Growth method for improving interface quality of AlGaN/AlN multi-quantum well

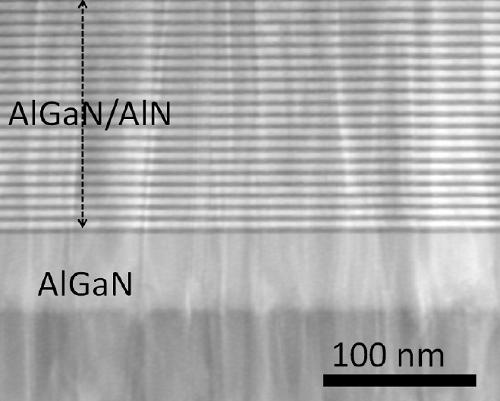

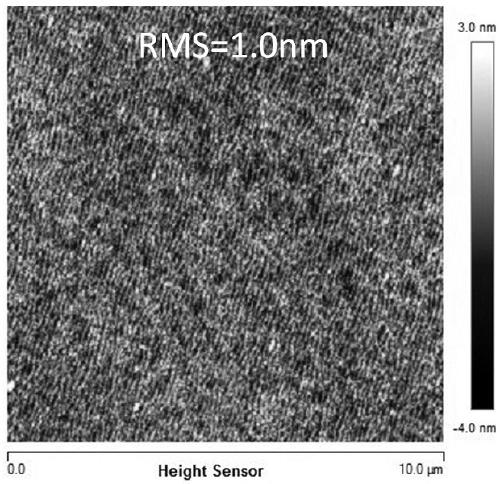

A technology of multiple quantum wells and interface quality, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced quantum efficiency, large surface undulations, blurred interfaces, etc., and achieves low defect density, smooth surface, and reduced heating effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention provides a growth method for improving the interface quality of AlGaN / AlN multiple quantum wells, comprising the following steps:

[0026] 1) Select a (0001) surface sapphire substrate, transfer it into the MOCVD system, and grow the nucleation layer, buffer layer, and n-type doped layer in sequence. The nucleation layer is an AlN film with a thickness of 20nm; the buffer layer is an AlN film with a thickness of 1000nm; the n-type doped layer is an AlGaN film with an aluminum composition of 0.6, a thickness of 2500nm, and a doping concentration of 2E19cm 3 .

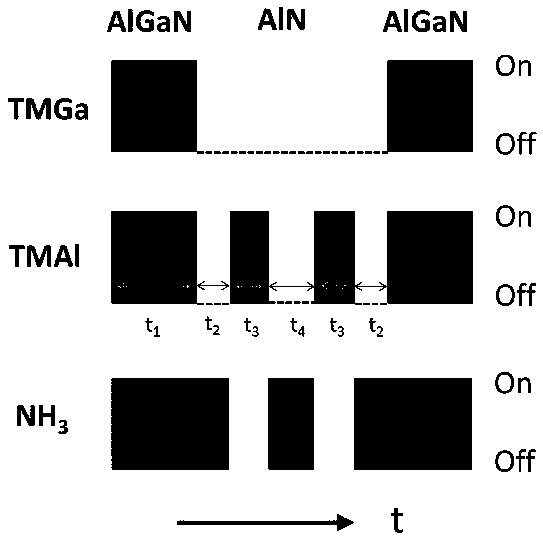

[0027] 2) Carry out the growth of the quantum barrier. The quantum barrier is an AlN layer, the source of group III is TMAl, and the source of group V is high-purity NH 3 , TMAl, NH 3 Alternately feed into the reaction chamber, 4 alternate cycles, TMAl feed time is 6s, NH 3 The penetration time is 6s, the V / III ratio (the molar ratio of the III source to the V source) is 500, the growth t...

Embodiment 2

[0035] The present invention provides a growth method for improving the interface quality of AlGaN / AlN multiple quantum wells, comprising the following steps:

[0036] 1) Select a (0001) surface sapphire substrate, transfer it into the MOCVD system, and grow the nucleation layer, buffer layer, and n-type doped layer in sequence. The nucleation layer is an AlN film with a thickness of 100nm; the buffer layer is an AlGaN film with an aluminum composition of 0.5 and a thickness of 2500nm; the n-type doped layer is an AlGaN film with an aluminum composition of 0.4 and a thickness of 1000nm with a doping concentration of 5E17cm 3 .

[0037] 2) Carry out the growth of the quantum barrier. The quantum barrier is an AlN layer, the source of group III is TMAl, and the source of group V is high-purity NH 3 , TMAl, NH 3 Alternately feed into the reaction chamber, 20 alternate cycles, TMAl feed time is 2s, NH 3 The penetration time is 2s, the V / III ratio (the molar ratio of the III sour...

Embodiment 3

[0045] The present invention provides a growth method for improving the interface quality of AlGaN / AlN multiple quantum wells, comprising the following steps:

[0046] 1) Select a (0001) surface sapphire substrate, transfer it into the MOCVD system, and grow the nucleation layer, buffer layer, and n-type doped layer in sequence. The nucleation layer is an AlN film with a thickness of 50nm; the buffer layer is an AlN film with a thickness of 1500nm; the n-type doped layer is an AlGaN film with an aluminum composition of 0.4, a thickness of 2500nm, and a doping concentration of 1E19cm 3 .

[0047] 2) Carry out the growth of the quantum barrier. The quantum barrier is an AlN layer, the source of group III is TMAl, and the source of group V is high-purity NH 3 , TMAl, NH 3 Alternately feed into the reaction chamber, 2 alternate cycles, TMAl feed time is 6s, NH 3 The penetration time is 6s, the V / III ratio (the molar ratio of the III source to the V source) is 500, the growth t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com