Trough type solar all-day heat supply system using dust particles as energy storage material

A trough-type solar energy and dust particle technology, which is applied in the field of trough-type solar all-day heating systems, can solve the problems of high operation and maintenance costs, non-universal use, and high cost, and achieve low conduction efficiency, improve heat transfer efficiency, and increase radiation heat transfer The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

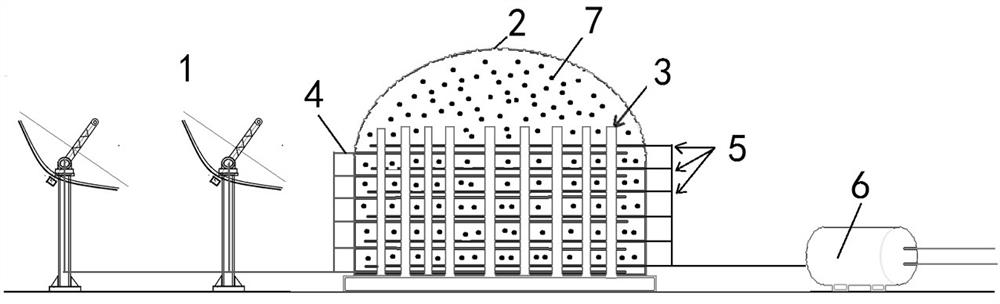

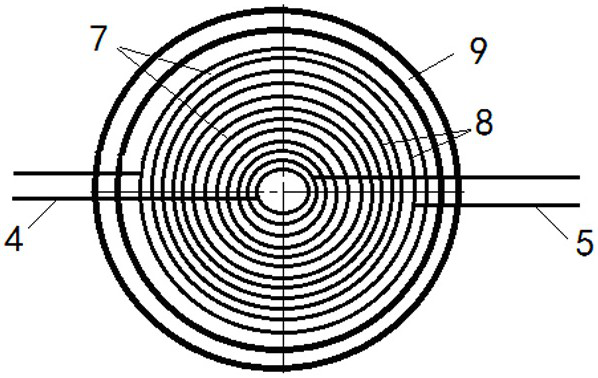

[0029] Embodiment 1, with reference to figure 1 , a trough-type solar all-day heating system using dust particles as energy storage materials mentioned in the present invention, including a trough-type solar heat collection field 1, a dust particle energy storage tank 2, a heat-conducting metal 3, a heating heat exchange tube 4, Exothermic heat exchange tube 5, heat exchanger 6, the outer wall of the cylindrical dust particle energy storage tank 2 is provided with an insulation layer 9, and the dust particle energy storage tank 2 is equipped with a heat conducting metal 3, a heating heat exchange tube 4, and a heat release The heat exchange tube 5 and the dust particles 7, the heat conduction metal 3 are arranged in multiple groups vertically, the heating heat exchange tube 4 is in contact with the heat conduction metal 3, the exothermic heat exchange tube 5 is in contact with the heat conduction metal 3, and the dust particles 7 are filled in the dust particle The inner cavit...

Embodiment 2

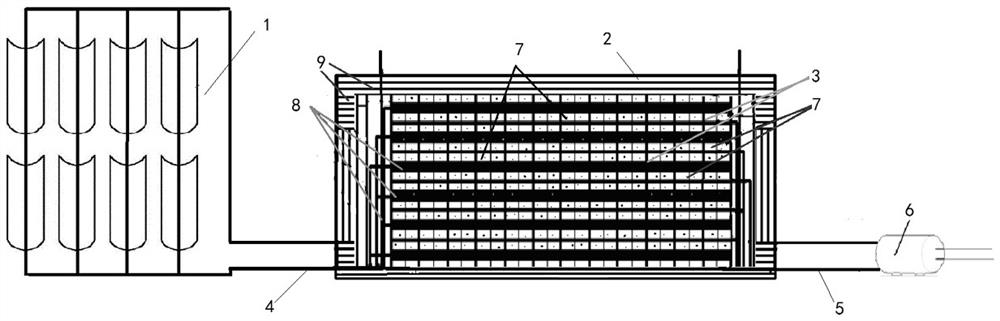

[0059] Embodiment 2, the present invention mentions a trough-type solar all-day heating system using dust particles as energy storage materials, including a trough-type solar heat collection field 1, dust particle energy storage tank 2, heat-conducting metal 3. Heating heat exchange tube 4, heat release heat exchange tube 5, heat exchanger 6, heat exchange coil 8, insulation layer 9, the outer wall of the dust particle energy storage tank 2 is provided with an insulation layer 9, and the dust particle energy storage tank 2 Install heat-conducting metal 3, heating and heat-exchanging tubes 4, exothermic heat-exchanging tubes 5, dust particles 7, and heat-exchanging coils 8. The heat-conducting metal 3 is provided with multiple groups vertically, heating and heat-exchanging tubes 4 and heat-exchanging coils 8 Contact with the heat conduction metal 3 respectively, the heat release heat exchange tube 5 is in contact with the heat conduction metal 3, and the dust particles 7 are fil...

Embodiment 3

[0062] Embodiment 3, the present invention adopts a trough solar all-day heating system that uses dust particles as energy storage materials mentioned in the present invention, including a trough solar heat collection field 1, a dust particle energy storage tank 2, a heat conduction Metal 3, heating heat exchange tube 4, heat release heat exchange tube 5, heat exchanger 6, insulation layer 9, the outer wall of the dust particle energy storage tank 2 is provided with an insulation layer 9, and the dust particle energy storage tank 2 is installed with a heat-conducting metal 3. Heating heat exchange tubes 4, exothermic heat exchange tubes 5, dust particles 7, multiple sets of heat transfer metal 3 are arranged vertically, heating heat exchange tubes 4 and heat exchange coils 8 are in contact with heat transfer metal 3 respectively, the heat release The heat exchange tube 5 is in contact with the heat-conducting metal 3, and the dust particles 7 are filled in the inner cavity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com