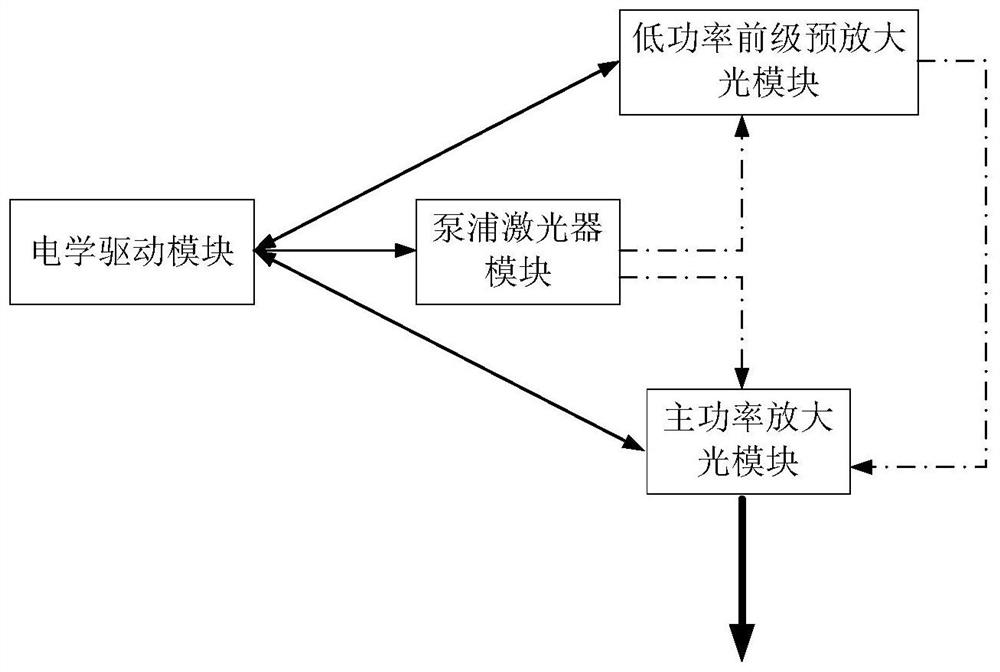

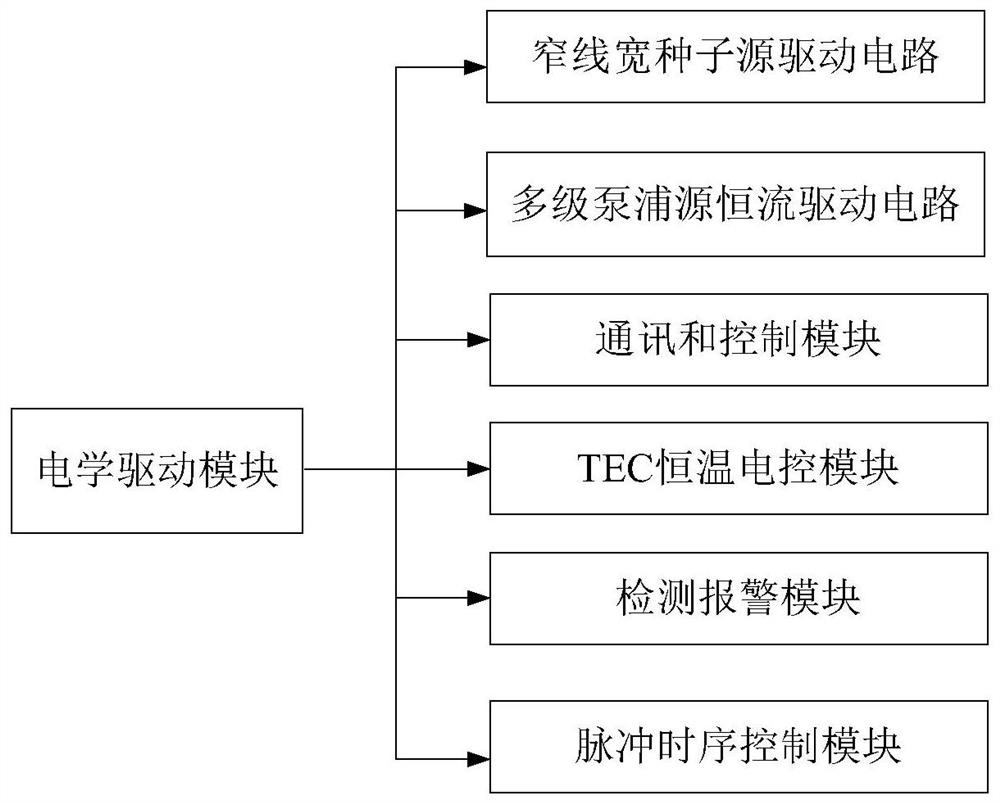

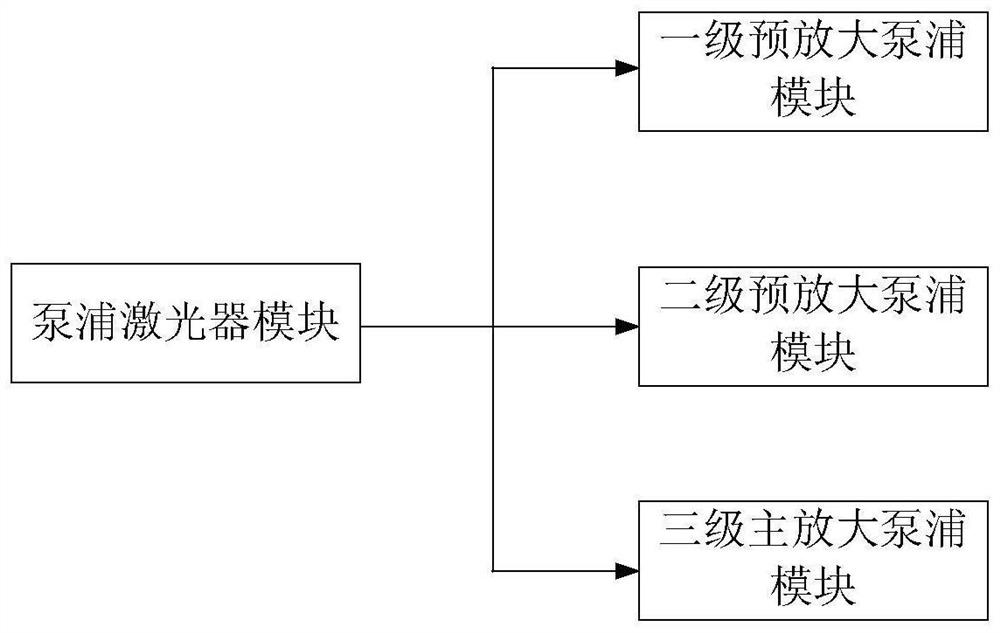

An all-fiber modular structure pump source and system for mid-infrared frequency conversion lasers

A technology of optical module and pump source, which is applied in the field of lasers, can solve problems such as the inability to guarantee the efficient operation of optical parametric oscillators, achieve the effects of reducing energy consumption and volume, ensuring beam quality, and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]Hereinafter, exemplary embodiments of embodiments of the present disclosure will be described in detail with reference to the accompanying drawings so that those skilled in the art can easily implement them. Also, for clarity, parts not related to describing the exemplary embodiments are omitted in the drawings.

[0038] In the embodiments of the present disclosure, it should be understood that terms such as "comprising" or "having" are intended to indicate the presence of features, numbers, steps, acts, components, parts or combinations thereof disclosed in this specification, and are not intended to The possibility that one or more other features, numbers, steps, acts, parts, parts or combinations thereof exist or be added is excluded.

[0039] In addition, it should be noted that, in the case of no conflict, the embodiments in the present disclosure and the features in the embodiments can be combined with each other. Embodiments of the present disclosure will be desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com