Electrochromic material, preparation method and application thereof, and electrochromic device

A technology of electrochromic materials and electrochromic devices, applied in metal material coating technology, instruments, ion implantation plating, etc., can solve the problems of consuming device life, increased transmittance in colored state, poor memory effect, etc. problem, achieve the effect of improving the memory effect, inhibiting the self-extrusion process, and prolonging the time for maintaining low transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] In the second aspect, the present application also provides a preparation method of the aforementioned electrochromic material, for example, may include the following steps: depositing WO on the surface of the substrate by means of vacuum magnetron sputtering 3 layer, followed by WO 3 A protective layer is prepared on the surface of the layer facing away from the substrate.

[0057] In an optional embodiment, the protective layer is prepared by vacuum magnetron sputtering.

[0058] In an optional embodiment, WO in this application 3 During the vacuum magnetron sputtering process of the layer, the sputtering power can be 80-120W, such as 80W, 85W, 90W, 95W, 100W, 105W, 110W, 115W or 120W. The sputtering time may be 60-150 min, such as 60 min, 70 min, 80 min, 90 min, 100 min, 110 min, 120 min, 130 min, 140 min or 150 min, etc. Preferably, the sputtering time is 70-130 min.

[0059] It is worth noting that the inventors found that WO 3 If the vacuum magnetron sputterin...

Embodiment 1

[0078] This embodiment provides a kind of WO for electrochromic device 3 / protective layer structure thin film electrochromic layer, which uses SnO 2 As the protective layer material, the substrate is made of ITO transparent conductive glass, and the specific preparation method is as follows:

[0079] An ultra-high vacuum multi-target magnetron sputtering apparatus (JGP-560, Shenyang Scientific Instrument Development Center Co., Ltd., Chinese Academy of Sciences) was used for sputtering, and the sputtering power was 100W. First, WO with a purity of 99.99% 3 with SnO 2 The targets are respectively installed on the target head of the RF power supply; the ITO transparent conductive glass substrate is cleaned in sequence with acetone, absolute ethanol and deionized water in an ultrasonic cleaner to remove oil and dust on the surface of the substrate, and then placed in a vacuum After drying in the drying oven, take it out, install the ITO transparent conductive glass substrate ...

