Benzene-free mildew-proof putty for interior wall

A putty and interior wall technology, applied in the direction of filling slurry, etc., can solve problems such as limited use range, spots, and mildew on the wall, and achieve the effects of improving interface compatibility, stability, and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

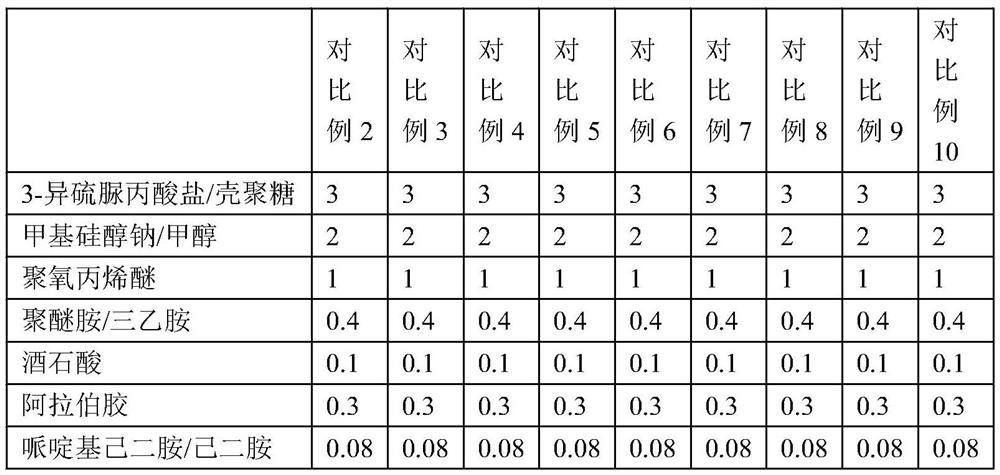

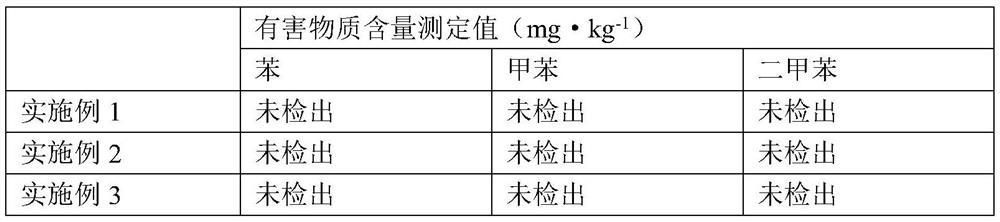

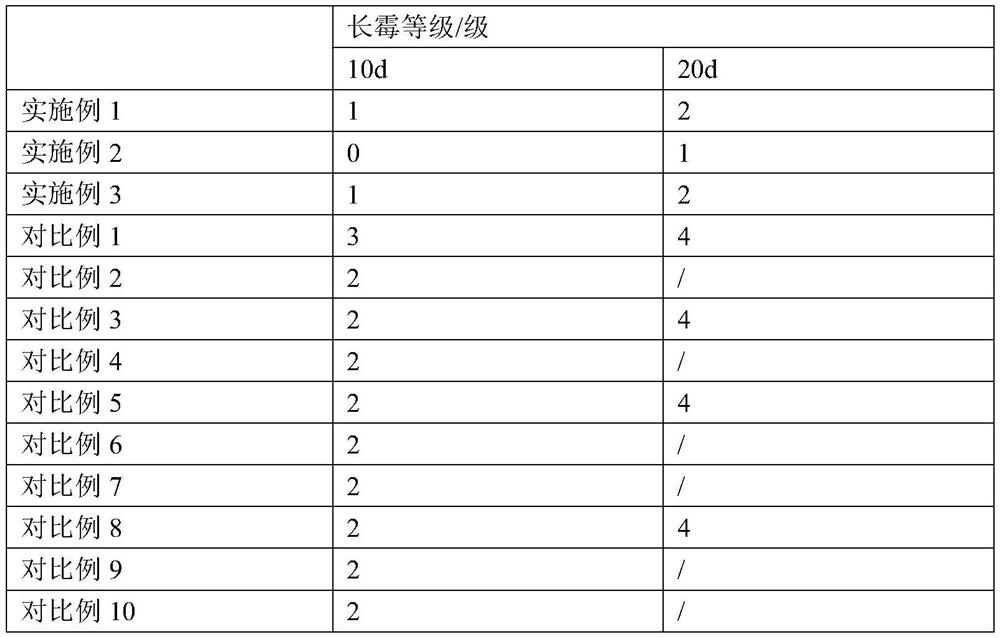

Examples

Embodiment 1

[0041] This application discloses a benzene-free anti-mildew putty for interior walls. The putty includes the following raw materials: 60 parts of heavy calcium carbonate, 8 parts of ash calcium, 20 parts of light calcium carbonate, 0.3 parts of hydroxypropyl methylcellulose, 0.3 parts of Starch ether, 0.1 part of latex powder, 0.3 part of antialkali agent and 2 parts of antifungal agent; antifungal agent includes the following components: 3-isothiourea propionate, sodium methyl siliconate, polyoxypropylene ether, polyether Amine, tartaric acid, gum arabic and piperidinyl hexamethylene diamine; antifungal agent prepared by:

[0042] First mix sodium methyl siliconate and polyoxypropylene ether, stir and mix with ultrasonic power 300W for 25 minutes, then stir and mix with 3-isothiourea propionate for 40 minutes; then add polyetheramine and stir evenly, heat up to 90°C, Add tartaric acid dropwise at a rate of 1 drop / s. After the dropwise addition, continue to stir for 1 hour, t...

Embodiment 2

[0045] This application discloses a benzene-free anti-mildew putty for interior walls. The putty includes the following raw materials: 90 parts of heavy calcium carbonate, 15 parts of gray calcium carbonate, 40 parts of light calcium carbonate, 0.6 parts of hydroxypropyl