Large-scale curved-surface thin-wall part robot milling processing system and method

A technology of milling processing and robotics, which is applied in metal processing equipment, metal processing machine parts, manipulators, etc., can solve the problems of inability to directly feedback the end pose, low processing accuracy, and insufficient rigidity, and achieve automation of measurement and processing, and processing High precision and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

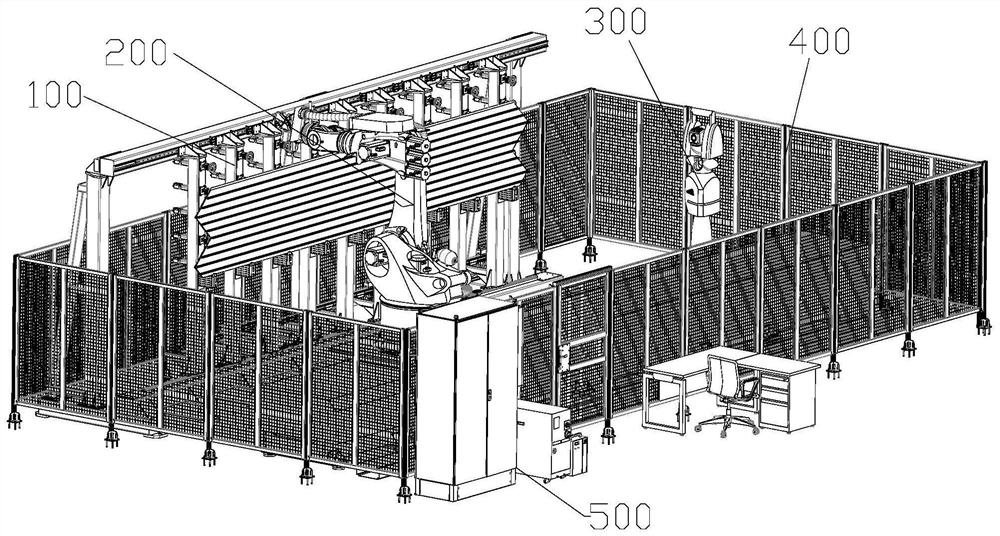

[0031] See figure 1 , the present invention has a flexible tooling unit 100, a robot milling unit 200, a tracking measurement unit 300, a safety protection unit 400, and a control unit 500; the robot milling unit 200 is installed on one side of the flexible tooling unit 100 fixed on the ground, and the tracking The measuring unit 300 is installed beside the robot milling unit 200 , the safety protection unit 400 surrounds the flexible tooling unit 100 , the robot milling unit 200 , and the tracking measurement unit 300 , and the control unit 500 is fixed outside the safety protection unit 400 . The control unit 500 is connected with the flexible tooling unit 100 , the robot milling unit 200 , and the tracking measurement unit 300 through lines to play a control role.

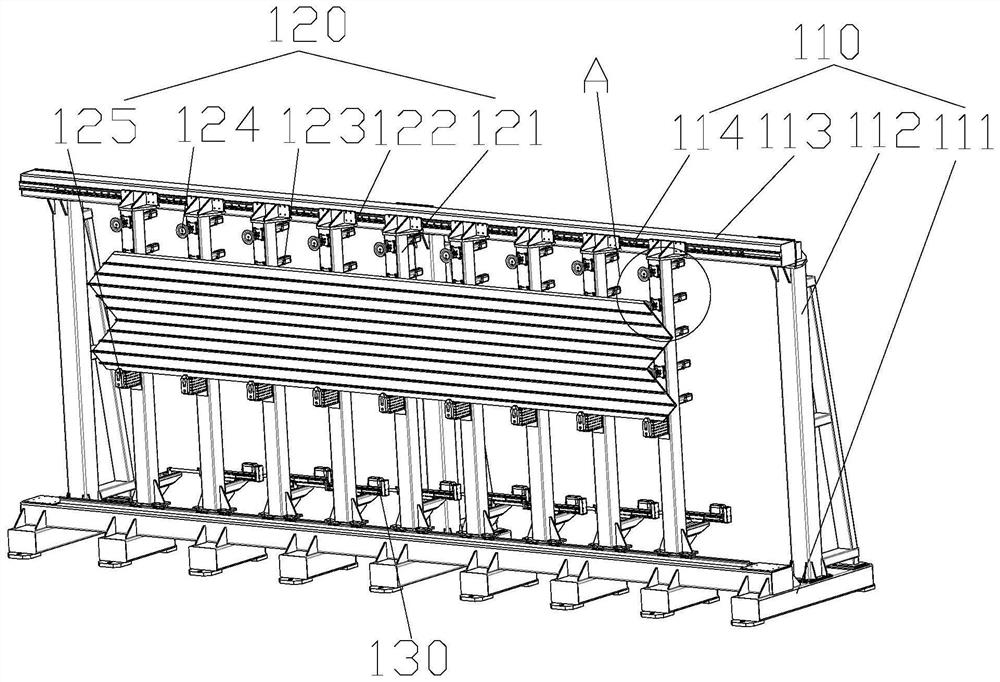

[0032] See figure 2 , Figure 5 , Image 6 , the flexible tooling unit 100 includes a tooling frame module 110, 9 servo flexible support modules 120 and 8 servo drive modules 130; the servo flexible support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com