Method for removing oxide layer on surface of golden finger

A technology of surface oxidation and gold finger, which is applied in the field of gold finger treatment, can solve problems such as limited effect, product damage, and inability to remove the surface oxide layer, so as to achieve the effects of improving service life, high removal efficiency, and increasing anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

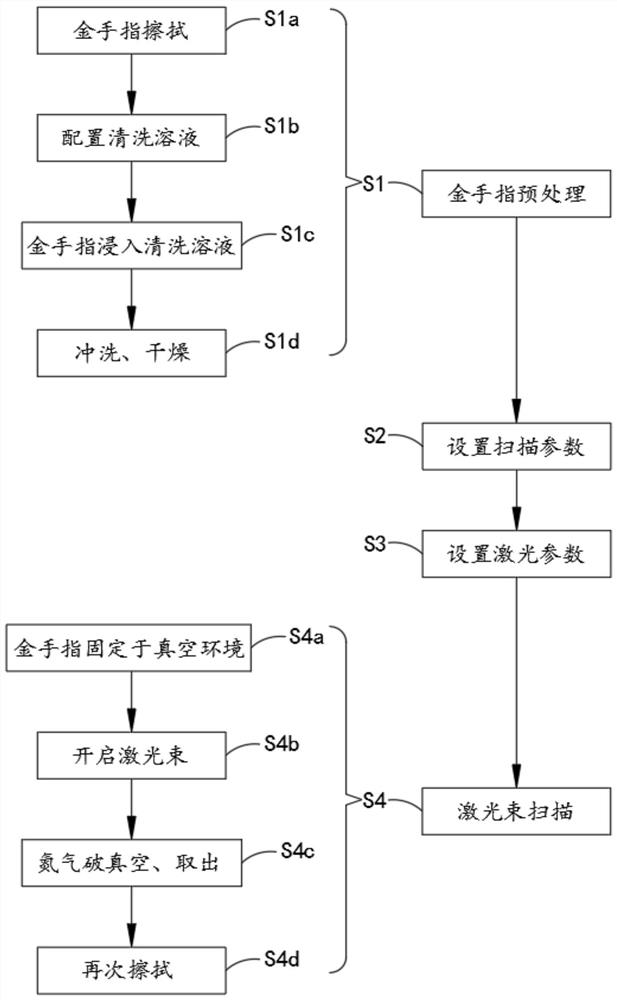

[0038] An embodiment of the present invention provides a method for removing an oxide layer on the surface of a gold finger, including:

[0039] S1. Perform preprocessing on the gold fingers to be cleared, including the following sub-steps:

[0040] S1a, using ethanol to wipe the gold finger to be removed;

[0041] S1b, using hydrofluoric acid, ammonium fluoride, and water to prepare a cleaning solution in a weight ratio of 0.5:2:20;

[0042] S1c, immerse the golden finger in the cleaning solution for a preset time, and the preset time is 10 seconds;

[0043] S1d, washing the gold finger with pure water, and drying the gold finger;

[0044] S2, setting scanning parameters according to the length, width and position distribution of the golden finger;

[0045] S3. Set the laser parameters according to the distribution of the oxide layer, the laser parameters include: laser wavelength 1064nm, laser energy density 50mJ / cm 2 , scanning rate 0.1mm / s, scanning frequency 1 time; ...

Embodiment 2

[0052] An embodiment of the present invention provides a method for removing an oxide layer on the surface of a gold finger, including:

[0053] S1. Perform preprocessing on the gold fingers to be cleared, including the following sub-steps:

[0054] S1a, using ethanol to wipe the gold finger to be removed;

[0055] S1b, using hydrofluoric acid, ammonium fluoride, and water to prepare a cleaning solution in a weight ratio of 3:5:40;

[0056] S1c, immersing the golden finger in the cleaning solution for a preset time, the preset time is 60 seconds;

[0057] S1d, washing the gold finger with pure water, and drying the gold finger;

[0058] S2, setting scanning parameters according to the length, width and position distribution of the golden finger;

[0059] S3. Set the laser parameters according to the distribution of the oxide layer, the laser parameters include: laser wavelength 1064nm, laser energy density 200mJ / cm 2 , scanning rate 2mm / s, scanning frequency 6 times;

[0...

Embodiment 3

[0066] An embodiment of the present invention provides a method for removing an oxide layer on the surface of a gold finger, including:

[0067] S1. Perform preprocessing on the gold fingers to be cleared, including the following sub-steps:

[0068] S1a, using ethanol to wipe the gold finger to be removed;

[0069] S1b, using hydrofluoric acid (purity 40%), ammonium fluoride (purity 96%), and water to prepare a cleaning solution in a weight ratio of 1:3:25, stir evenly during the preparation process, and then let stand for 20 minutes;

[0070] S1c, immerse the gold finger in the cleaning solution for a preset time, the preset time is 30 seconds;

[0071] S1d, washing the gold finger with pure water, and drying the gold finger;

[0072] S2, setting scanning parameters according to the length, width and position distribution of the golden finger;

[0073] S3. Set the laser parameters according to the distribution of the oxide layer. The laser parameters include: laser wavelengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com