Method for preparing diethoxymethane by solid superacid catalysis

A technology of diethoxymethane and solid superacid, which is applied in chemical instruments and methods, preparation of ethers, and preparation of ethers by exchanging organic parts, etc., can solve problems such as poor selectivity, high equipment cost, and poor catalyst stability, and achieve industrialization Production, good recyclability, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

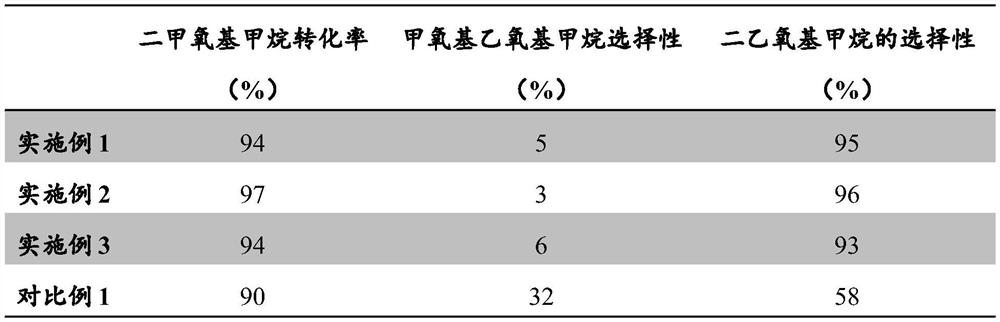

Examples

Embodiment 1

[0029] S1, the active substance of the solid superacid catalyst is H2SO4, and the carrier is SnO 2 -TiO 2 .

[0030] Described H2SO4 / SnO2-TiO solid superacid catalyst preparation method is as follows:

[0031] 1) Evenly mix 200g of tin hydroxide and 250gmol of titanium dioxide powder, 130g of porogen, 35g of binder and 103g of scallop powder, extrude, put into a muffle furnace and bake at 800°C for 5 hours to obtain SnO2- TiO2;

[0032] 2) Take a 0.8mol / L sulfuric acid solution and impregnate it into the channel prepared in step 1) three times in an ultrasonic environment, and the ultrasonic immersion time is 2 hours;

[0033] 3) After the impregnated catalyst precursor was dried in an oven at 100°C for 3 hours, it was put into a muffle furnace and baked at 500°C for 2 hours to prepare a H2SO4 / SnO2-TiO2 solid superacid catalyst.

[0034] S2, using ethanol and dimethoxymethane as raw materials, using the solid superacid prepared in step S1 as a catalyst, first put 1mol of d...

Embodiment 2

[0036] S1, the active substance of the solid superacid catalyst is H2SO4, and the carrier is SnO 2 -TiO 2 .

[0037]Described H2SO4 / SnO2-TiO solid superacid catalyst preparation method is as follows:

[0038] 1) Evenly mix 200g of tin hydroxide and 250gmol of titanium dioxide powder, 130g of porogen, 35g of binder and 103g of scallop powder, extrude, put into a muffle furnace and bake at 800°C for 5 hours to obtain SnO2- TiO2;

[0039] 2) Take a 0.3mol / L sulfuric acid solution and impregnate it into the channel prepared in step 1) twice in an ultrasonic environment, and the ultrasonic immersion time for each time is 5 hours;

[0040] 3) After the impregnated catalyst precursor was dried in an oven at 100°C for 5 hours, it was put into a muffle furnace and baked at 500°C for 3 hours to prepare a H2SO4 / SnO2-TiO2 solid superacid catalyst.

[0041] S2, using ethanol and dimethoxymethane as raw materials, using the solid superacid prepared in step S1 as a catalyst, first put 1m...

Embodiment 3

[0043] S1, the active substance of the solid superacid catalyst is H2SO4, and the carrier is SnO 2 -TiO 2 .

[0044] Described H2SO4 / SnO2-TiO solid superacid catalyst preparation method is as follows:

[0045] 1) Evenly mix 200g of tin hydroxide and 250gmol of titanium dioxide powder, 130g of porogen, 35g of binder and 103g of scallop powder, extrude, put into a muffle furnace and bake at 800°C for 5 hours to obtain SnO2- TiO2;

[0046] 2) Take a 0.3 mol / L sulfuric acid solution and impregnate it three times into the pores prepared in step 1) in an ultrasonic environment, and the ultrasonic immersion time is 4 hours;

[0047] 3) After the impregnated catalyst precursor was dried in an oven at 100°C for 3 hours, it was put into a muffle furnace and baked at 500°C for 2 hours to prepare a H2SO4 / SnO2-TiO2 solid superacid catalyst.

[0048] S2, using ethanol and dimethoxymethane as raw materials, using the solid superacid prepared in step S1 as a catalyst, first put 1mol of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com