Gas mixing top tray assembly of MOCVD equipment and reaction device

A top-plate and gas-mixing technology, which is applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of lowering process gas temperature, insufficient process gas mixing, and insufficient cooling, etc., to increase the thickness of the film Quality and uniformity, improved heat exchange efficiency, effect of high cooling water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

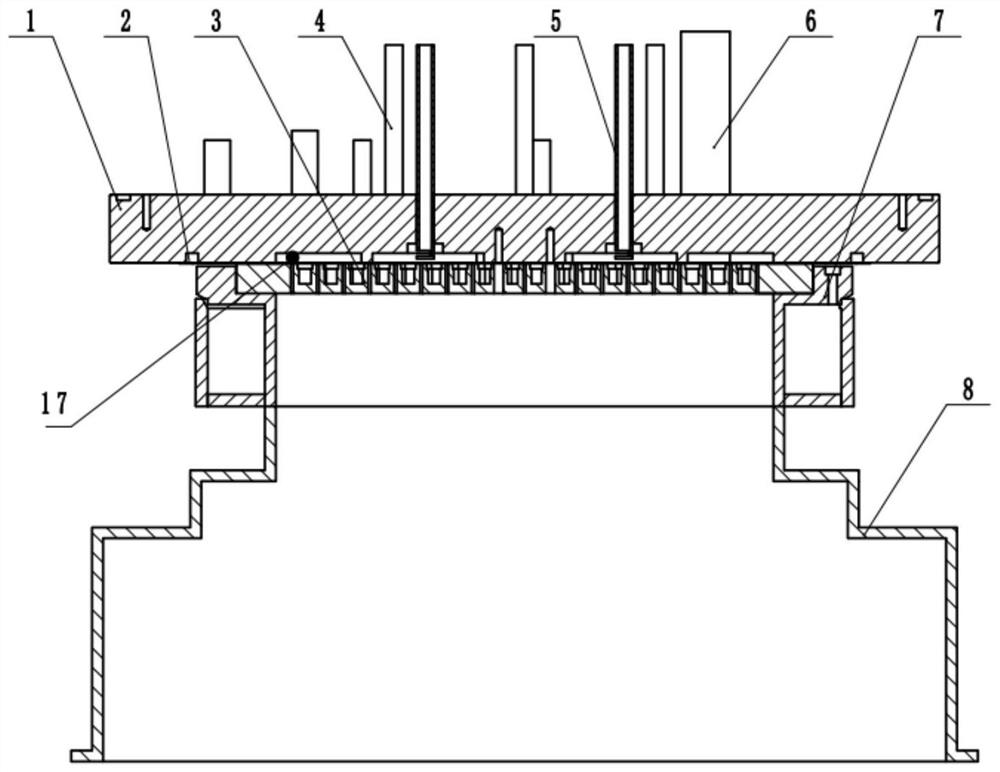

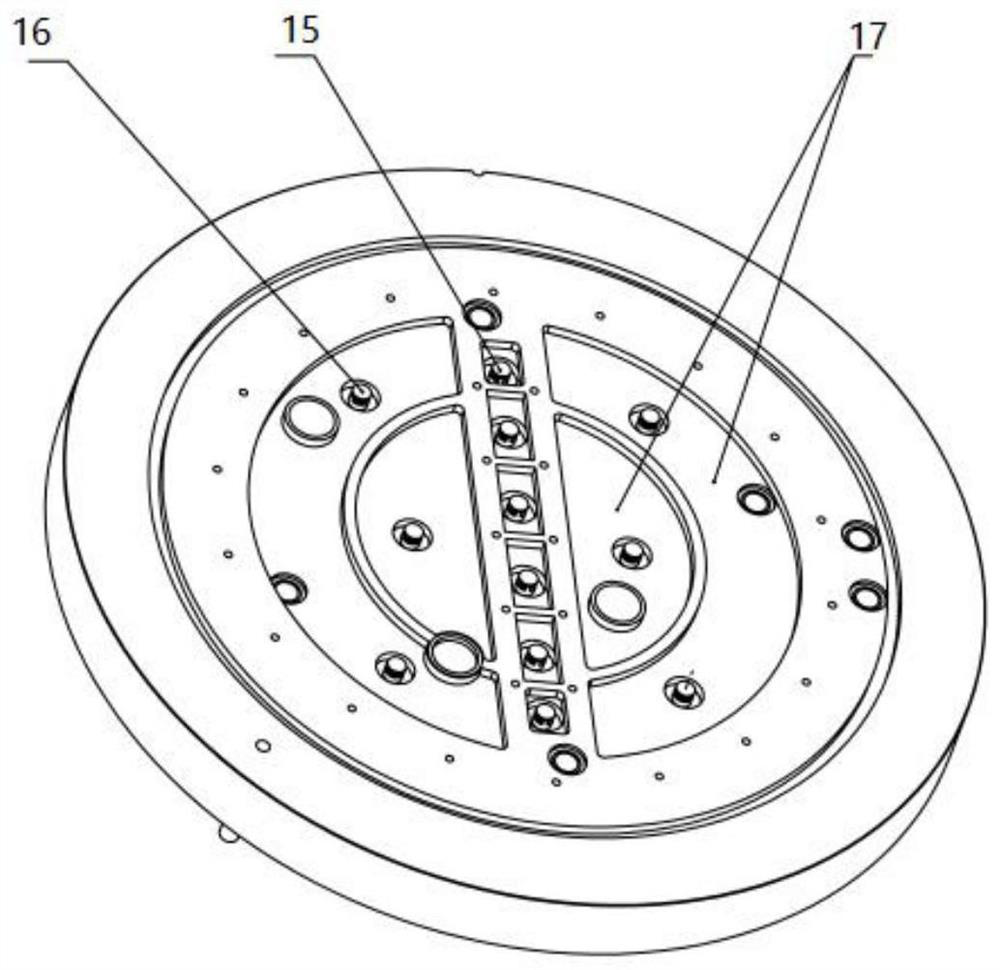

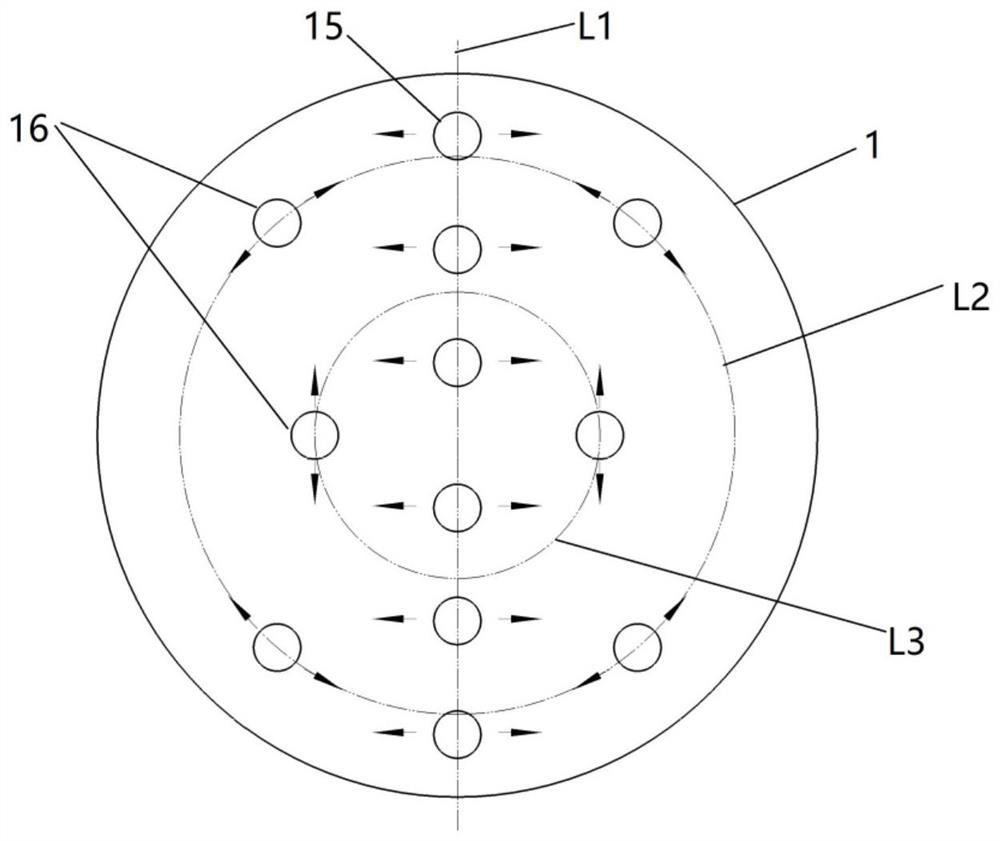

[0043] see Figure 1-5 , a MOCVD equipment gas mixing top plate assembly, comprising: a top plate 1, a gas uniform net 2 and a gas uniform water cooling plate 3; the gas uniform net 2 is arranged between the top plate 1 and the gas uniform water cooling plate 3; A mixing cavity 17 is formed between the top plate 1 and the air uniform net 2, see image 3 As shown, the top of the top plate 1 is provided with a first air intake pipeline 4 and a second air intake pipeline 5 communicating with the mixing cavity 17; Cavity, the lower surface of the gas uniform net 2 is in direct contact with the upper surface of the gas uniform water cooling plate 3; the upper surface of the gas uniform water cooling plate is covered with a plurality of water channels arranged in parallel, and the water channels are connected end to end to form a water cooling tank. And the waterway gap is full of uniform pores, such as Figure 5 shown.

[0044] The length of each water channel here is different....

Embodiment 2

[0061] Such as Figure 6 As shown: the present invention also relates to a MOCVD reaction device, including a top plate assembly, and a rotating wafer base 10 arranged under the shroud.

[0062] The height of the rotating wafer base 10 does not exceed the height of the last step of the air guide cover.

[0063] There is a certain distance between the base and the water-cooled gas distribution plate, which can ensure that the diffused gas has a long diffusion time and further cooling.

[0064] The bottom of the base 10 is connected with the driving mechanism through the rotating shaft 9 .

[0065] The working principle of this device is as follows:

[0066] refer to Figure 1-2 , the first gas MO source in the process gas enters the top plate of the MOCVD equipment system through the first gas pipeline 4 , and diffuses to the mixing cavity 17 through the first gas pipeline shower head in the top plate. The second gas N2 in the process gas diffuses to the mixing cavity 17 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com