A way to remove h from gas 2 s and method for recovering sulfur

A sulfur and gas technology, which is applied in separation methods, gas treatment, sulfur preparation/purification, etc., can solve the problems of aggravated sulfide concentration inhomogeneity, sulfide desorption unevenness, etc., to avoid leakage risk, simple process, The effect of wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

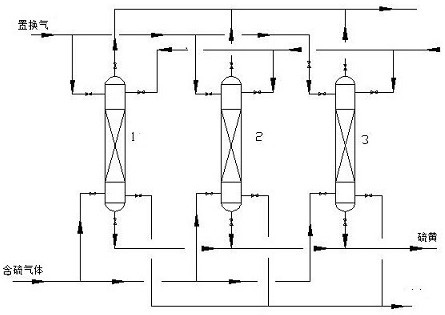

Method used

Image

Examples

Embodiment 1

[0021] Example 1: using modified 4A type molecular sieve adsorbent, containing H 2 S400mg / Nm 3 After the synthesis gas passes through the adsorption bed of the present invention, the H in it 2 S dropped to 3.6mg / Nm 3 , at 265 °C, SO was fed into the adsorbent bed 2 , the yield of sulfur was 91.2%.

Embodiment 2

[0022] Example 2: using modified Y-type molecular sieve adsorbent, containing H 2 S15%v, COS110mg / Nm 3 , Methyl mercaptan 80mg / Nm 3 After the natural gas passes through the adsorption bed of the present invention, the H 2 S dropped to 5.2mg / Nm 3 , the total sulfur dropped to 11.7 mg / Nm 3 , at 288 °C, SO was fed into the adsorbent bed 2 , the yield of sulfur was 90.3%.

Embodiment 3

[0023] Example 3: using modified 13A type molecular sieve adsorbent, containing H 2 S3.2%v, COS70mg / Nm 3 After the hydrogenation tail gas of the CLAUS unit passes through the adsorption bed of the present invention, the H 2 S dropped to 4.4mg / Nm 3 , the total sulfur dropped to 9.3 mg / Nm 3 , at 236 °C, pass SO into the adsorbent bed 2 , the yield of sulfur was 88.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com