Silicon dioxide aerogel composite thermal insulation fabric and preparation method thereof

A technology of silica and composite heat preservation, applied in the field of fabrics, can solve the problems of low refractive index, brittle and easy to crack, low thermal conductivity, etc., and achieve the effects of excellent washing resistance, strong heat insulation function, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

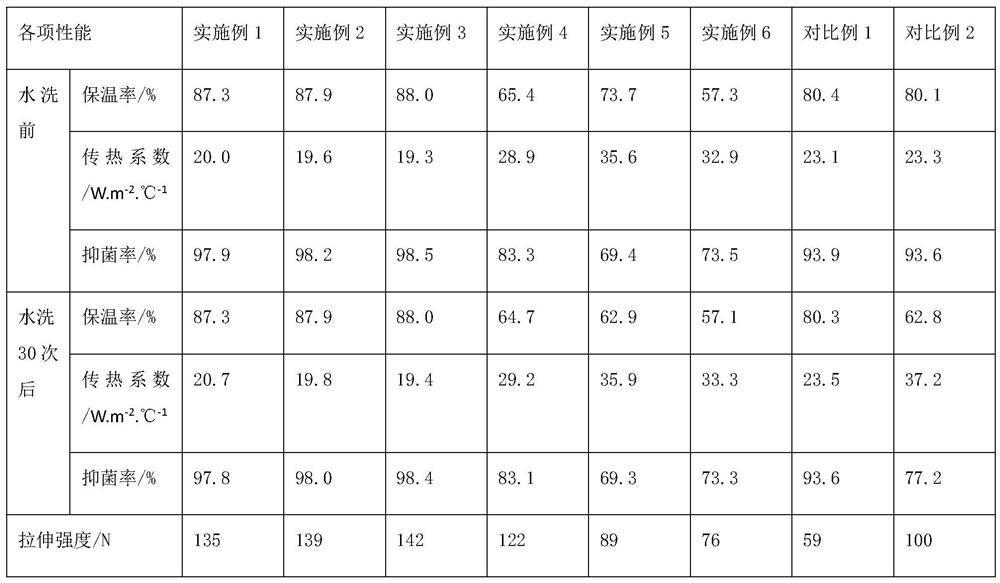

Examples

Embodiment 1

[0044] A silica airgel composite thermal insulation fabric, the mass ratio of the modified long fiber and the shell material is 1:5.

[0045] The raw material components of the modified long fiber are as follows: in parts by weight, 60 parts of modified tourmaline, 100 parts of base material mixture, 25 parts of potassium hexatitanate whisker, 20 parts of boron carbide, and 30 parts of soluble starch.

[0046] The mass ratio of the modified silica airgel to the fiber substrate is 1:10.

[0047] The raw material components of the modified tourmaline are as follows: in parts by weight, 90 parts of tourmaline, 60 parts of cationic surfactant, and 50 parts of graphene oxide.

[0048] The raw material components of the modified silica airgel are as follows: in parts by weight, 80 parts of ethyl orthosilicate, 40 parts of N,N-dimethylformamide, β-cyclodextrin / metal organic framework 20 parts of compound, 50 parts of n-hexane, 30 parts of polyethyleneimine, 28 parts of crosslinking ...

Embodiment 2

[0064] A silica airgel composite thermal insulation fabric, the mass ratio of the modified long fiber and the shell material is 2:5.

[0065] The raw material components of the modified long fiber are as follows: in parts by weight, 75 parts of modified tourmaline, 110 parts of base material mixture, 35 parts of potassium hexatitanate whisker, 30 parts of boron carbide, and 45 parts of soluble starch.

[0066] The mass ratio of the modified silica airgel to the fiber substrate is 1:5.

[0067] The raw material components of the modified tourmaline are as follows: in parts by weight, 95 parts of tourmaline, 70 parts of cationic surfactant, and 60 parts of graphene oxide.

[0068] The raw material components of the modified silica airgel are as follows: in parts by weight, 90 parts of ethyl orthosilicate, 45 parts of N,N-dimethylformamide, β-cyclodextrin / metal organic framework 25 parts of compound, 55 parts of n-hexane, 33 parts of polyethyleneimine, 30 parts of crosslinking a...

Embodiment 3

[0084] A silica airgel composite thermal insulation fabric, the mass ratio of the modified long fiber and the shell material is 3:5.

[0085] The raw material components of the modified long fiber are as follows: in parts by weight, 90 parts of modified tourmaline, 120 parts of base material mixture, 45 parts of potassium hexatitanate whisker, 40 parts of boron carbide, and 60 parts of soluble starch.

[0086] The mass ratio of the modified silica airgel to the fiber substrate is 3:10.

[0087] The raw material components of the modified tourmaline are as follows: in parts by weight, 100 parts of tourmaline, 80 parts of cationic surfactant, and 70 parts of graphene oxide.

[0088] The raw material components of the modified silica airgel are as follows: in parts by weight, 100 parts of ethyl orthosilicate, 50 parts of N,N-dimethylformamide, β-cyclodextrin / metal organic framework 30 parts of compound, 60 parts of n-hexane, 35 parts of polyethyleneimine, 32 parts of crosslinkin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com