Method for regulating and controlling number of molybdenum disulfide layers in graphene/molybdenum disulfide heterojunction

A technology of molybdenum disulfide and graphene, which is applied in the direction of coating, gaseous chemical plating, metal material coating process, etc., to achieve high flow rate, convenient operation, excellent uniformity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

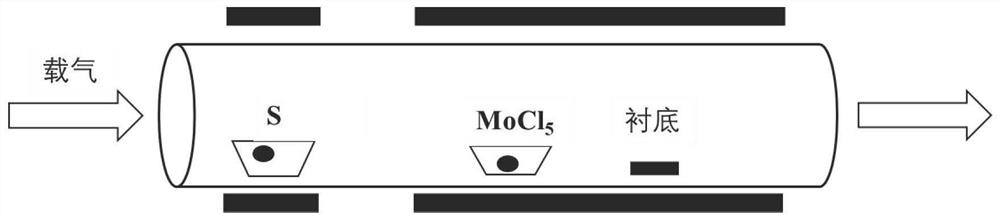

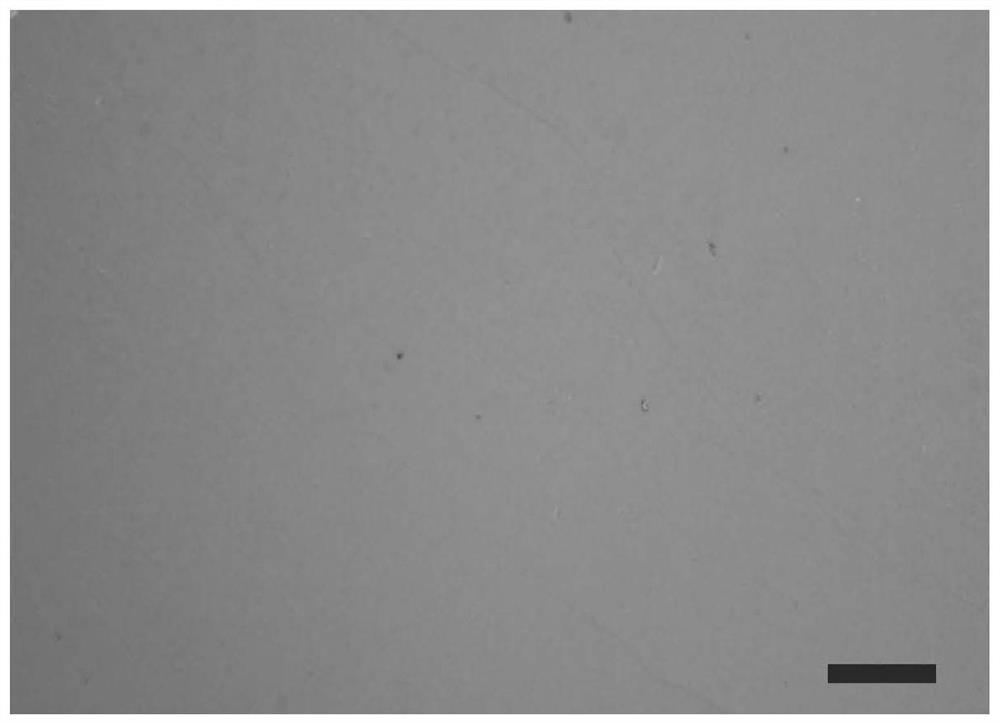

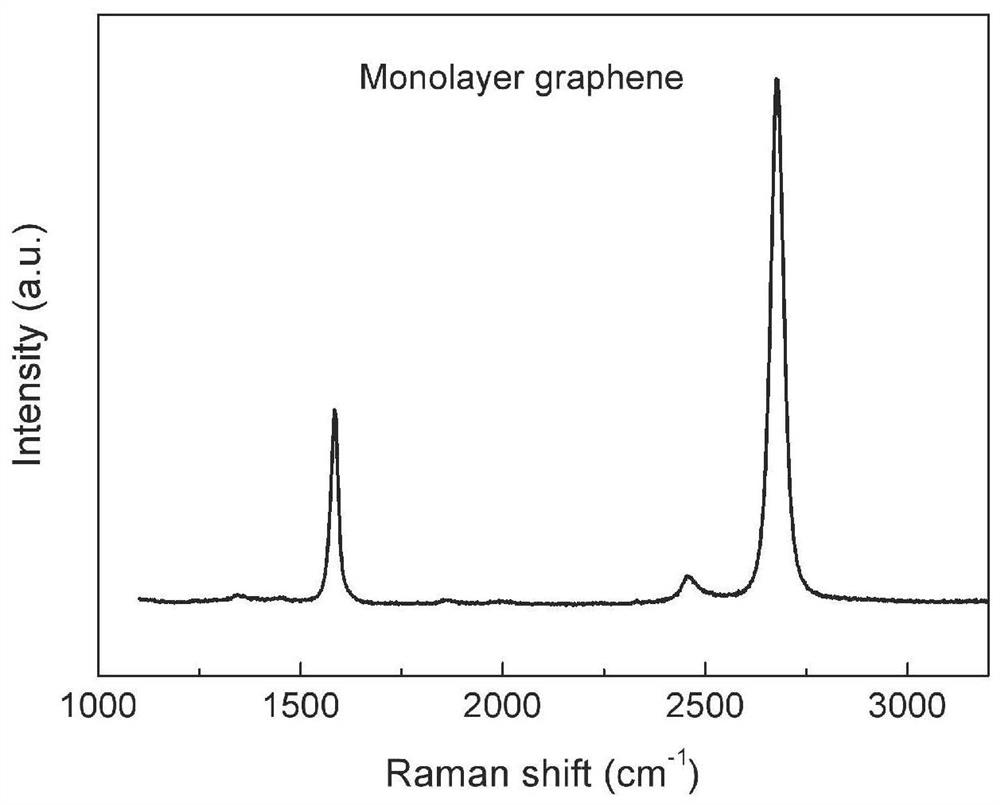

[0056] A method for regulating the number of molybdenum disulfide layers in a graphene / molybdenum disulfide heterojunction provided by a preferred embodiment of the present invention, the specific steps are as follows:

[0057] Pair size 1 x 1cm 2 The silicon dioxide / silicon substrate was ultrasonically treated with acetone, absolute ethanol and deionized water in sequence, and then the surface of the silicon dioxide / silicon substrate was treated hydrophilically with Plasma.

[0058] The copper foil with graphene is cut into required shape, is fixed on PET with adhesive tape edge sealing, then spin-coats on graphene / Front side of copper foil; use 1000rpm to spread the glue for 10s, 3000rpm to shake the glue for 30s, place on a hot plate at 120°C to harden the film for 10min, cut off the tape on the four sides of the copper foil, and remove the PET at the bottom; put 1mol / L ferric chloride aqueous solution on the surface for ~5min , pick up the copper foil with tweezers and t...

Embodiment 2

[0065] A method for regulating the number of molybdenum disulfide layers in a graphene / molybdenum disulfide heterojunction provided by a preferred embodiment of the present invention, the specific steps are as follows:

