Plastic part surface antibacterial mildew-proof coating and preparation method thereof

A surface antibacterial, antibacterial and antifungal agent technology, applied in the field of antibacterial plastic parts, can solve the problem of not using antibacterial and antifungal coatings, and achieve good scratch resistance and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

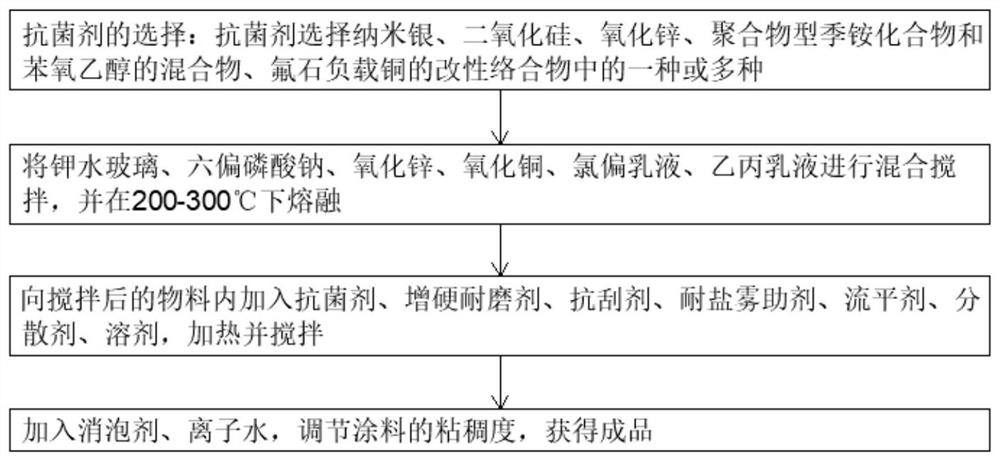

[0020] see figure 1 , in an embodiment of the present invention, an antibacterial and mildew-proof coating on the surface of a plastic part and a preparation method thereof, comprising 30-40 parts of potassium silicate, 0.5-1 part of sodium hexametaphosphate, 2-3 parts of zinc oxide 4-6 parts of copper oxide, 20-30 parts of chlorine partial emulsion, 15-20 parts of ethylene-propylene emulsion, 2-5 parts of antibacterial and antifungal agent, 0.5-2 parts of hardening and wear-resistant agent, 0.5-2 parts of anti-scratch agent 2-5 parts of salt spray resistance additive, 0.1-1 part of leveling agent, 1-3 parts of dispersant, 4-8 parts of solvent.

[0021] Preferably, an antifoaming agent is also included, and the number of parts of the antifoaming agent is 1-3 parts.

[0022] Preferably, the antibacterial and antifungal agent is set to one or more of nano-silver, silicon dioxide, zinc oxide, a mixture of polymeric quaternary ammonium compounds and phenoxyethanol, and a modified...

Embodiment 2

[0033] see figure 1 , in an embodiment of the present invention, an antibacterial and mildew-proof coating on the surface of a plastic part and a preparation method thereof, comprising 30 parts of potassium silicate, 0.5 part of sodium hexametaphosphate, 2 parts of zinc oxide, and 4 parts of copper oxide in parts by mass , 20 parts of chlorine partial emulsion, 15 parts of ethylene-propylene emulsion, 2 parts of antibacterial and antifungal agent, 0.5 part of hardening and wear-resistant agent, 0.5 part of anti-scratch agent, 2 parts of salt spray resistance additive, 0.1 part of leveling agent, dispersant 1 part, 4 parts of solvent.

[0034] Preferably, a defoamer is also included, and the number of parts of the defoamer is 1 part.

[0035] Preferably, the antibacterial and antifungal agent is set to one or more of nano-silver, silicon dioxide, zinc oxide, a mixture of polymeric quaternary ammonium compounds and phenoxyethanol, and a modified complex of fluorspar loaded copp...

Embodiment 3

[0046]see figure 1 , in an embodiment of the present invention, an antibacterial and mildew-proof coating on the surface of a plastic part and a preparation method thereof, comprising 40 parts of potassium silicate, 1 part of sodium hexametaphosphate, 3 parts of zinc oxide, and 6 parts of copper oxide in parts by mass , 30 parts of chlorine partial emulsion, 20 parts of ethylene-propylene emulsion, 5 parts of antibacterial and antifungal agent, 2 parts of hardening and wear-resistant agent, 2 parts of anti-scratch agent, 5 parts of salt spray resistance additive, 1 part of leveling agent, dispersant 3 parts, 8 parts of solvent.

[0047] Preferably, a defoamer is also included, and the number of parts of the defoamer is 3 parts.

[0048] Preferably, the antibacterial and antifungal agent is set to one or more of nano-silver, silicon dioxide, zinc oxide, a mixture of polymeric quaternary ammonium compounds and phenoxyethanol, and a modified complex of fluorspar loaded copper k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com