methylcellulose, 0.6 parts of Starch ether, 0.3 parts of latex powder, 0.8 parts of anti-alkali agent and 3 parts of anti-mold agent; anti-mold agent includes the following components: 3-isothiourea propionate, sodium methyl siliconate, polyoxypropylene ether, polyether Amine, tartaric acid, gum arabic and piperidinyl hexamethylene diamine; antifungal agent prepared by:

[0046] First mix sodium methyl siliconate and polyoxypropylene ether, stir and mix with ultrasonic power 400W for 30 minutes, then stir and mix with 3-isothiourea propionate for 50 minutes; then add polyetheramine and stir evenly, heat up to 100°C, Add tartaric acid dropwise at a rate of 1 drop / s. After the dropwise addition, continue to stir...

Embodiment 3

[0049]This application discloses a benzene-free anti-mildew putty for interior walls. The putty includes the following raw materials: 80 parts of heavy calcium carbonate, 11 parts of gray calcium, 30 parts of light calcium carbonate, 0.5 parts of hydroxypropyl methylcellulose, 0.4 parts of Starch ether, 0.2 parts of latex powder, 0.5 parts of anti-alkali agent and 2.5 parts of anti-mold agent; anti-mold agent includes the following components: 3-isothiourea propionate, sodium methyl siliconate, polyoxypropylene ether, polyether Amine, tartaric acid, gum arabic and piperidinyl hexamethylene diamine; antifungal agent prepared by:

[0050] First mix sodium methyl siliconate and polyoxypropylene ether, stir and mix with ultrasonic power 350W for 28 minutes, then stir and mix with 3-isothiourea propionate for 45 minutes; then add polyetheramine and stir evenly, heat up to 95°C, Add tartaric acid dropwise at a rate of 1 drop / s. After the dropwise addition, continue to stir for 1.5 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com