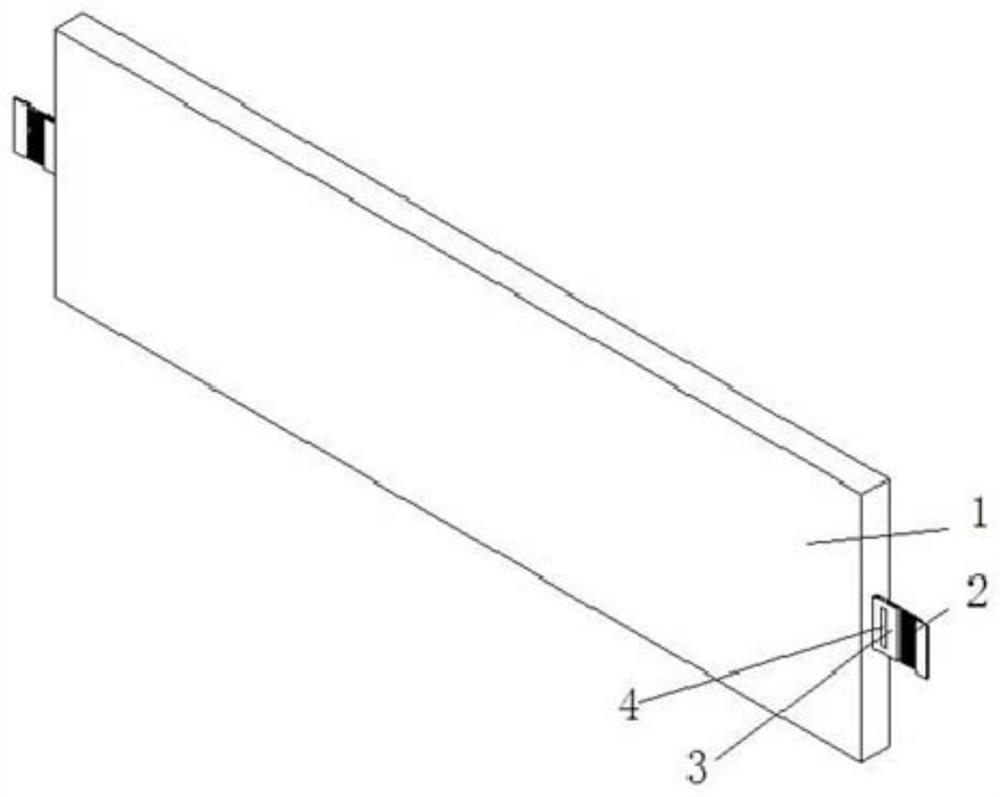

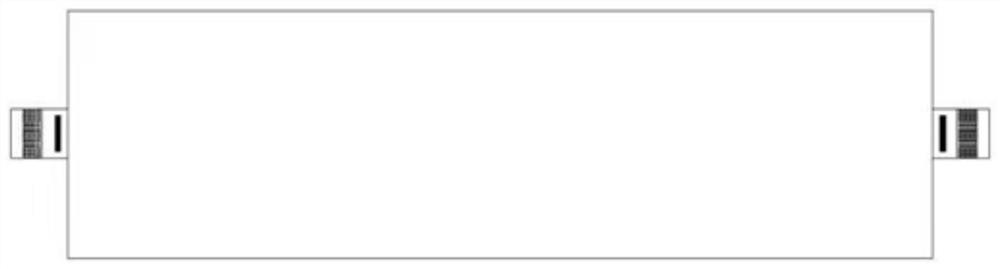

Lithium ion battery tab with gridding structure design, and preparation method thereof

A lithium-ion battery, grid technology, applied in the direction of secondary batteries, structural parts, battery pack parts, etc., can solve the problems of frequent electric vehicle safety accidents, illegal operation by users, and removal of defective batteries, and achieve a simple structure. , The effect of reducing serious accidents and facilitating welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 This example provides a method for preparing lithium-ion battery tabs, including:

[0047] Prepare the main tab:

[0048]Production of base film layer: Polymer material (PP), conductive material (graphene, D50 is 50nm), dopant (acrylic acid) are mixed according to the mass ratio of 80%, 15%, and 5%, and then uniformly drawn by melting and mixing to prepare the base film layer. film layer, the thickness of the base film layer is made according to 1mm, and the conductivity of the base film layer is 10 -8 S / m.

[0049] Fabrication of the current collector layer: the positive tab is made of aluminum, and the negative tab is made of copper. By means of magnetron sputtering, a current collector layer is plated on both sides of the base film layer. The current collector layer is on the width of the tab. as wide as the basement membrane. The two ends of the current collector layer along the direction of the current path are full-coverage designed full-coverage area...

Embodiment 2

[0053] Example 2 This example provides a method for preparing lithium-ion battery tabs, including:

[0054] Prepare the main tab:

[0055] Production of base film layer: Polymer material (PP), conductive material (graphene, D50 is 50nm), dopant (acrylic acid) are mixed according to the mass ratio of 85%, 5%, and 10%, and then uniformly drawn by melt mixing to prepare the base film layer. film layer, the thickness of the base film layer is made according to 0.8mm, and the conductivity of the base film layer is 10 -12 S / m.

[0056] Fabrication of the current collector layer: the positive tab is made of aluminum, and the negative tab is made of copper. By means of magnetron sputtering, a current collector layer is plated on both sides of the base film layer. The current collector layer is on the width of the tab. as wide as the basement membrane. The two ends of the current collector layer along the direction of the current path are full-coverage designed full-coverage areas, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com