Doped high-voltage positive electrode material and preparation methods thereof

A positive electrode material, high voltage technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of positive electrode material capacity loss, limited battery performance improvement, complex sintering process, etc., to achieve improved capacity retention, excellent cycle stability, Effect of reducing oxygen deficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

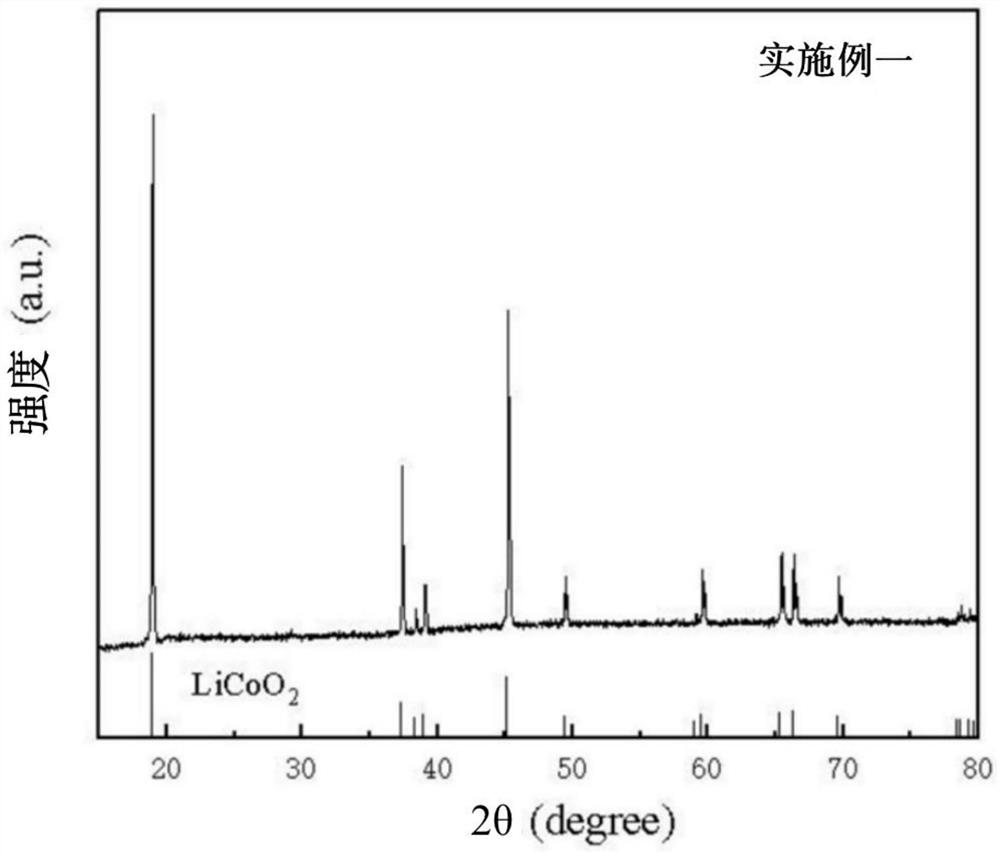

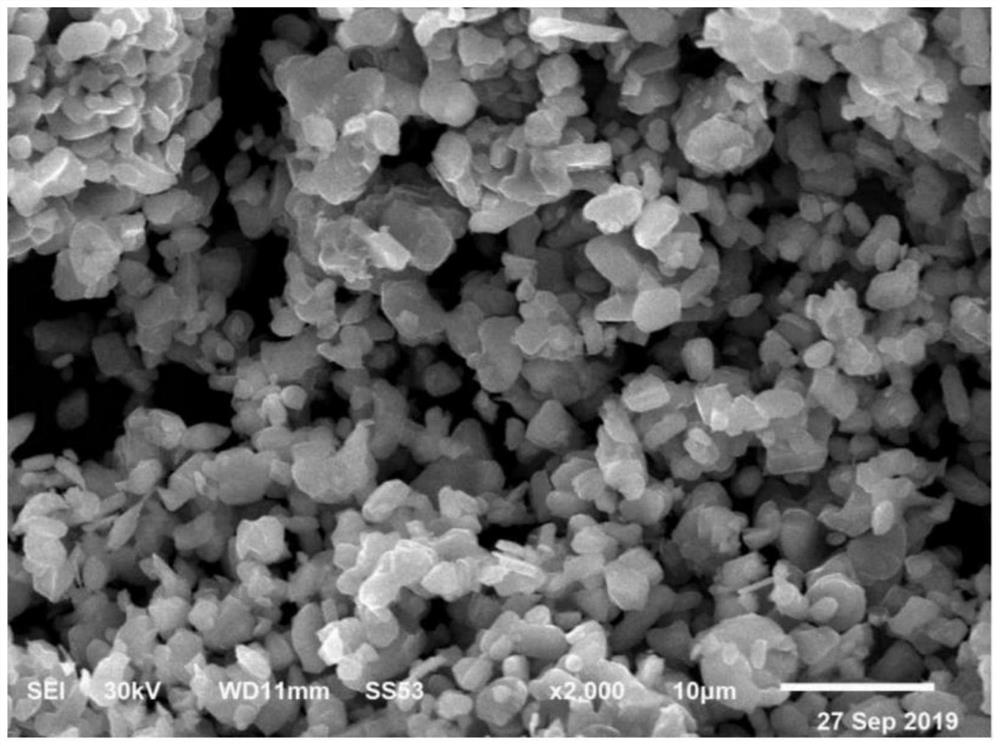

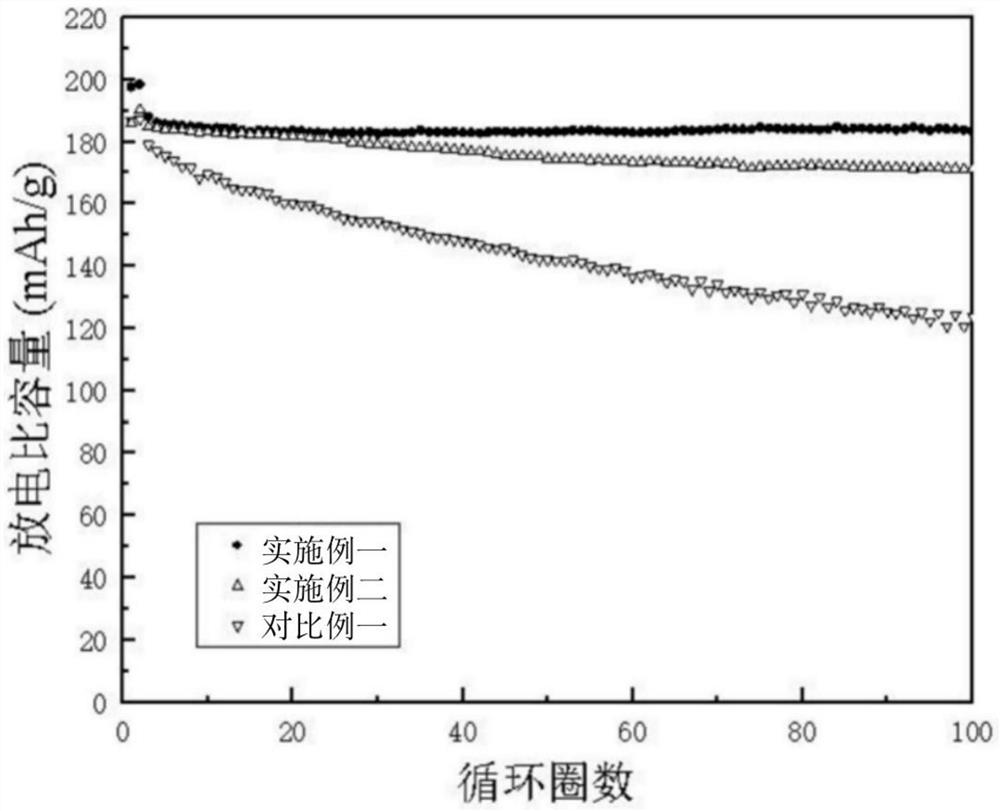

Embodiment 1

[0049] The preparation method of the doped high-voltage lithium cobalt oxide positive electrode material provided in the first embodiment includes the following steps:

[0050] 1) Weigh 36g cobalt sulfate heptahydrate, dissolve it in deionized water, prepare a cobalt sulfate solution with a concentration of 15wt%, and add 176g of sodium carbonate solution with a concentration of 8wt% (which contains 0.14g oxalic acid) under stirring in a water bath at 55°C. Sodium), and stirred for 2h, let stand, filter, wash, and vacuum dry at 110°C to obtain the precursor;

[0051] 2) Calcining the precursor obtained in step 1) in an air atmosphere at 700°C for 3 hours to obtain tricobalt tetroxide;

[0052] 3) Weigh the obtained cobalt tetroxide, lithium carbonate, zinc oxide, yttrium carbonate and terbium carbonate according to the molar ratio of Co, Li, Zn, Y, Tb as 1:1.05:0.005:0.0005:0.005, mix them uniformly, and then mix the obtained mixture Put it into a muffle furnace, calcinate at...

Embodiment 2

[0055] The preparation method of the doped high-voltage lithium cobalt oxide positive electrode material provided in the second embodiment includes the following steps:

