High-performance renewable corneal material, reparation method and application thereof

A regenerative, high-performance technology, applied in the field of medical devices, can solve the problems of graft dissolution and long healing time, shortage of donor cornea, scarcity of cornea sources, etc., to achieve the function of promoting wound healing, good degradation resistance and biological Good compatibility and product reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

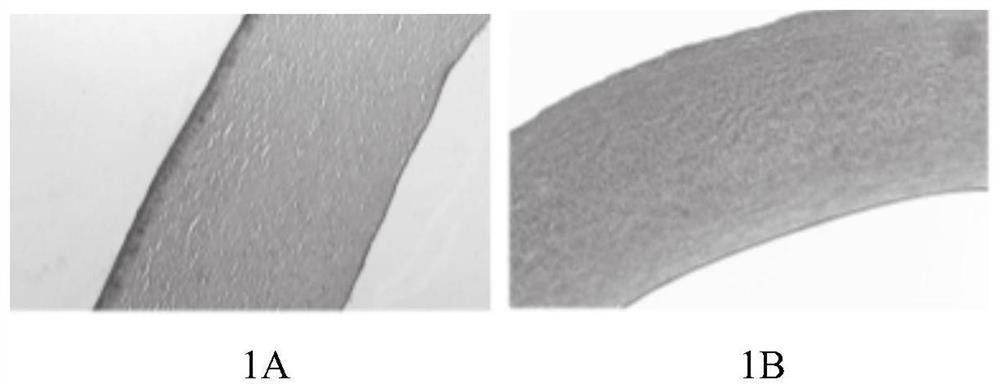

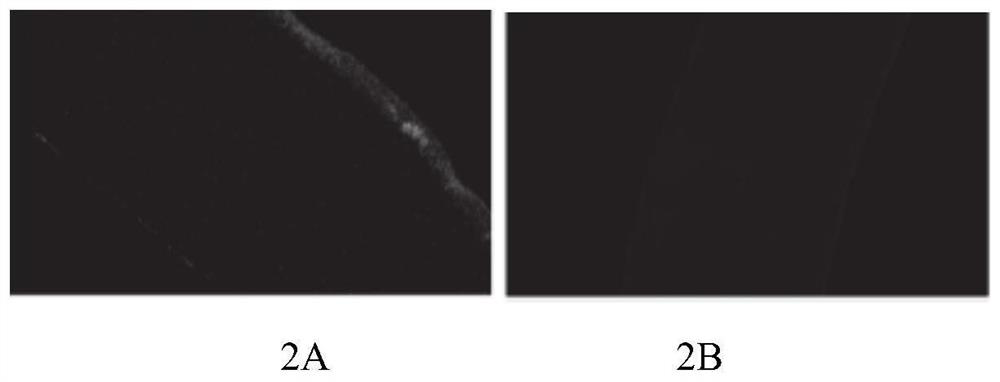

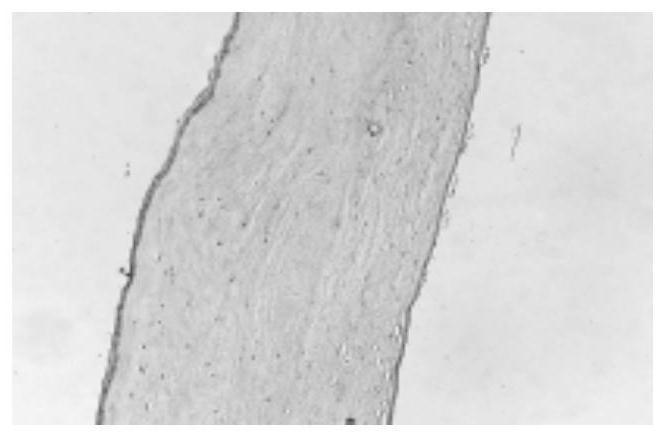

[0033] In a first aspect, the present invention provides a method for preparing a high-performance regenerative corneal material, the method comprising: performing a preliminary mild decellularization, washing, and cleaning of fresh human or animal eyeball corneal slices cut under aseptic conditions. Remove the decellularization agent, supplement glycosaminoglycan cross-linking, follow up multiple times of thorough decellularization, wash off the decellularization agent again, seal up the preservation solution, and sterilize.

[0034] Wherein, the method of cutting out the corneal stroma of a fresh animal or human eyeball under aseptic conditions includes first soaking the human or fresh animal eyeball with alcohol or a solution containing tobramycin, and then cutting out the corneal stroma under aseptic conditions tablet; the volume percentage concentration of the alcohol is preferably 70%-80%, the concentration of the tobramycin is preferably 30000-50000U / L; the animal is pre...

Embodiment 1

[0048] Take the eyeballs of pigs that have just been killed in the slaughterhouse, rinse them with 75% alcohol until the surface of the eyeballs is free of blood stains, then soak them in 40000U / L tobramycin solution and bring them back;

[0049] Take out the pig’s eyeball in a sterile room, rinse the entire eyeball with 0.9% normal saline, then cut off the fascia muscles around the eyeball, then rinse the entire eyeball with sterile PBS, and finally rinse the entire eyeball with 0.9% normal saline eyeball;

[0050] The cornea was directly drilled from the eyeball with a 5 mm diameter trephine, and the material was cut under a microscope to obtain a corneal material with a thickness of 200 μm that only contained Bowman’s layer and part of the stroma; Shaking treatment at room temperature for a certain period of time, so that the corneal epithelial cell layer and endothelial cell layer are shed and some stromal cells are lysed and killed; wherein, the decellularization agent so...

Embodiment 2

[0061] Take the eyeballs of cattle that have just been executed in the slaughterhouse, rinse them with 75% alcohol until the surface of the eyeballs is free of blood stains, then soak them in 40000U / L tobramycin solution and bring them back;

[0062] Take out the bull’s eyeball in a sterile room, rinse the whole eyeball with 0.9% normal saline, then cut off the fascia muscles around the eyeball, then wash the whole eyeball with sterile PBS, and finally wash the whole eyeball with 0.9% normal saline eyeball;

[0063] The cornea was directly drilled from the eyeball with an 8 mm diameter trephine, and the material was cut under a microscope to obtain a material with a thickness of 400 μm that only contained Bowman's layer and part of the stroma; Shaking treatment for a certain period of time, so that the corneal epithelial cell layer and endothelial cell layer are shed and some stromal cells are lysed and killed; wherein, the decellularization agent solution is 1.5% w / v sodium d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com