Purification method of chromatographically pure methanol

A purification method and chromatographic purification technology, applied in the field of methanol purification, can solve the problems of small absorbance, large difference, and insignificant difference in manufacturing costs, etc., and achieve the effects of reducing water content, good contact reaction, and increasing molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

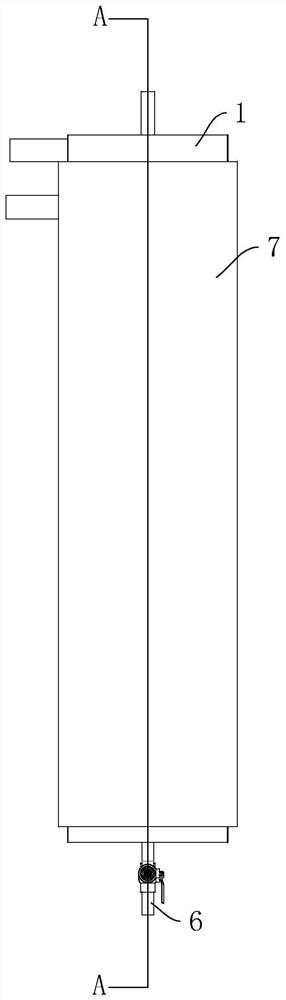

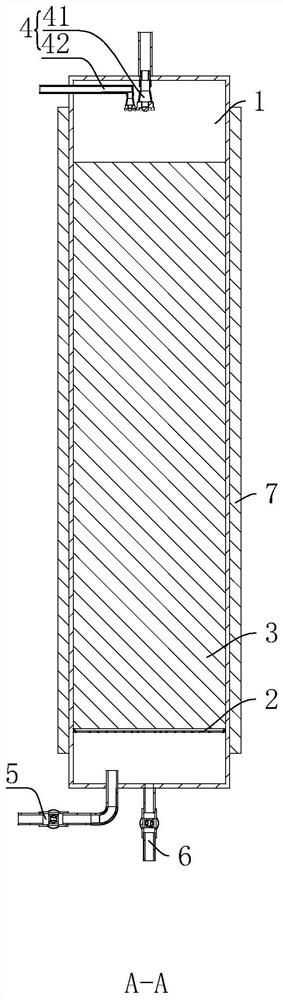

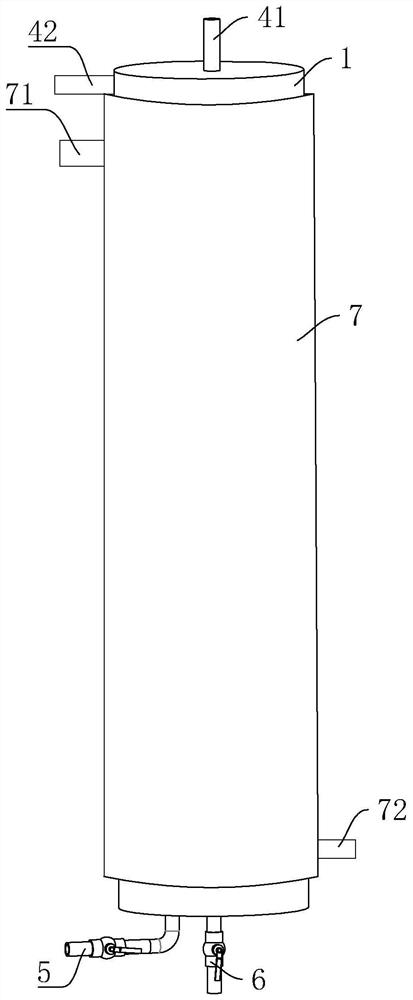

Image

Examples

Embodiment 1

[0073] A. Oxidative neutralization reaction:

[0074] S1. Select calcium oxide as a neutralizing agent, add calcium oxide to industrial methanol and mix evenly, so that the pH value of industrial methanol is 9-12, and obtain pretreated industrial methanol, wherein the volume of industrial methanol is 30L, and the volume of oxidant is The weight is 150g.

[0075] S2. Select concentrated sulfuric acid as the oxidant, and use a metering pump to add pretreated industrial methanol and concentrated sulfuric acid into the oxidation neutralization column through two liquid separators, so that the pretreated industrial methanol and concentrated sulfuric acid can be evenly distributed on the packing On, the pretreated industrial methanol and concentrated sulfuric acid are allowed to fully react while flowing downwards. When flowing to the bottom of the oxidation neutralization column, the pH value of the solution is 7, and before adding the pretreated methanol solution and concentrated ...

Embodiment 2

[0081] Embodiment 2: The difference with embodiment 1 is that the oxidizing agent in step A is hydrogen peroxide.

Embodiment 3

[0082] Embodiment 3: The difference with embodiment 1 is that the neutralizing agent in step A is sodium hydroxide.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap