Matrix multi-needle electrospinning equipment

An electrospinning and multi-needle technology, which is applied in textiles and papermaking, filament/thread forming, coating, etc., can solve the problems of inability to realize large-scale continuous production, low spinning efficiency, and low work efficiency. Achieve the effect of good electrostatic adsorption filtration, strong physical filtration ability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

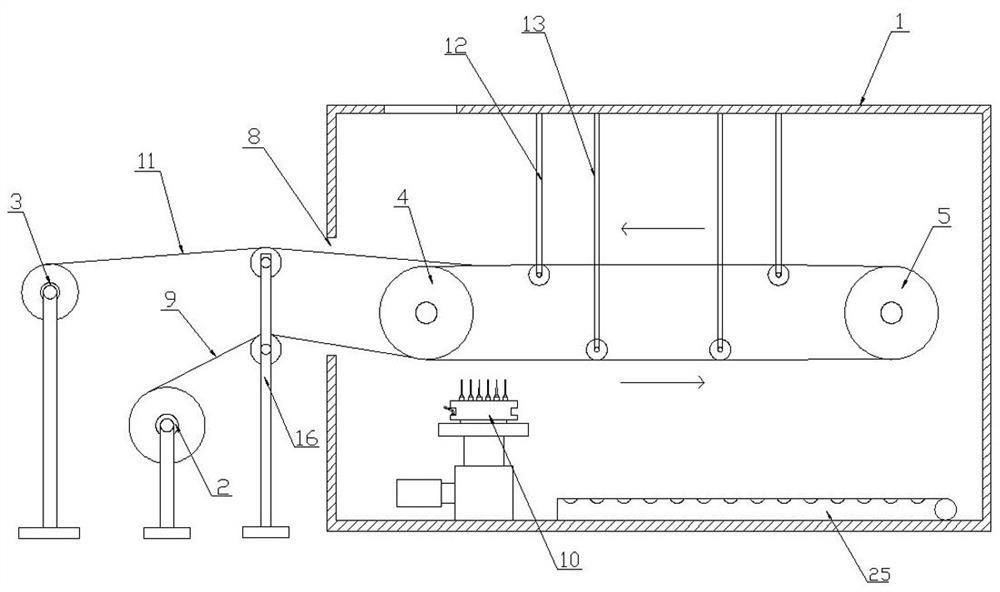

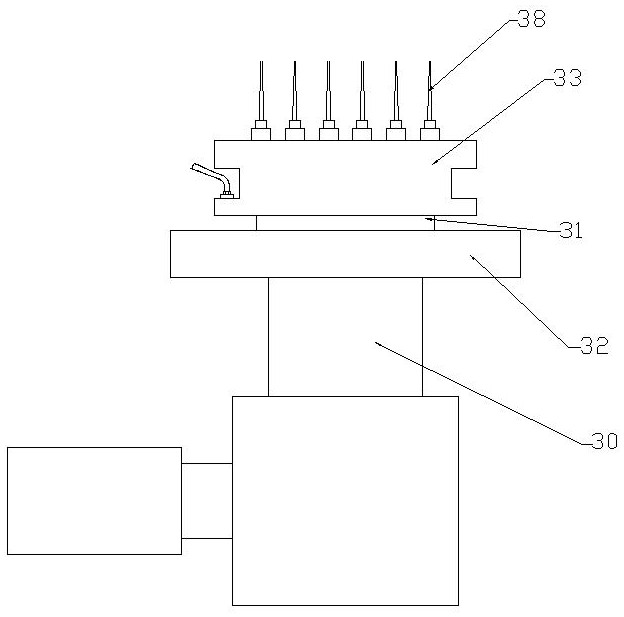

[0044] Embodiment 1: A kind of matrix multi-needle electrospinning equipment, see figure 1 , including an electrospinning chamber 1 , a feeding mechanism and a receiving mechanism arranged outside the electrospinning chamber 1 , and a transmission mechanism and a spinning mechanism 10 arranged in the electrospinning chamber 1 .

[0045] The feeding mechanism includes a feed roller 2 for installing the base material non-woven fabric 9 reel, and the receiving mechanism includes a receiving roller 3 for winding the finished material, and one end of the receiving roller 3 is connected with a receiving motor. It is used to drive the receiving roller 3 to rotate.

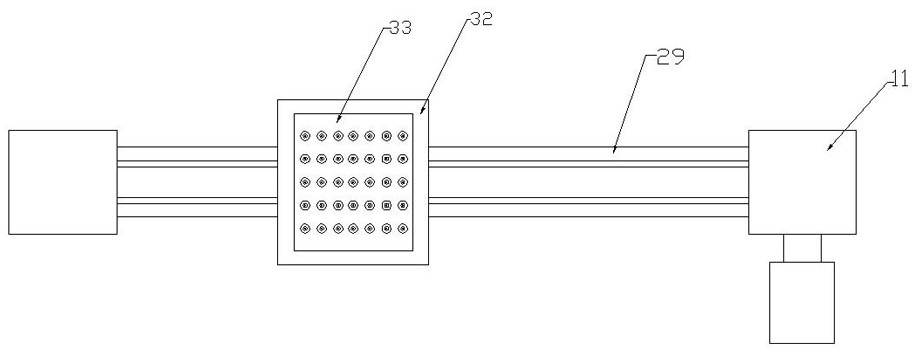

[0046] The transmission mechanism includes a driving roller 4, a driven roller 5 and a steel belt 6 set between the driving roller 4 and the driven roller 5. One end of the driving roller 4 is provided with a driving motor 7, and the output end of the driving motor 7 is connected to the driving roller 4. Coaxial connecti...

Embodiment 2

[0050] Embodiment 2: a matrix type multi-needle electrospinning equipment, the difference from Embodiment 1 is that an upper tension mechanism 12 and a lower tension mechanism 13 are also provided in the electrospinning chamber, and the upper tension mechanism 12 and The lower tensioning mechanism 13 all includes pull rods 14 vertically fixed on both sides of the top wall of the electrospinning chamber, and a tension roller 15 is installed between the two pull rods 14, see Figure 8 . The tension roller of the upper tension mechanism 12 passes between the upper steel belt and the lower steel belt, and is in close contact with the inner surface of the upper steel belt; the tension roller of the lower tension mechanism 13 passes through the upper steel belt. Pass between the belt and the lower side steel belt, and be in contact with the inner surface of the lower side steel belt; the upper tensioning mechanism 12 and the lower tensioning mechanism 13 are two groups.

[0051] An...

Embodiment 3

[0053] Embodiment 3: A matrix type multi-needle electrospinning equipment, the difference from Embodiment 2 is that a hot air pipeline is laid on the bottom surface of the electrospinning chamber 1 at the position behind the spinning mechanism, and the hot air pipe The road includes a hot-blast main pipe 24 connected to an external hot-air blower, and more than one hot-blast branch pipe 25 connected with the hot-blast main pipe 24. In this embodiment, three hot-blast branch pipes are provided, and the hot-blast branch pipe 25 is provided with cooling holes distributed equidistantly. 26. An air exhaust port 27 is provided on the top of the electrospinning chamber 1, and an exhaust fan is installed at the air exhaust port 27.

[0054] The working method of the matrix type multi-needle electrospinning equipment of the present invention is as follows: firstly, the reel of the base material non-woven fabric is installed on the feed roller, so that the movable end of the base materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com