Preparation method of alkynyl bond-containing polyether modified organic silicon

An acetylenic bond polyether and organosilicon technology is applied in the field of preparation of acetylene bond-containing polyether modified organosilicon, which can solve the problems of many reaction by-products, low conversion rate, long reaction time, etc. The effect of shortening the reaction rate and reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

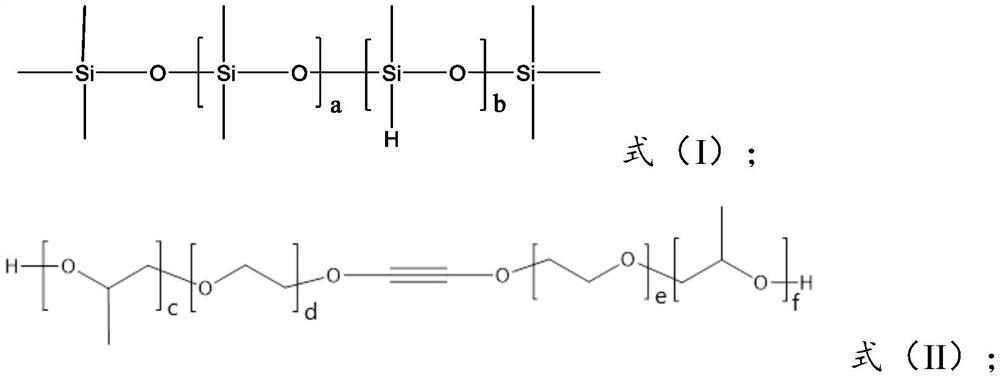

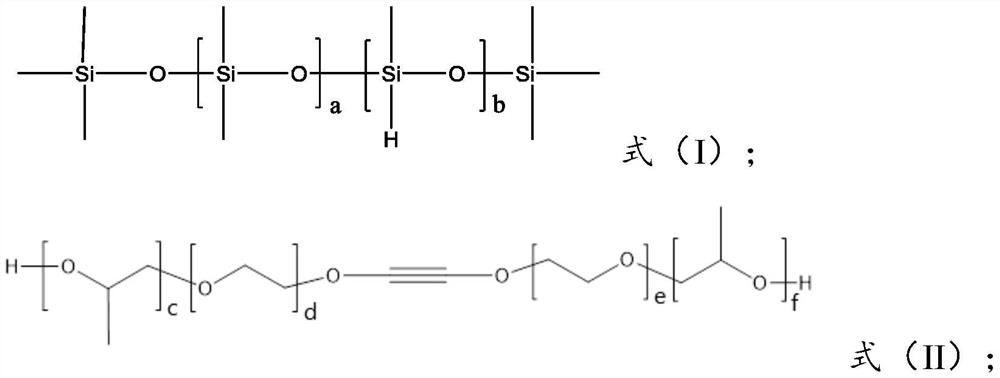

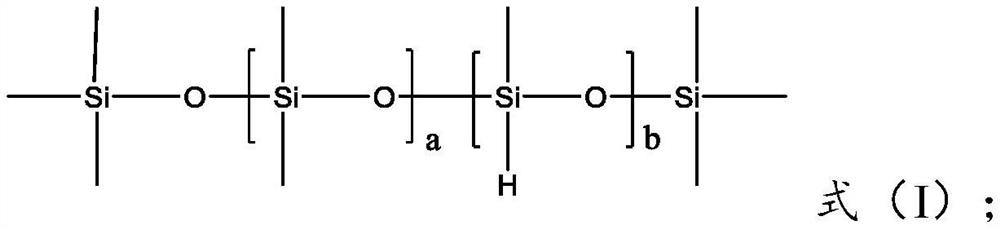

[0022] The invention provides a method for preparing polyether-modified organosilicon containing acetylenic bonds, comprising: S) carrying out pressurized heating reaction of hydrogen-containing polysiloxane, acetylenic polyether and transition metal catalyst in a closed container to obtain Alkyne bond-containing polyether modified silicone.

[0023] The invention improves the reaction rate through the pressurized reaction, thereby shortening the reaction time, and can effectively suppress the occurrence of side reactions and improve the conversion rate at the same time.

[0024] The present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0025] Wherein, the molecular weight of the hydrogen-containing polysiloxane is preferably 1000-5000, more preferably 1000-4000, more preferably 1000-3000, most preferably 2000; the hydrogen content in the hydrogen-containing polysiloxane is preferably 0.1%~0.5%; the hydrogen-co...

Embodiment 1

[0042] Add 100 parts of low hydrogen-containing polysiloxane A, 60 parts of acetylenic polyether B, and 20PPM chloroplatinic acid catalyst into the autoclave, and seal the autoclave.

[0043] Slowly fill high-purity nitrogen into the autoclave to pressurize to 0.3 MPa in the autoclave; slowly heat up to 140 °C at a heating rate of 4 °C / min, react for 2 hours, observe and record the temperature change; after the reaction, measure Hydrogen content, viscosity, etc., and the surface tension of its 0.1% aqueous solution was measured with a surface tensiometer, and the results are shown in Table 1.

Embodiment 2

[0045] Add 100 parts of low hydrogen-containing siloxane A, 32 parts of alkyne polyether B, and 20PPM chloroplatinic acid catalyst into the autoclave, and seal the autoclave.

[0046] Slowly fill high-purity nitrogen into the autoclave to pressurize to 0.3 MPa in the autoclave; then slowly heat up to 140 °C at a heating rate of 4 °C / min, react for 2 hours, observe and record the temperature change; after the reaction, Measure the hydrogen content, viscosity, etc., and measure the surface tension of its 0.1% aqueous solution with a surface tensiometer, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com