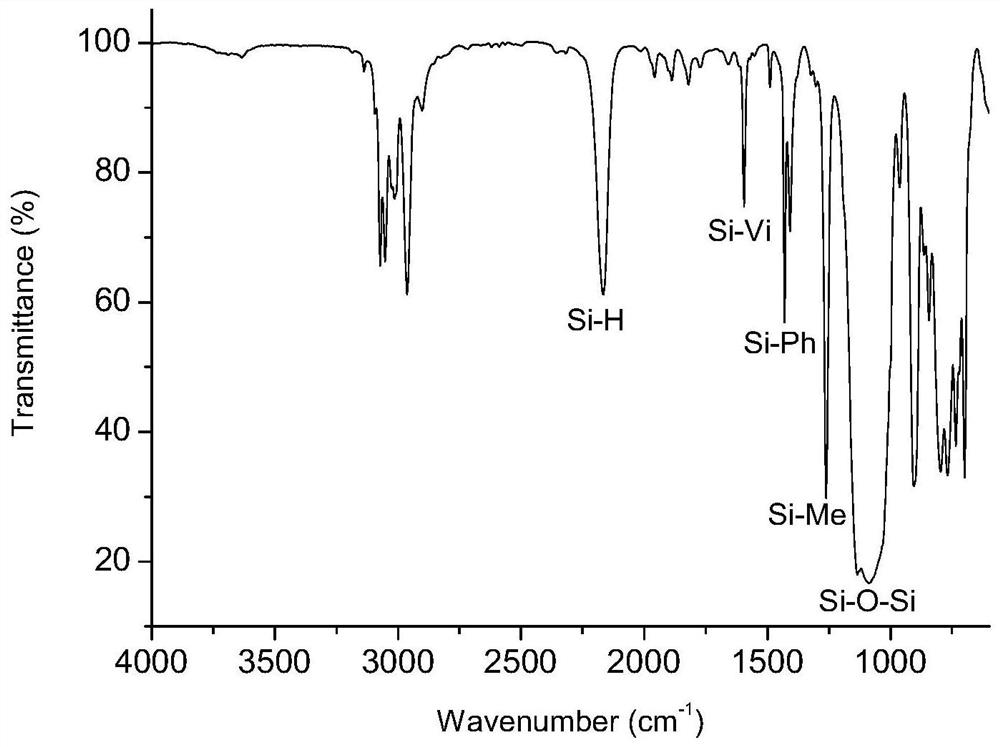

Image

Examples

Embodiment 1

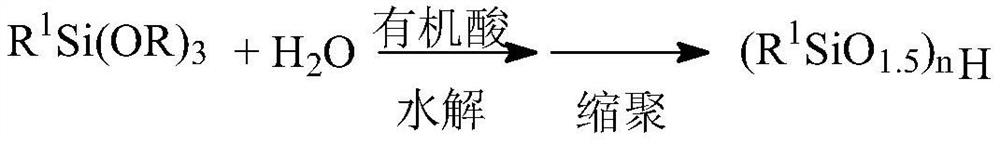

[0033] Add 172.8 g of deionized water, 400 g of toluene, and 10 g of acetic acid into a four-necked flask equipped with a thermometer, a stirring paddle, and a reflux condenser, stir evenly, and add 1,057 g of phenyltrimethoxysilane dropwise. After the addition, the temperature was raised to reflux, reacted for 2h, and then cooled to room temperature. The low boilers were distilled off at a pressure of less than 10KPa at 80°C to obtain 680g of a liquid trifunctional silicone resin prepolymer.

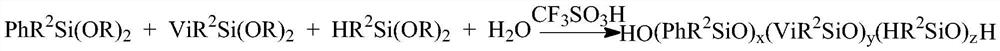

[0034] Add 270 g of deionized water, 0.38 g of trifluoromethanesulfonic acid, and 500 g of toluene into a four-necked flask equipped with a thermometer, a stirring paddle, and a reflux condenser, stir evenly, and dropwise add 900 g of methylphenyldimethoxysilane, A mixed solution consisting of 261 g of methylvinyldimethoxysilane and 262 g of methylvinyldimethoxysilane. After the addition, the reaction was refluxed for 2 hours, cooled to room temperature, and the layers were separated, ...

Embodiment 2

[0037] Add 172.8 g of deionized water, 400 g of toluene, and 10 g of acetic acid into a four-neck flask equipped with a thermometer, a stirring paddle, and a reflux condenser, stir evenly, and add 952 g of phenyltrimethoxysilane dropwise. After the addition, the temperature was raised to reflux, reacted for 2h, and then cooled to room temperature. The low boilers were distilled off at a pressure of less than 10 KPa at 80° C. to obtain 610 g of a liquid trifunctional silicone resin prepolymer.

[0038] Add 402 g of deionized water, 0.5 g of trifluoromethanesulfonic acid, and 600 g of toluene into a four-necked flask equipped with a thermometer, a stirring paddle, and a reflux condenser, stir evenly, and dropwise add 900 g of methylphenyldimethoxysilane, A mixed solution consisting of 371 g of methylvinyldimethoxysilane and 366 g of methylvinyldimethoxysilane. After the addition, the reaction was refluxed for 2 hours, cooled to room temperature, and the layers were separated, a...

Embodiment 3

[0041] Add 144 g of deionized water, 300 g of toluene, and 8 g of acetic acid into a four-necked flask equipped with a thermometer, a stirring paddle, and a reflux condenser, stir evenly, and add 793 g of phenyltrimethoxysilane dropwise. After the addition, the temperature was raised to reflux, reacted for 2h, and then cooled to room temperature. The low boilers were distilled off at a pressure of less than 10KPa at 80°C to obtain 510g of a liquid trifunctional silicone resin prepolymer.

[0042] Add 355 g of deionized water, 0.4 g of trifluoromethanesulfonic acid, and 500 g of toluene into a four-necked flask equipped with a thermometer, a stirring paddle, and a reflux condenser, stir evenly, and dropwise add 900 g of methylphenyldimethoxysilane, A mixed solution consisting of 293 g of methylvinyldimethoxysilane and 288 g of methylvinyldimethoxysilane. After the addition, the reaction was refluxed for 2 hours, cooled to room temperature, and the layers were separated, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com