[0056] 1) Weigh 36g cobalt sulfate heptahydrate, dissolve it in deionized water, prepare a cobalt sulfate solution with a concentration of 15wt%, and add 176g of sodium carbonate solution with a concentration of 8wt% (which contains 0.14g oxalic acid) under stirring in a water bath at 55°C. Sodium), and stirred for 2h, let stand, filter, wash, and vacuum dry at 110°C to obtain the precursor;

[0057] 2) Calcining the precursor obtained in step 1) in an air atmosphere at 700°C for 3 hours to obtain tricobalt tetroxide;

[0058] 3) Weigh the obtained cobalt tetroxide, lithium carbonate, zinc oxide, yttrium carbonate and terbium carbonate according to the molar ratio of Co, Li, Zn, Y, Tb as 1:1.05:0.002:0.0005:0.005, mix them uniformly, and then mix the obtained mixture Put it into a muffle furnace, calcinate a...

Embodiment 3

[0060] The preparation method of the doped high-voltage lithium cobalt oxide positive electrode material provided in the third embodiment includes the following steps:

[0061] 1) Weigh 36g cobalt sulfate heptahydrate, dissolve it in deionized water, prepare a cobalt sulfate solution with a concentration of 15wt%, and add 176g of sodium carbonate solution with a concentration of 8wt% (which contains 0.14g oxalic acid) under stirring in a water bath at 55°C. Sodium), and stirred for 2h, let stand, filter, wash, and vacuum dry at 110°C to obtain the precursor;

[0062] 2) Calcining the precursor obtained in step 1) in an air atmosphere at 700°C for 3 hours to obtain tricobalt tetroxide;

[0063] 3) Weigh the obtained cobalt tetroxide, lithium carbonate, zinc oxide, yttrium carbonate and terbium carbonate according to the molar ratio of Co, Li, Zn, Y, Tb as 1:1.05:0.01:0.01:0.01, mix them uniformly, and then mix the obtained mixture Put it into a muffle furnace, calcinate at a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com