Embodiment 2

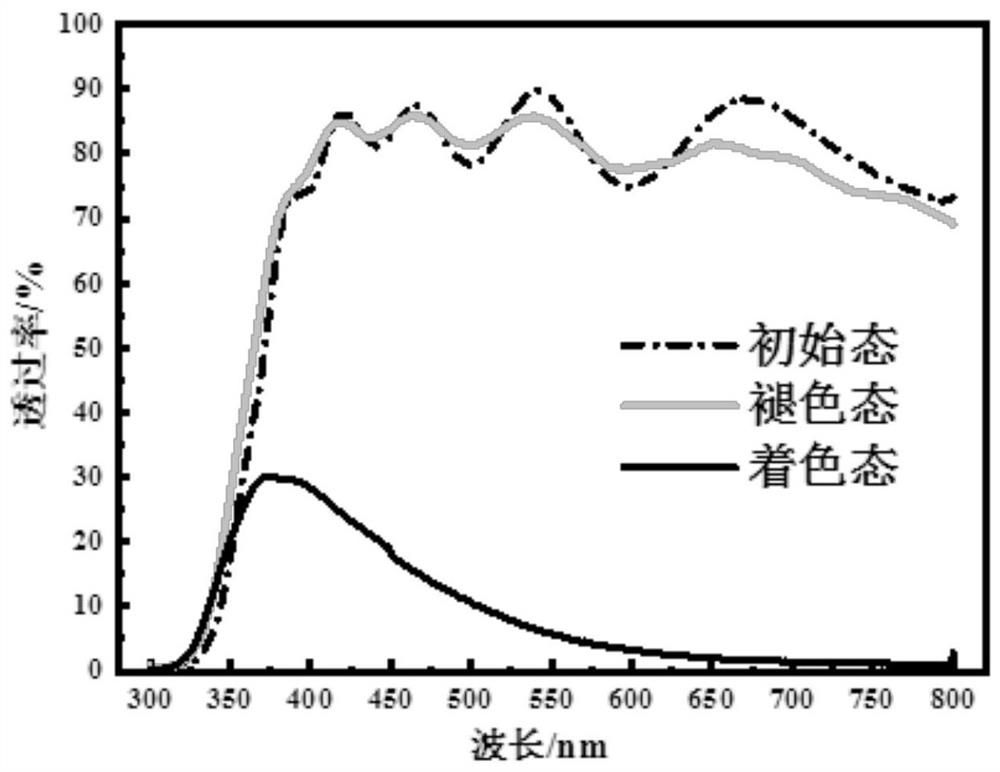

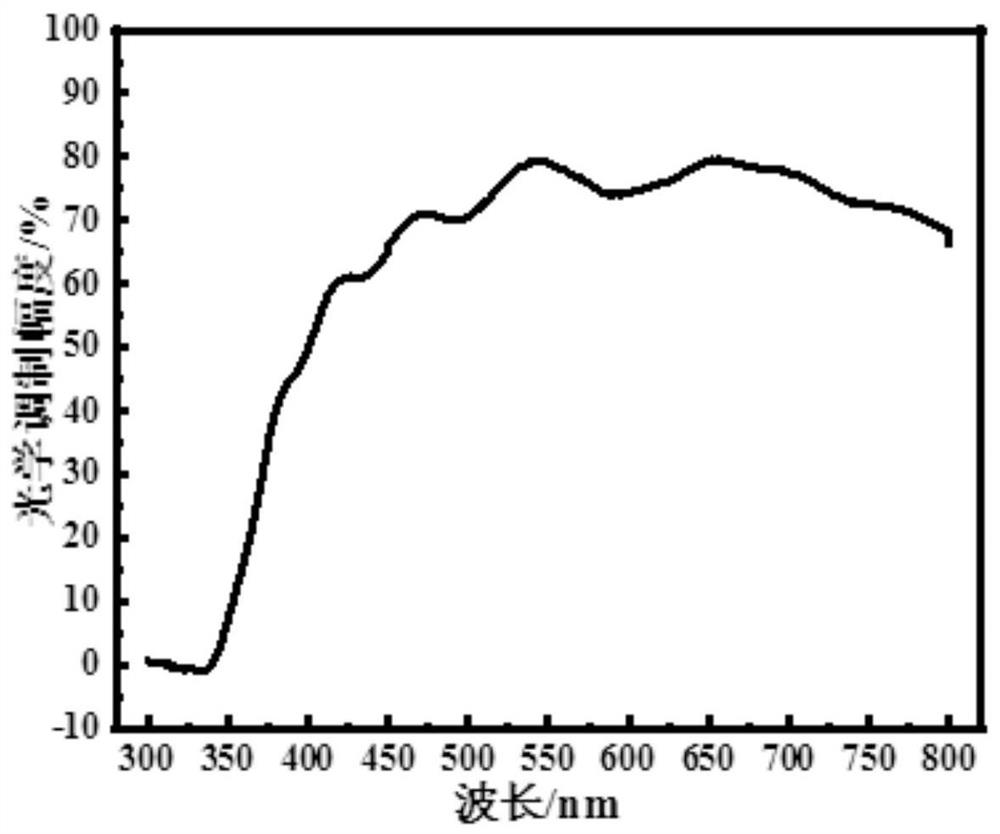

[0085] IFO / WO of this embodiment 3 / SnO 2 The preparation steps of the electrochromic thin film material are basically the same as those described in Example 1, except that the IFO conductive glass is used as the substrate, and the SnO 2 The sputtering time used for the layering of thin films was 10 min. Figure 4 WO prepared for this example 3 / SnO 2 XRD pattern of the structured film.

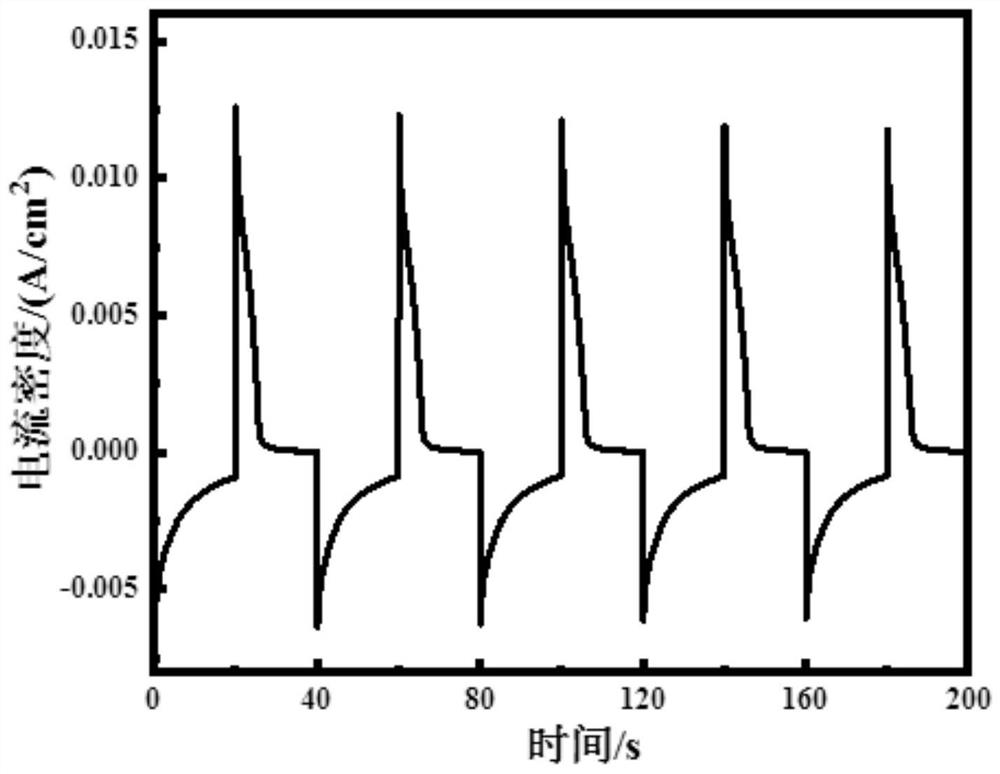

[0086] WO prepared in this example 3 / SnO 2 The cross-sectional morphology of structural thin film materials is shown in Figure 5 , as shown in the figure, the total thickness of the structured film is about 450nm, where WO 3 The thickness of the active layer is about 350nm, and the upper layer of SnO 2 The thickness of the layer is about 100 nm. At the same time, SnO can be found 2 layer and WO 3 The bonding of the layers is better, which will benefit the SnO 2 layer pair WO 3 Support and protection of active particles, thus improving long-term cycle stability. and SnO 2 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com