A method for extracting high-purity mangiferin from mango leaves

A technology of mango leaves and mangiferin, which is applied in the field of extraction of plant functional components, can solve the problems of low solubility of mangiferin, lower extraction rate, and low extraction rate, and achieve the effects of low cost, increased yield, and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

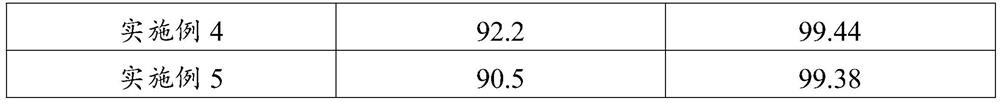

Examples

Embodiment 1

[0048] A method for extracting high-purity mangiferin from mango leaves, comprising the following steps:

[0049] 1) Take mango leaves with complete leaf shape and good elasticity, wash, drain, remove petiole, dry at 40°C low temperature, crush and pass through 80-mesh sieve, and store in dark place for later use;

[0050] 2) Mix the treated mango leaves with 75% ethanol solution at a ratio of 1:5g / mL, heat to 40°C with microwaves, and perform ultrasonic extraction twice, with extraction power of 120w and extraction time of 15min;

[0051] 3) Combine the extracts, centrifuge the extracts at 4°C and 3500r / min for 15min, and take the supernatant;

[0052] 4) The supernatant was rotary evaporated at 45°C until the volume was 1 / 5 of the original extract to obtain a concentrated extract;

[0053] 5) AB-8 type macroporous adsorption resin was used to purify the concentrated extract, the loading volume was 12BV, and after the purification was completed, it was eluted with 75% ethano...

Embodiment 2

[0057] A method for extracting high-purity mangiferin from mango leaves, comprising the following steps:

[0058] 1) Take the mango leaves with complete leaf shape and good elasticity, wash, drain, remove the petiole, dry at 40°C, pass through a 120-mesh sieve after crushing, and store in the dark for later use;

[0059] 2) Mix the treated mango leaves with 95% ethanol solution at a ratio of 1:15g / mL, heat to 60°C with microwave, and perform ultrasonic extraction 5 times respectively, with extraction power of 120w and extraction time of 45min;

[0060] 3) Combine the extracts, centrifuge the extracts at 0°C and 5000r / min for 45min, and take the supernatant;

[0061] 4) The supernatant was rotary evaporated at 60°C until the volume was 1 / 5 of the original extract to obtain a concentrated extract;

[0062] 5) AB-8 type macroporous adsorption resin was used to purify the concentrated extract, the loading volume was 9BV, and after the purification was completed, it was eluted wit...

Embodiment 3

[0066] A method for extracting high-purity mangiferin from mango leaves, comprising the following steps:

[0067] 1) Take mango leaves with complete leaf shape and good elasticity, wash, drain, remove the petiole, dry at 40°C, pass through a 100-mesh sieve after crushing, and store in the dark for later use;

[0068] 2) Mix the treated mango leaves with 80% ethanol solution at a ratio of 1:8g / mL, heat to 60°C with microwave, and perform ultrasonic extraction 5 times respectively, the extraction power is 250w, and the extraction time is 25min;

[0069] 3) Combine the extracts, centrifuge the extracts at 4°C and 4000r / min for 20min, and take the supernatant;

[0070] 4) The supernatant was rotary evaporated at 50°C until the volume was 1 / 5 of the original extract to obtain a concentrated extract;

[0071] 5) AB-8 type macroporous adsorption resin was used to purify the concentrated extract, the loading volume was 10BV, and after the purification was completed, it was eluted wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com