[0066] Pair size 1 x 1cm 2 The silicon dioxide / silicon substrate was ultrasonically treated with acetone, absolute ethanol and deionized water in sequence, and then the surface of the silicon dioxide / silicon substrate was treated hydrophilically with Plasma.

[0067] The copper foil with graphene is cut into required shape, is fixed on PET with adhesive tape edge sealing, then spin-coats on graphene / Front side of copper foil; use 1000rpm to spread the glue for 10s, 3000rpm to shake the glue for 30s, place on a hot plate at 120°C to harden the film for 10min, cut off the tape on the four sides of the copper foil, and remove the PET at the bottom; put 1mol / L ferric chloride aqueous solution on the surface for ~5min , pick up the copper foil with tweezers and t...

Embodiment 3

[0074] A method for regulating the number of molybdenum disulfide layers in a graphene / molybdenum disulfide heterojunction provided by a preferred embodiment of the present invention, the specific steps are as follows:

[0075] Pair size 1x1 cm 2 The silicon dioxide / silicon substrate was ultrasonically treated with acetone, absolute ethanol and deionized water in sequence, and then the surface of the silicon dioxide / silicon substrate was treated hydrophilically with Plasma.

[0076] The copper foil with graphene is cut into required shape, is fixed on PET with adhesive tape edge sealing, then spin-coats on graphene / Front side of copper foil; use 1000rpm to spread the glue for 10s, 3000rpm to shake the glue for 30s, put it on a hot plate at 120°C to harden the film for 10min, cut off the tape on the four sides of the copper foil, and remove the PET at the bottom; put 1mol / L ferric chloride aqueous solution on the surface for ~5min , pick up the copper foil with tweezers and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com