Liquid amino acid fertilizer produced from animal protein and preparation method thereof

An amino acid and protein technology, used in animal carcass fertilizers, liquid fertilizers, organic fertilizers, etc., can solve the problems of increasing soil pests and diseases, polluting the environment, burning seedlings, etc., and achieve the effect of eliminating odor, killing viruses and harmful bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

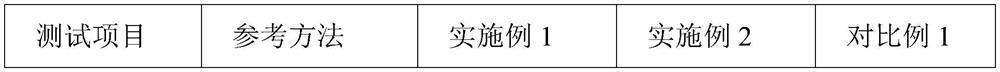

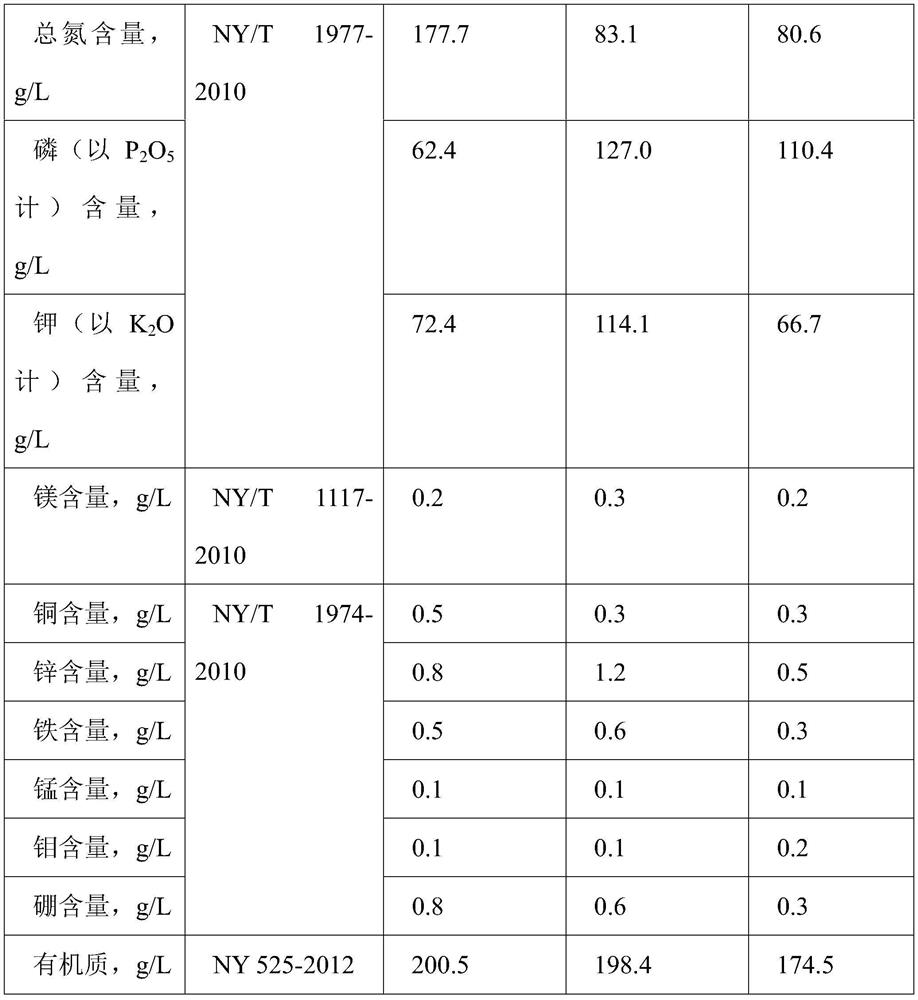

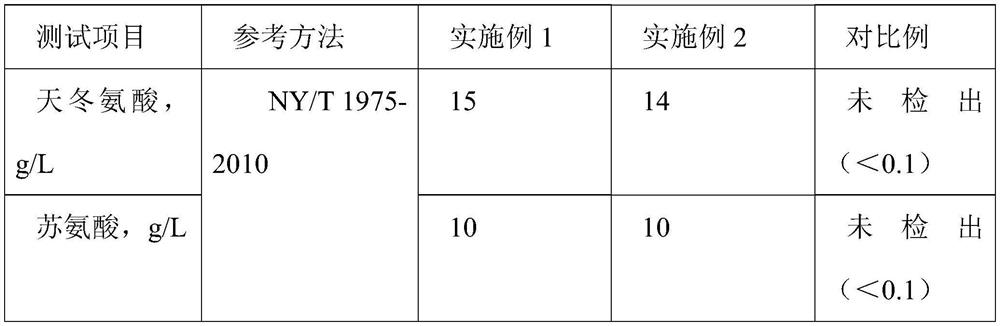

Examples

Embodiment 1

[0025] A method of utilizing animal protein to produce liquid amino acid fertilizer, comprising the following steps:

[0026] 1) Crushing 1000g of animals and / or animal waste to be processed to obtain a crushed object with a size of 3cm; in this embodiment, the raw materials to be processed specifically include but are not limited to: poultry animal carcasses, waste from slaughterhouses waste, fish, meat and poultry waste from meat and vegetable markets, aquaculture, processed fish and shrimp and waste, low-value fish and shrimp caught in the ocean, poultry and animals killed by the epidemic, and frozen fish confiscated by government law enforcement agencies.

[0027] 2) Heat and mix animals and / or animal scraps with lye at 50°C to make the pH above 13, keep warm and stir at a speed of 15rpm for 1-5 hours, hydrolyze and then stand for stratification to obtain the upper layer of oil , the hydrolyzate in the middle layer and the bottom solid, separate the grease (triglyceride) b...

Embodiment 2

[0031] A method of utilizing animal protein to produce liquid amino acid fertilizer, comprising the following steps:

[0032] 1) Crushing 1000g of animals and / or animal waste to be processed to obtain a crushed object with a size of 10cm; in this embodiment, the raw materials to be processed specifically include but are not limited to: poultry animal carcasses, waste from slaughterhouses waste, fish, meat and poultry waste from meat and vegetable markets, aquaculture, processed fish and shrimp and waste, low-value fish and shrimp caught in the ocean, poultry and animals killed by the epidemic, and frozen fish confiscated by government law enforcement agencies.

[0033] 2) Heat and mix animals and / or animal waste and lye at 90°C to make the pH 14, keep warm and stir at a speed of 15rpm for 1 hour, after hydrolysis, stand to separate layers, and stand to obtain the upper layer of oil and the middle layer of hydrolysis Liquid and bottom solids, grease (triglyceride) is separated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com